Fuzzy PID control instrument and control method

A technology of fuzzy control algorithm and control method, applied in electric controllers, controllers with specific characteristics, etc., can solve problems such as unsatisfactory control effect, large control error, affecting automation control efficiency, etc., to improve efficiency and control effect. , the effect of reducing the overshoot problem and shortening the stability period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

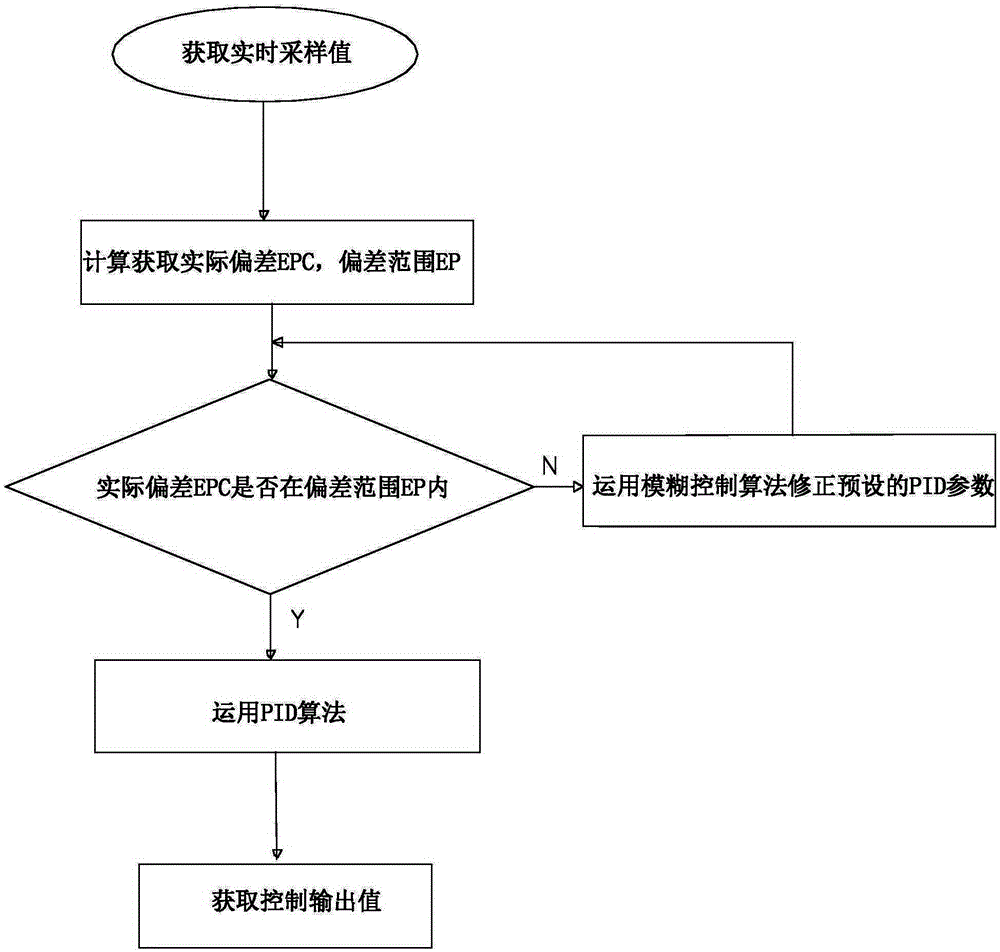

[0073] Please refer to figure 1 , the present embodiment provides a fuzzy PID control method, which may include:

[0074] S1: preset set value SV, and PID parameters including proportional gain P, integral time I and differential time D;

[0075] S2: Real-time collection of industrial signals of controlled equipment on the industrial site through sensors to obtain real-time sampling values;

[0076] S3: Calculate and obtain the actual deviation EPC according to the real-time sampling value and the set value SV, and obtain the deviation range EP according to the preset proportional gain P;

[0077] S4: Judging whether the actual deviation EPC falls outside the deviation range EP; obtaining the judgment result;

[0078] If the judgment result is that the actual deviation EPC is outside the deviation range EP, execute S41;

[0079] If the judgment result that the actual deviation EPC is within the deviation range EP, execute S42;

[0080] S41: first use the fuzzy control algo...

Embodiment 2

[0087] This embodiment is an extension of the solution of Embodiment 1, and the same content will not be repeated. The difference is that it also includes the process of preprocessing the real-time sampling values collected in real time in S2, specifically including:

