Aerodynamic layout of aircraft with blended wing body

A technology of wing-body fusion and aerodynamic layout, which is applied in the field of aircraft, can solve the problems of increasing aircraft resistance, large thickness of the central fuselage, and affecting take-off and landing performance, so as to increase the maximum lift coefficient, increase the layout area, and improve take-off and landing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

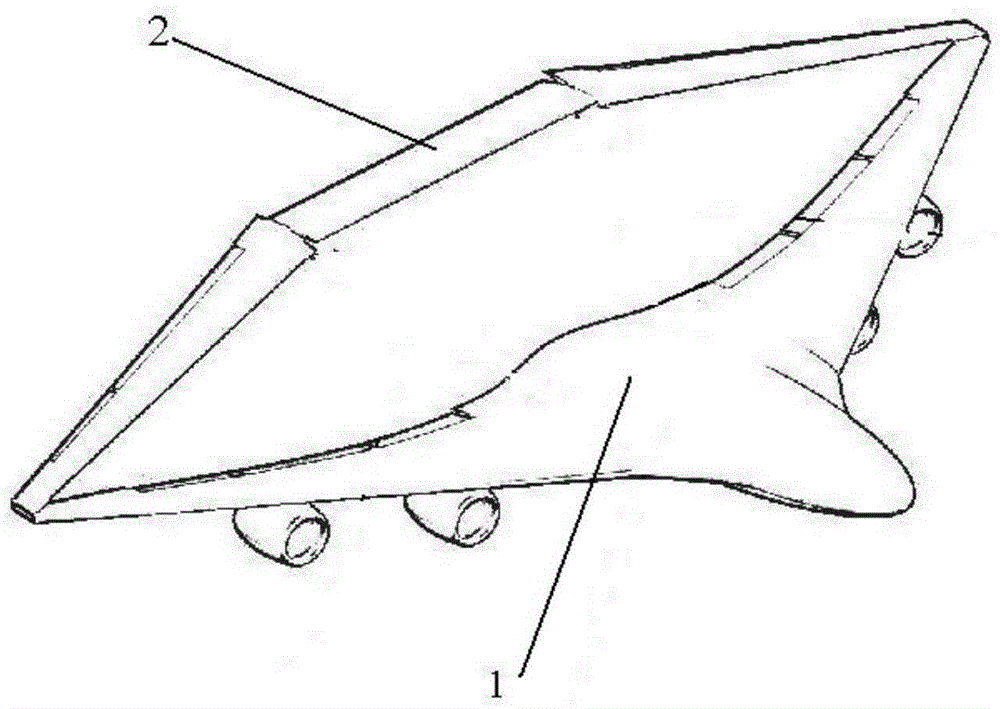

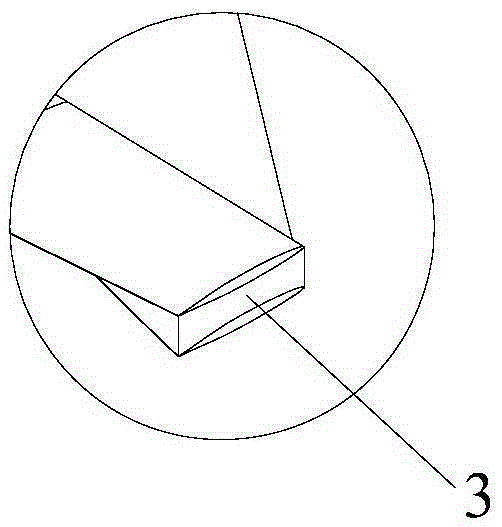

[0028] This embodiment provides an aerodynamic layout of a wing-body fusion aircraft, such as figure 1 Shown, it comprises wing-body fusion part, and the fuselage of wing-body fusion part fuses with wing and forms front wing 1, also comprises rear wing, and rear wing is flat tail 2, and the both sides of flat tail 2 and front machine The two sides of the wing 1 are respectively connected by connecting pieces 3 .

[0029] This embodiment is based on the aerodynamic layout of the wing-body fusion aircraft. The fuselage and the wings of the aircraft are integrated without obvious boundaries. Both the fuselage and the front wings can generate lift. Therefore, the original wing The fusion portion of the body is called the front wing. In this application, on the basis of wing-body fusion, adding a pair of flat tails as the rear wing can improve the lift of the wing-body fusion aircraft, and increase the layout area of the lift-increasing device and the operating device, improve t...

