A carbonaceous heat source with both self-extinguishing and anti-shedding functions

A carbonaceous heat source, anti-shedding technology, applied in the application, manufacture of cigars, tobacco and other directions, to achieve the effect of safe and non-toxic raw materials, sufficient sources, and inhibition of carbonaceous heat source shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The raw materials of the carbonaceous heat source of the present invention include the following components: 65g of carbon powder, 4g of guar gum, 8g of potassium alginate, 13g of calcium carbonate, 5g of potassium carbonate, 4g of potassium nitrate and 1g of iron oxide.

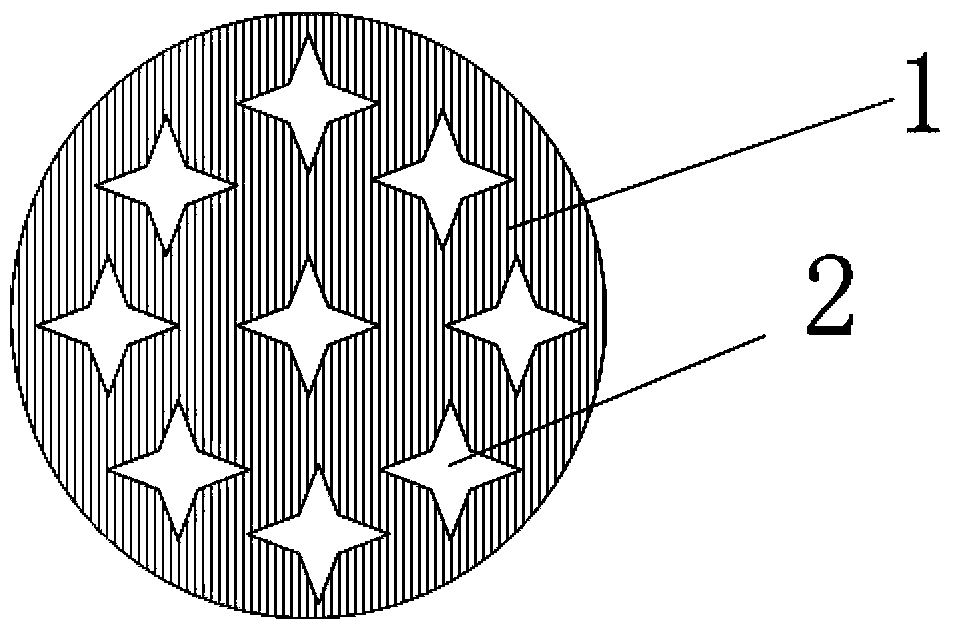

[0034] Mix the above components with a mold and make a cylindrical heat source with multiple five-pointed star-shaped longitudinal channels, the length of which is 15mm, and the internal void occupies 65% of the total volume of the heat source. figure 1 .

