Making method of pure titanium tooth, and method for autotransplanting by means of pure titanium tooth

A production method, pure titanium technology, applied in the direction of dental prosthesis, dental implants, dentures, etc., can solve the problems of periodontal ligament damage of transplanted teeth, restore masticatory function, reduce inflammatory reactions, and avoid absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

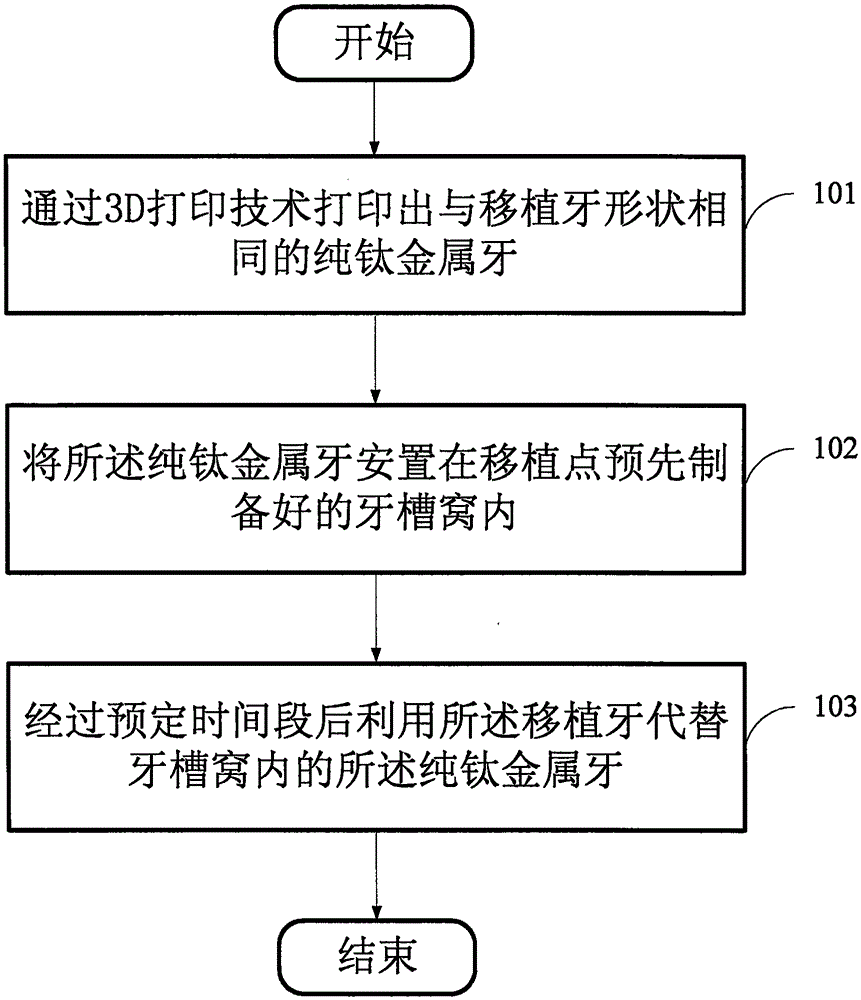

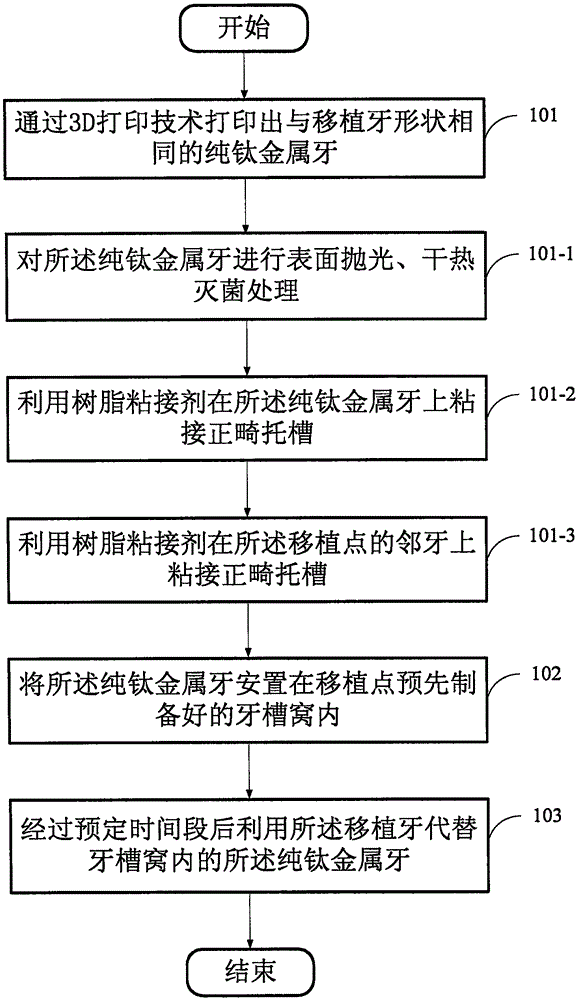

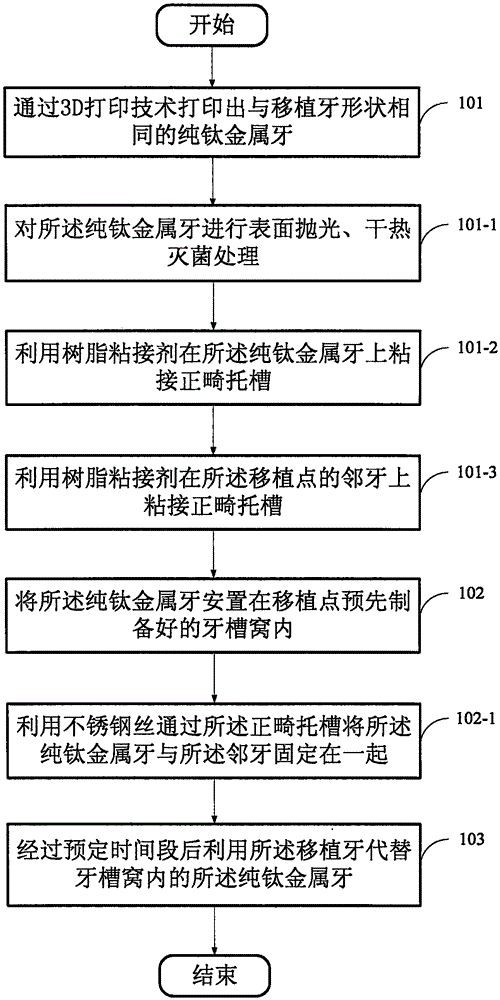

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 provides a method for making pure titanium teeth, using chemical components: titanium, aluminum, alum, nitrogen, carbon, hydrogen, iron, oxygen, and with a yield strength of 950MPa, a tensile strength of 1005Mpa, and 10% Elongation, elastic modulus of 115Mpa, 4.5g / cm 3 Density, melting point range of 1604-16551, 10.16×10 -6 K -1 The expansion coefficient is used to make pure titanium teeth.

[0032] Wherein, the color of the titanium metal tooth prepared by adopting the manufacturing method of the pure titanium tooth can be white or silvery white.

[0033] Among them, the pure titanium tooth is printed by 3D printing technology

[0034] Among them, the proportion of titanium, aluminum, alum, nitrogen, carbon, hydrogen, iron and oxygen used in the production method of pure titanium teeth can be: titanium, 90%; aluminum, 6%; alum, 4%.

[0035] Among them, the proportion of titanium, aluminum, alum, nitrogen, carbon, hydrogen, iron and oxygen used in the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com