Cylindrical frequency selective surface structure

A technology of frequency selective surface and cylinder, applied in the direction of radiation unit cover, waveguide type devices, electrical components, etc., can solve problems such as poor filtering characteristics and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

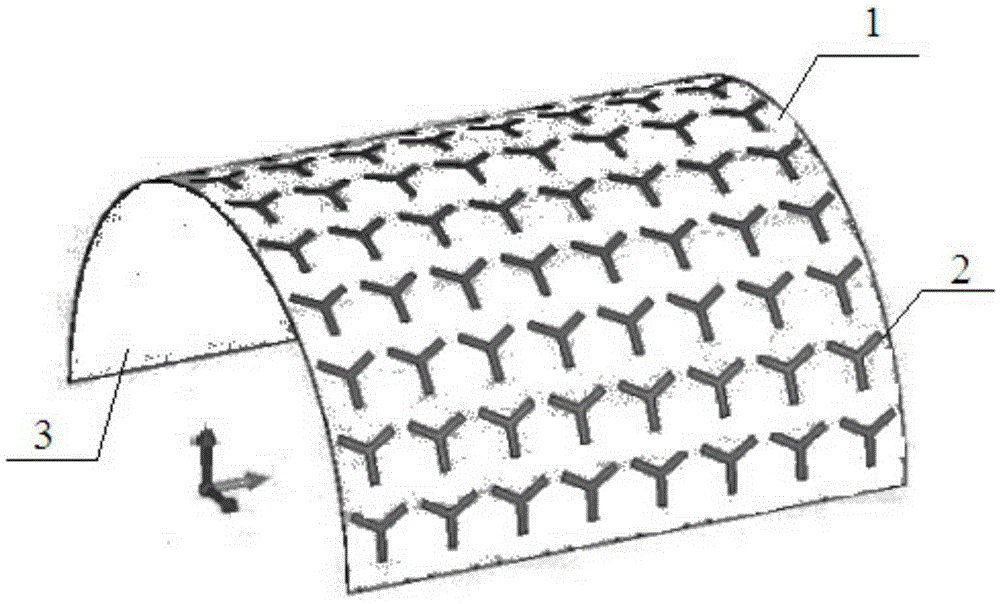

[0019] Specific implementation mode 1. Combination figure 1 Describe this embodiment, the cylindrical frequency selective surface structure described in this embodiment, it comprises metal plate 1 and the dielectric layer 3 that thickness is 1mm, the dielectric constant of described dielectric layer 3 is 2.2, and magnetic permeability is 1; The surface of the metal plate 1 is engraved with a through hole 2 in the shape of a rectangular grid, the shape of the through hole 2 is Y-shaped, and the distance between every two adjacent Y-shaped holes along the column surface is 40mm. The metal plate 1 According to the cylindrical curvature with a radius of curvature of 160mm, the dielectric layer 3 is attached to the inner side of the metal plate 1 .

[0020] The material of the metal plate described in this embodiment is a metal with high electrical conductivity.

specific Embodiment approach 2

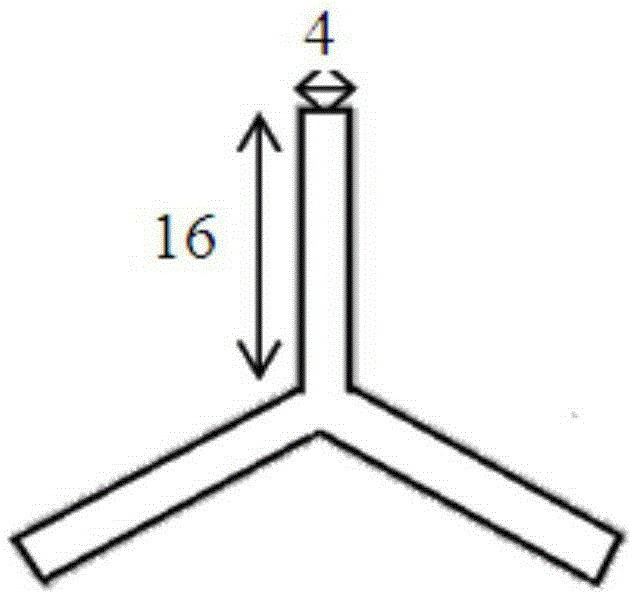

[0021] Embodiment 2. This embodiment is a further description of the cylindrical frequency selective surface described in Embodiment 1. The length of the three arms of the Y-shaped hole is 16 mm, and the width is 4 mm.

specific Embodiment approach 3

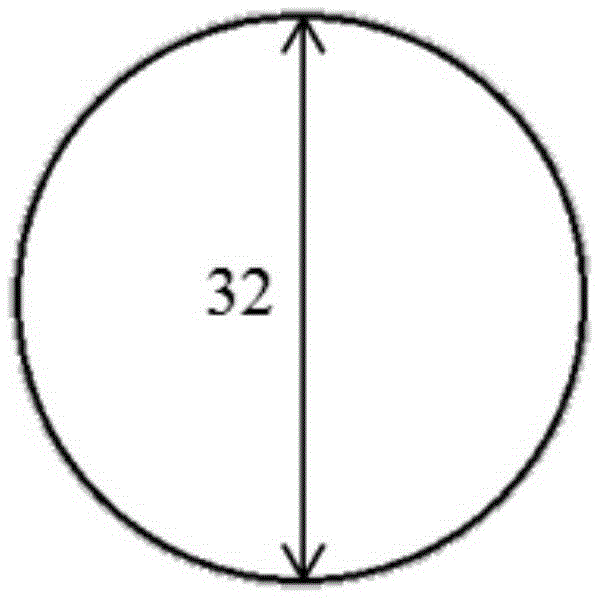

[0022] Specific implementation mode three, combination image 3 Describe this embodiment, this embodiment is the difference between the cylindrical surface frequency selection surface structure described in Embodiment 1, that the shape of the through hole 2 is a circular hole, the diameter of the circular hole is 32 mm, and every two circular holes The distance between the edges along the cylindrical direction of the dielectric layer is 8mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com