Single-inductive and double-pneumatic cylinder perforating fixture

A punching fixture and cylinder technology, applied in the field of tooling fixtures, can solve the problems of not being able to improve the accuracy and precision of punching, and achieve the effect of improving accuracy and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

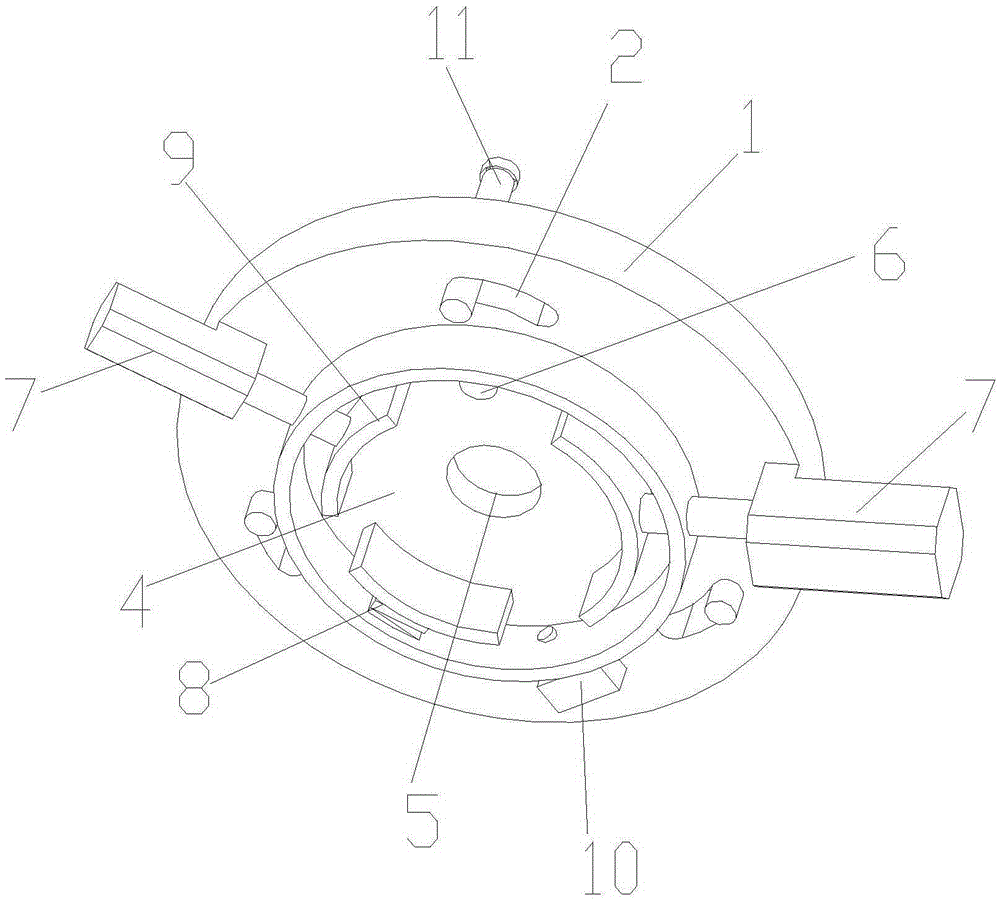

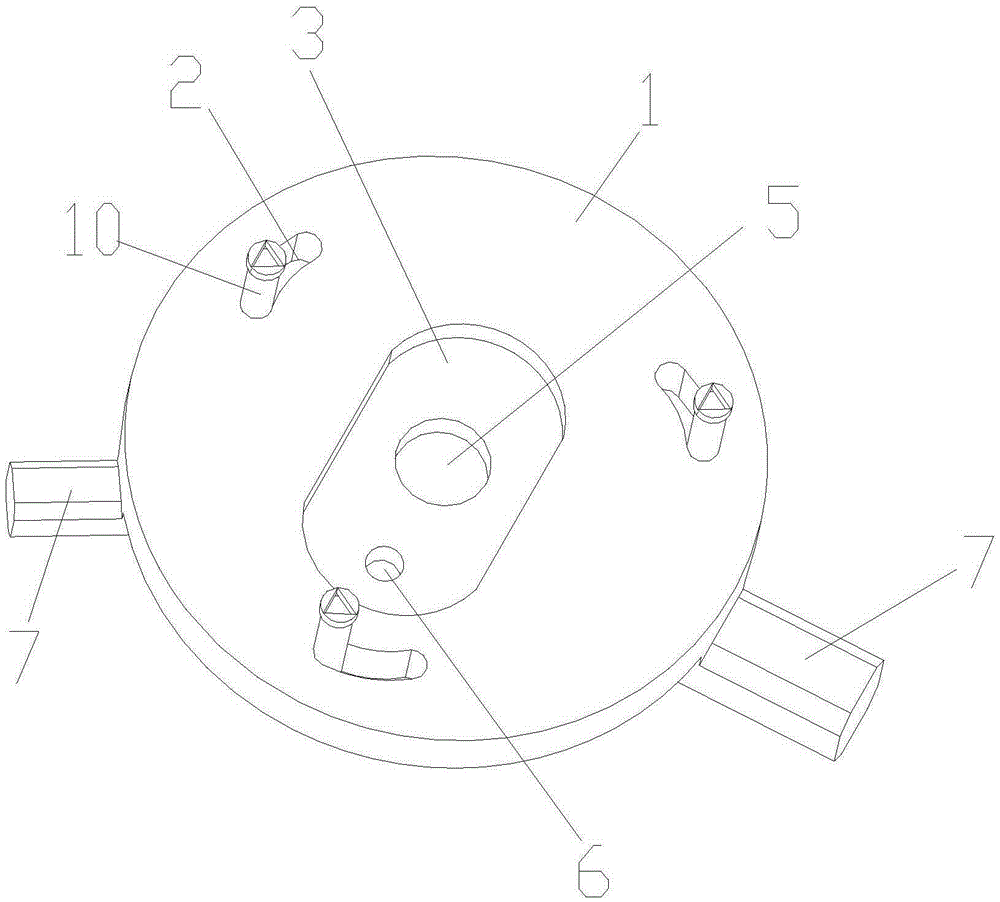

[0014] as attached figure 1 , 2 Shown is a single-induction double-pneumatic cylinder punching fixture according to the present invention, including a fixed plate 1; arc-shaped grooves 2 are evenly distributed on the fixed plate 1, and the number of arc-shaped grooves 2 is 3. And each arc-shaped groove 2 is distributed at 120°, and fixed bolts 11 are provided in the arc-shaped groove 2; one side of the fixed plate 1 is provided with a drill groove 3, and the other side is provided with a cylinder groove 4; the drill groove 3 is provided with a drill hole 5; one side of the drill hole 5 is provided with an alignment hole 6; the cylinder groove 4 is provided with two arc-shaped plates 9 controlled by a compression cylinder 7 and one connected by a spring 8 The arc plate 9; the two compression cylinders 7 are controlled by a sensor 10 to expand and contract.

[0015] When in use, first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com