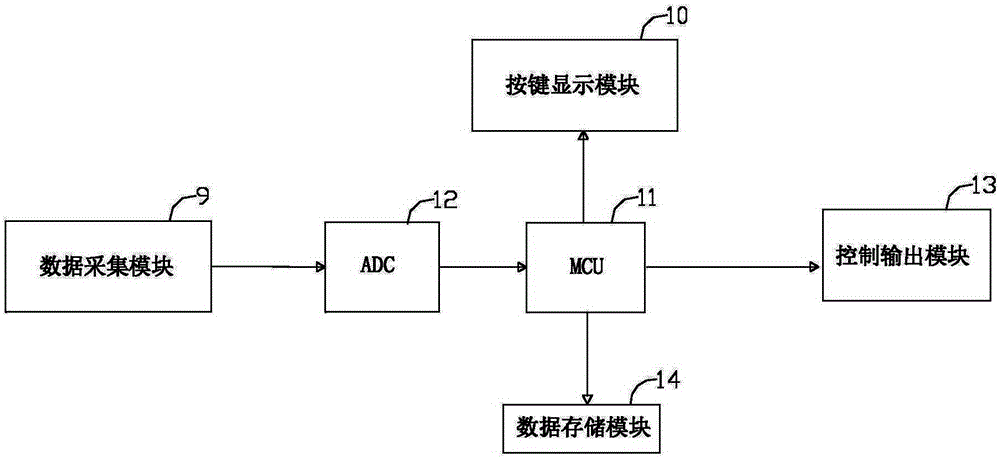

[0088] S21: Sequentially perform gating, filtering and op-amp processing on the real-time sampling value, and then transmit it to the digital-to-analog conversion module, convert the simulated real-time sampling value into a real-time sampling value digital signal, and then transmit it to the microprocessor MCU11;

[0089] S22: the microprocessor MCU11 samples the real-time sampled value digital signal according to multiple time-sharing samples in a sampling period, obtains the sampled value after the average filtering, and saves the average sampled value in the data memory as an effective real-time sampled value, It is used to calculate the subsequent actual deviation EPC.

[0090] The preset parameter in the...

Embodiment 3

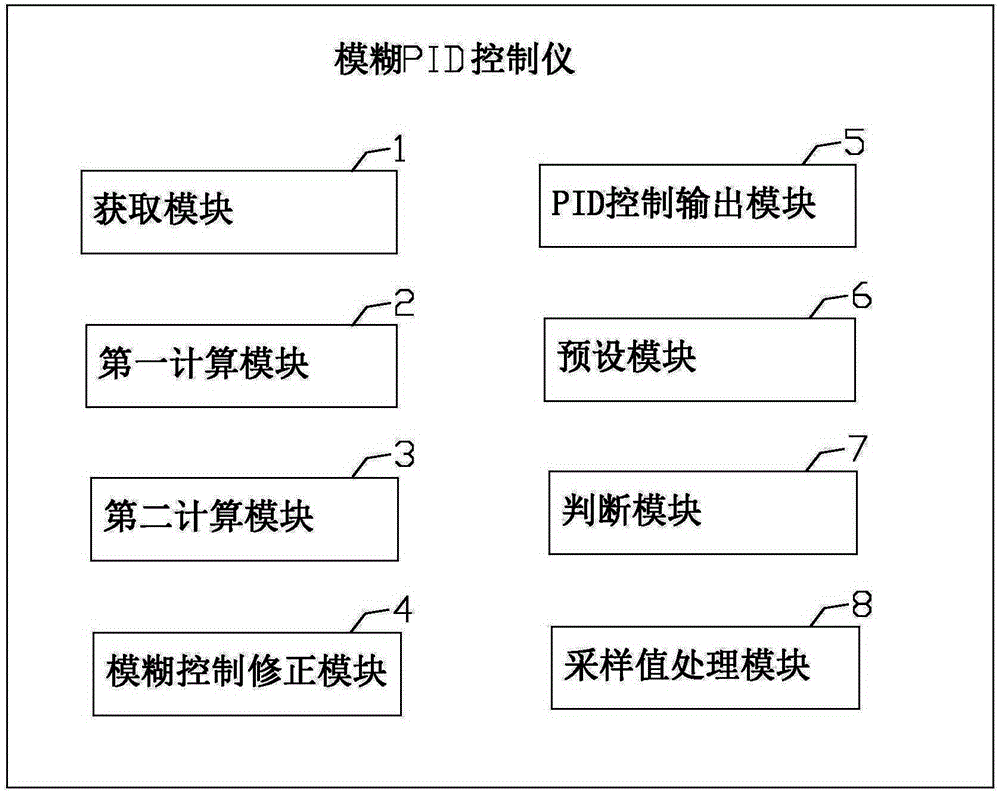

[0093] see figure 2 , providing a fuzzy PID controller, comprising:

[0094] Obtaining module 1, used to obtain real-time sampling values;

[0095] The sampled value processing module 8 is used to sequentially perform gating, filtering and op-amp processing on the real-time sampled value, and then convert it into a real-time sampled value digital signal;

[0096] The time-sharing sampling module is used to sample the real-time sampled value digital signal multiple times in a sampling cycle to obtain an average sampled value, and then use the average sampled value as an effective real-time sampled value to calculate the actual deviation EPC .

[0097] The preset module 6 is used to preset the set value and PID parameters including proportional gain P, integral time I and differential time D;

[0098] The first calculation module 2 is used to calculate and obtain the actual deviation EPC according to the real-time sampling value and the set value;

[0099] The second calcul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com