A ducted fan vector propulsion system

A vector propulsion, ducted fan technology, applied in aircraft parts, aircraft control, propellers and other directions, can solve the problems of heavy structure, complex driving mechanism, large aerodynamic resistance of airflow deflection mechanism, etc., to reduce aerodynamic resistance and improve flight performance. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

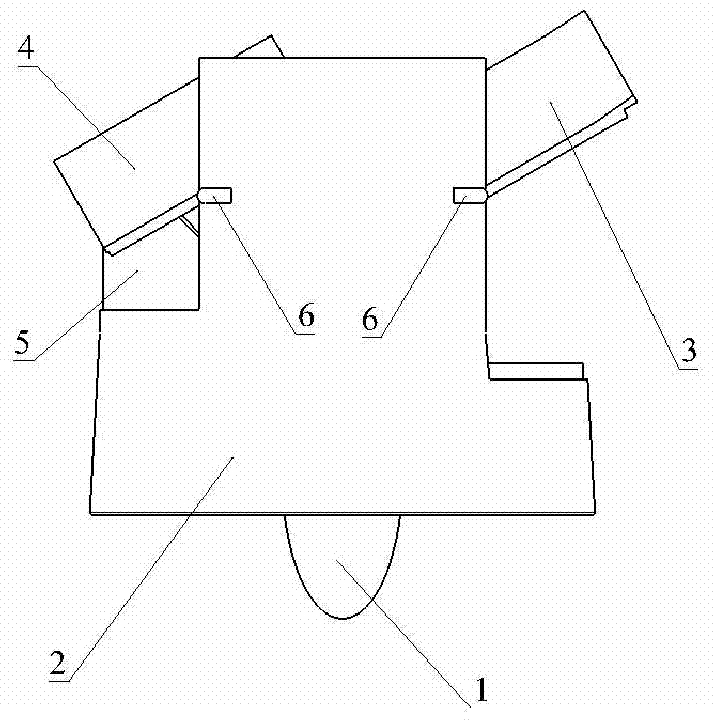

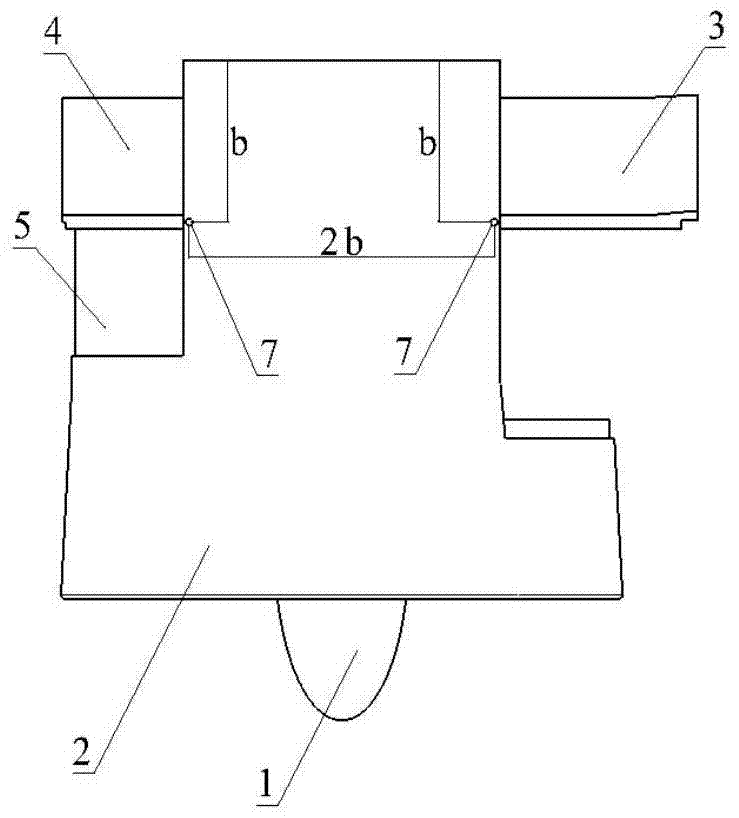

[0047] The present embodiment is used for the ducted fan vector propulsion system on the rotor / wing conversion type aircraft, and the whole device is installed at the tail of this type of aircraft.

[0048] Such as figure 1 and Figure 8 As shown, this embodiment includes a ducted propeller and an airflow deflection mechanism for changing the deflection direction of the airflow.

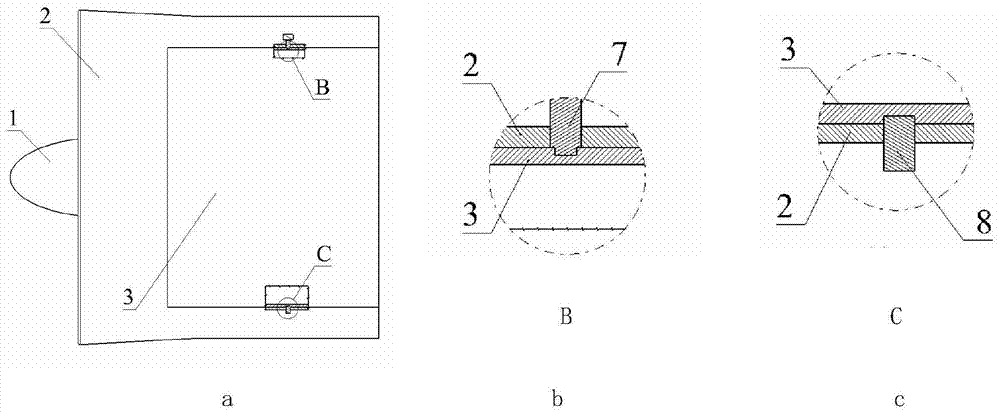

[0049] The ducted propeller includes a propeller 1 which rotates to generate airflow and a ducted cylinder 2 surrounding the propeller.

[0050] The airflow deflection mechanism includes a first rotating piece 3 , a second rotating piece 4 , a blocking piece 5 , a reduction motor 6 , a rotating drive shaft 7 and a rotating support shaft 8 . Wherein, the first rotating piece 3 , the second rotating piece 4 and the blocking piece 5 are all formed by cutting from the duct cylinder 2 . specifically is:

[0051] The first rotating piece 3 and the second rotating piece 4 are cut symmetrically on the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com