Multifunctional vibrating-type screening device for corn grains

A screening device and technology of corn kernels, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of corn impurities, low work efficiency, a large amount of dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

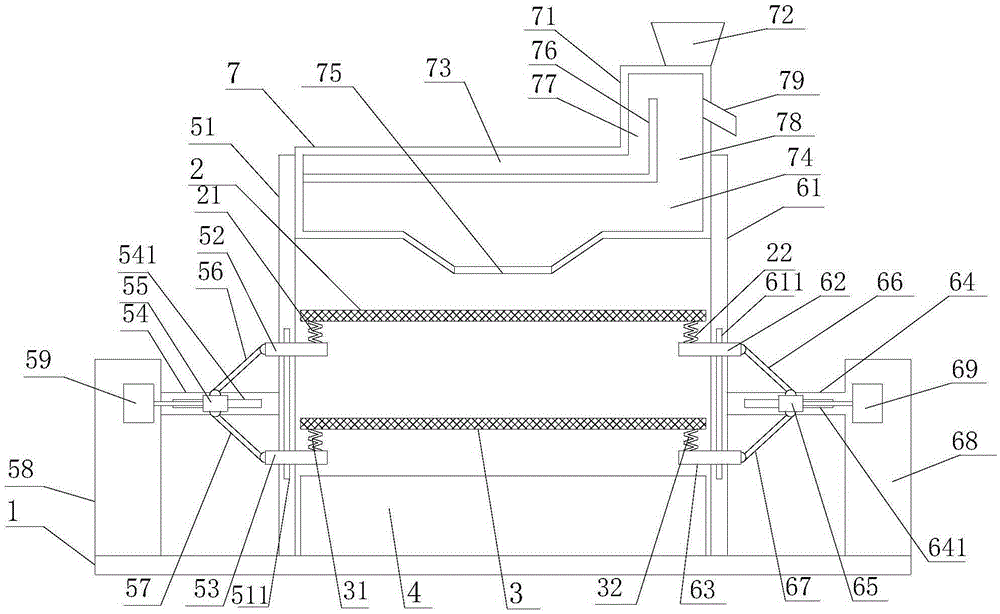

[0019] refer to figure 1 , the present invention proposes a multifunctional vibrating corn grain screening device, comprising a base 1, a screening device, a feeding device for feeding to the screening device, and the screening device includes a first sieve plate 2, a second sieve plate 3, a collecting The box 4 and the first drive mechanism and the second drive mechanism that drive the first sieve plate 2 and the second sieve plate 3 to vibrate up and down, the collection box 4 is arranged on the base 1, the feeding device, the first sieve plate 2, the second sieve plate The plate 3 and the collection box 4 are arranged vertically from top to bottom, wherein:

[0020] The first drive mechanism includes a first pole 51 installed on the base 1, a first mounting plate 53, a second mounting plate 53, a first slider 55, a first support plate 54, a first connecting rod 56, a second connecting rod Rod 57, the first column 58 and the first driving cylinder 59, the first pole 51 is v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com