Multi-filling primary forming mold

A primary forming and filling technology, which is applied in baking, dough processing, food science, etc., can solve the problems of injection, the inability to realize solid filling and liquid filling, and the inability to realize multiple filling injections, so as to avoid damage, The effect of rich variety of fillings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

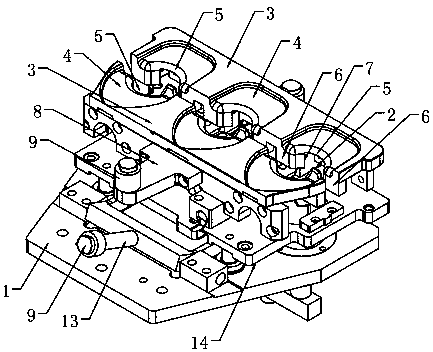

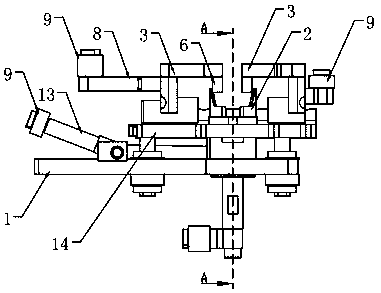

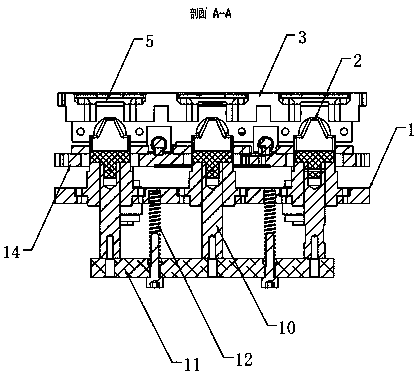

[0042] A multi-filling primary forming mold includes a mounting plate 1, on which a mold core 2 and two skin-connecting plates 3 capable of relative movement are arranged, and the skin-connecting plates 3 are respectively arranged on the sides of the mold core 2 On both sides, the upper surface of the skin grafting plate 3 is provided with a concave step 4 for realizing the skin grafting function, and the adjacent sides of the two skin grafting plates 3 are provided with grooves 5 for realizing the initial forming of the skin, and each concave The left and right ends of the groove 5 are provided with pressing parts 6 , and the opposite grooves 5 on the two skin plates 3 form a group of preliminary formed grooves 5 . The adjacent sides of the two skin-connecting plates 3 on the multi-filling preliminary forming mold are provided with grooves 5 for realizing the initial forming of the dough, and the left and right ends of each groove 5 are provided with pressing parts 6, two The...

Embodiment 2

[0044] A multi-filling primary forming mold includes a mounting plate 1, on which a mold core 2 and two skin-connecting plates 3 capable of relative movement are arranged, and the skin-connecting plates 3 are respectively arranged on the sides of the mold core 2 On both sides, the upper surface of the skin grafting plate 3 is provided with a concave step 4 for realizing the skin grafting function, and the adjacent sides of the two skin grafting plates 3 are provided with grooves 5 for realizing the initial forming of the skin, and each concave The left and right ends of the groove 5 are provided with pressing parts 6 , and the opposite grooves 5 on the two skin plates 3 form a group of preliminary formed grooves 5 .

[0045] The number of grooves 5 on the two skin-connecting plates 3 is the same.

[0046] Each skin grafting plate 3 is provided with at least three horizontally linearly distributed grooves 5, and two skin grafting plates 3 jointly form at least three horizontall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com