Embodiment 2

[0035] This embodiment provides an aerodynamic layout of a wing-body fusion aircraft, the structure of which is basically the same as in Embodiment 1: comprising the wing-body fusion portion, the fuselage and the wing of the wing-body fusion portion merge to form the front wing, and also include The rear wing is a flat tail, and the two sides of the flat tail are respectively connected with the two sides of the front wing by connecting pieces.

[0036] The difference is that at least part of the flat tail is a full motion setup.

[0037] In the present embodiment, at least part of the flat tail is set with full motion, and the overall change of the flat tail can be made at a smaller angle in the cruising stage, so that the aircraft reaches a trim state, improves the rudder effect, and improves the longitudinal and directional maneuverability of the aircraft; the full-motion flat tail can also be It acts as a lift-increasing device to improve the take-off and landing performanc...

Embodiment 3

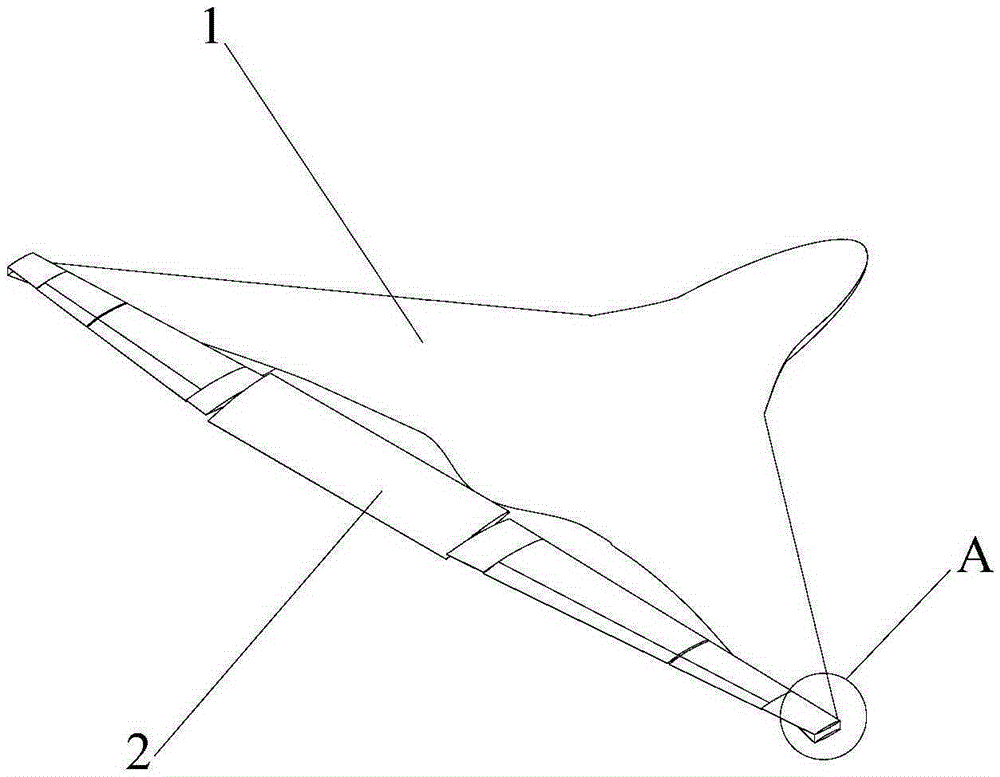

[0039] This embodiment provides an aerodynamic layout of a wing-body fusion aircraft, the structure of which is basically the same as in Embodiment 2: the wing-body fusion portion is included, the fuselage and the wing of the wing-body fusion portion are merged to form the front wing 1, and Including the rear wing, the rear wing is a horizontal tail 2, the two sides of the horizontal tail 2 are respectively connected with the two sides of the front wing 1 through the connecting piece 3, and at least part of the horizontal tail 2 is set for full motion.

[0040] Its difference: as Figure 4 As shown, it also includes at least two vertical tails 4, considering the simplicity and compactness of the aircraft structure, preferably, two vertical tails 4 are set, and the two ends of the two vertical tails 4 are connected to the rear end of the front wing 1 respectively. The horizontal tail 2 is connected, and the horizontal tail 2 placed between the two vertical tails 4 is a full-mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com