Solid-powder dissolving and adding device

A solid powder and adding device technology, applied in the direction of dissolution, dissolution, transportation and packaging, etc., can solve the problems of unstable solution concentration, low dissolution efficiency, incomplete dissolution, etc., and achieve fast dissolution speed, high overall efficiency, and automation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

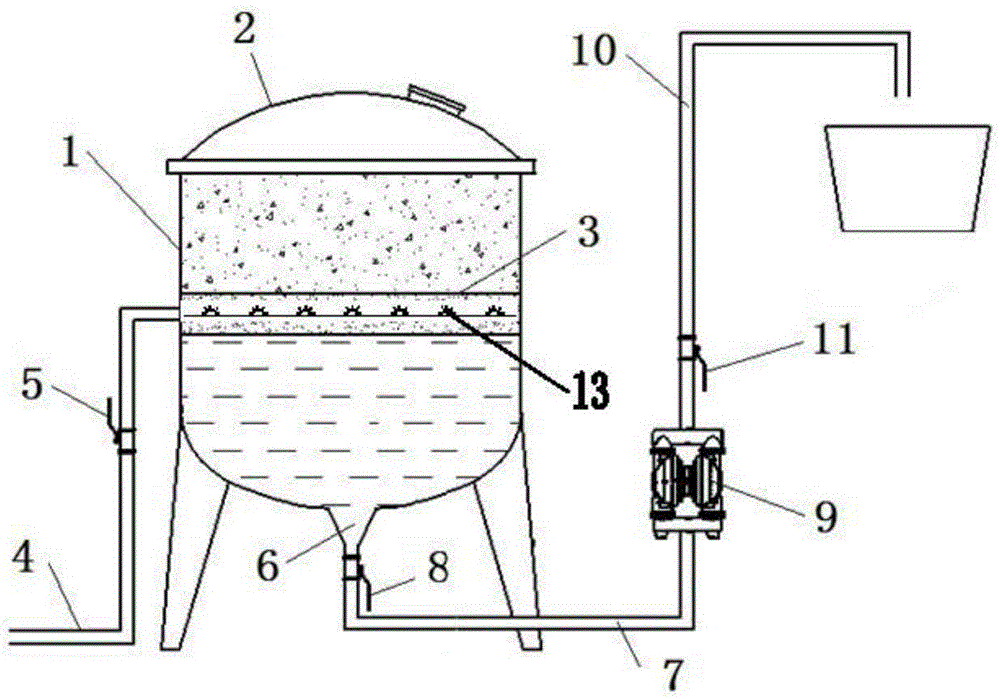

[0021] Such as figure 1 As shown, the present invention is provided with dissolving tank 1, and the top of dissolving tank 1 is provided with tank cover 2, and the bottom is supported by supporting feet. The inside of the dissolving tank 1 is provided with a grate 3, the diameter of the grate 3 is the same as the inner diameter of the dissolving tank 1, and the grate 3 is provided with holes and several nozzles 13. On the dissolving tank 1, a water inlet pipe 4 is connected to the position corresponding to the grate 3, and the water inlet pipe 4 communicates with the above-mentioned nozzle 13, and the water inlet pipe 4 is also provided with a water inlet valve 5.

[0022] The bottom of the dissolving tank 1 is provided with a liquid outlet 6, and the liquid outlet 6 is connected with a liquid outlet pipe 7, and the liquid outlet pipe 7 is provided with a liquid outlet valve 8. The liquid outlet pipe 7 is connected with a pump 9, and the other end of the pump 9 is connected w...

Embodiment 2

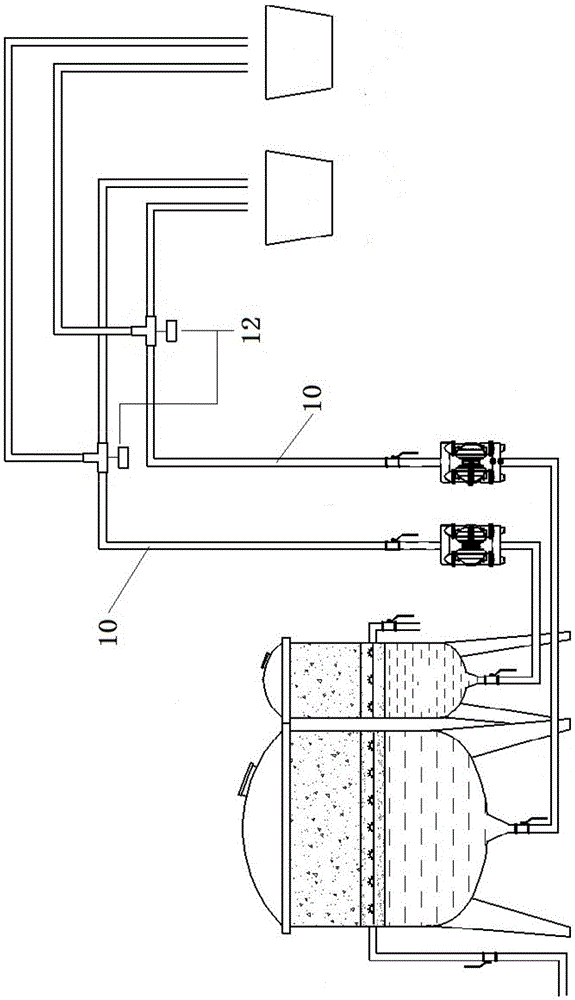

[0027] Such as figure 2 As shown, the present embodiment is a combination of two sets of embodiment 1. In actual working conditions, there are many situations where different dissolving solutions need to be mixed, and this embodiment achieves such an effect. In this embodiment, three-way valves 12 are provided on the two adding pipes 10. The three-way valves 12 not only realize the mixing of two different dissolving solutions, but also divide the mixed solution into two parts, which is more convenient and practical.

[0028] The dissolved liquid in the present invention can also directly enter the equipment to be added from the liquid outlet pipe 7, saving cost. The setting of the pump 9, the adding pipe 10 and the adding valve 11 makes the adding speed faster and the efficiency is higher. In the present invention, more than two sets of solid dissolving and adding devices can be installed as in Embodiment 1, so as to easily realize mixing and subpackaging of different disso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com