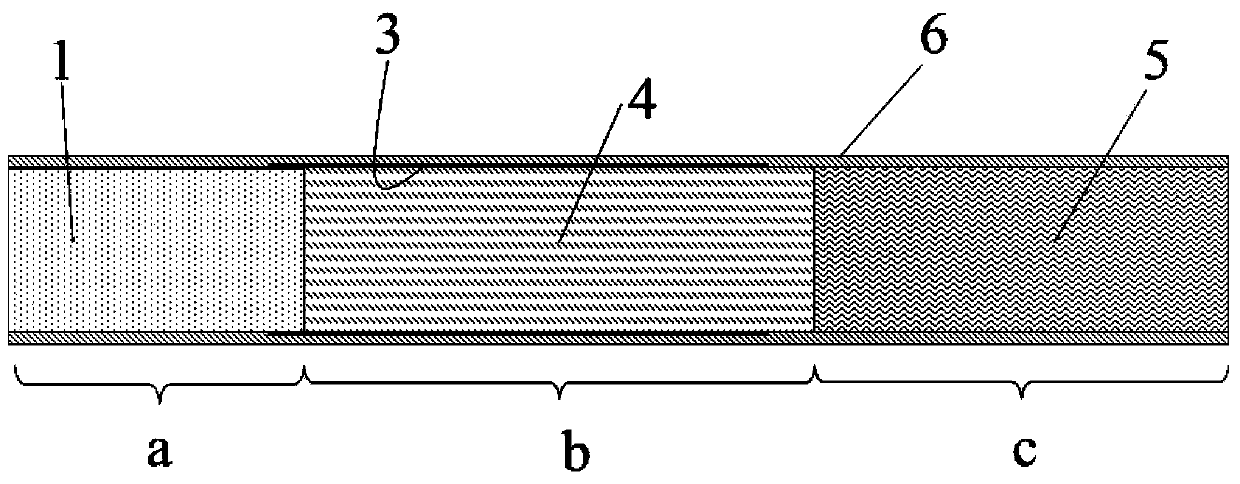

[0035] figure 2 It is a schematic diagram of a longitudinal section of a carbon-heated cigarette. It can be seen that the cigarette is composed of a carbonaceous heat source area a, a smoke forming area b and a filter tip area c. The carbonaceous heat source area a is composed of cigarette paper 6, aluminum foil paper 3 and carbonaceous heat source 1, and the length of the aluminum foil paper in the longitudinal direction is 1 / 3 to 1 / 2 of the le...

Embodiment 2

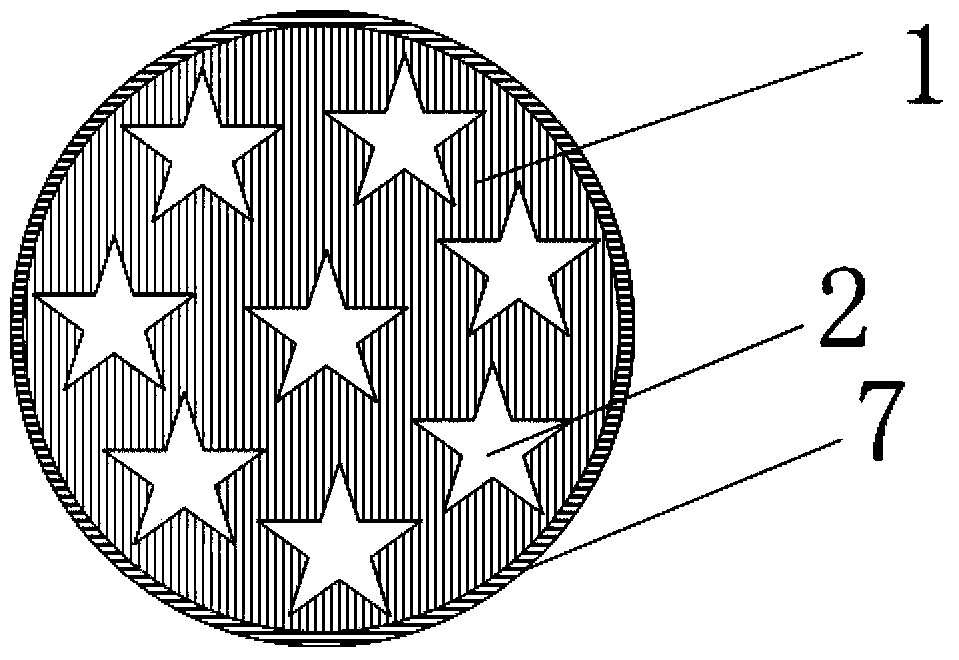

[0037] 20g guar gum, 50g vermiculite powder (200 mesh), 30g graphite powder (200 mesh) and 1g paraffin oil are sent into the extruder and mixed to make a bag with a thickness of 1000 μm and a width of 3.5mm, and tightly Wrap one end of the fixed section of the carbonaceous heat source prepared in Example 1 to obtain a carbonaceous heat source with both self-extinguishing and anti-shedding functions. The cross-sectional structure of the fixed section of the carbonaceous heat source is as follows: image 3 shown.

Embodiment 3

[0039] 15g guar gum, 45g vermiculite powder (400 orders), 40g graphite powder (150 orders) and 1.5g corn oil are sent into the extruder and mixed and made into a bag with a thickness of 700 μm and a width of 4.0mm. Tightly wrap one end of the fixed section of the carbonaceous heat source prepared in Example 1 to obtain a carbonaceous heat source with both self-extinguishing and anti-shedding functions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com