Aircraft towing intelligent robot

An intelligent robot and aircraft towing technology, which is applied to aircraft parts, ground equipment, transportation and packaging, etc., can solve the problems of complex operation and low work efficiency, and achieve the effect of precise mobile positioning, low operating cost and dexterous fuselage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

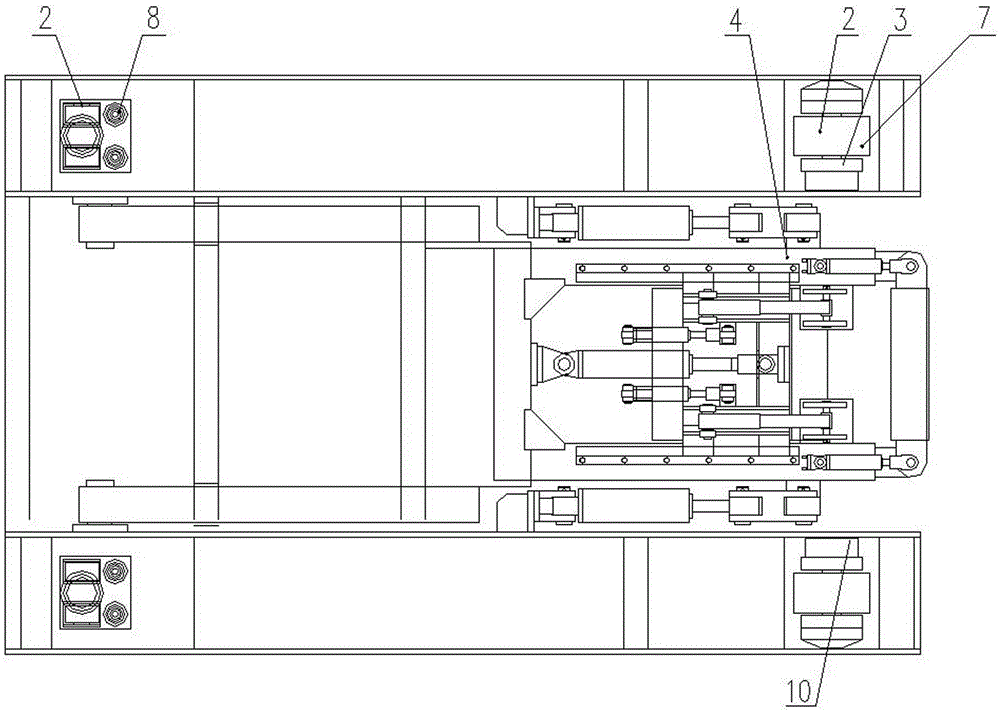

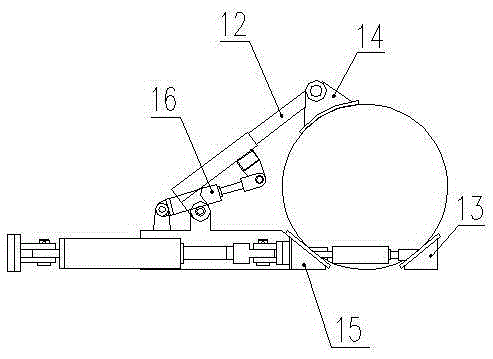

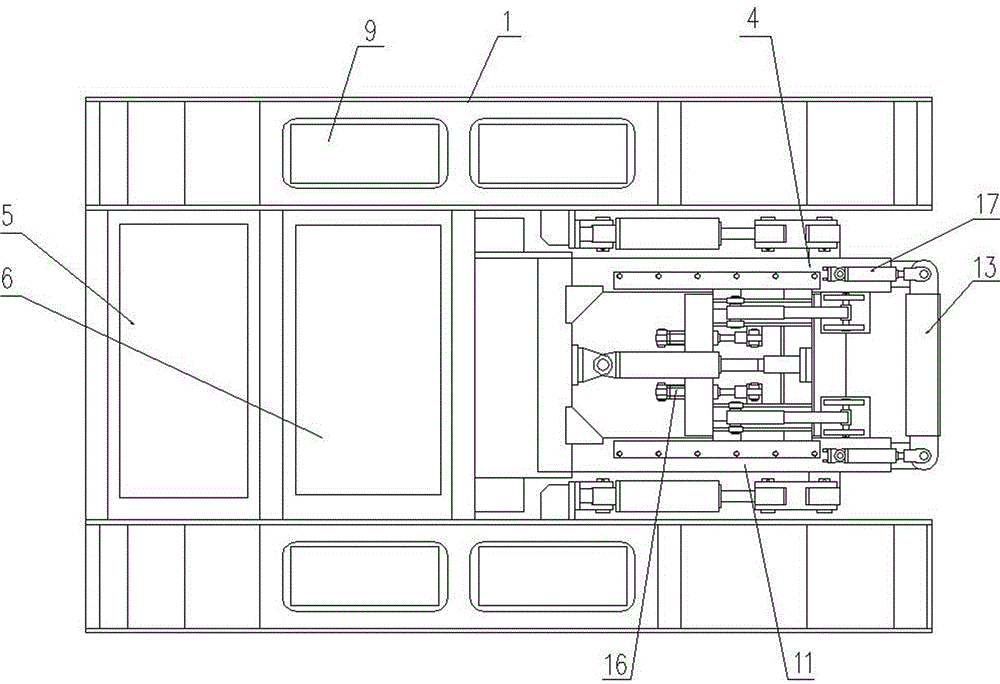

[0016] see figure 1 , is a structural schematic diagram of the present invention, an aircraft towing intelligent robot includes a driving system 2, a braking system 3, a clamping and lifting system 4, a hydraulic system 5 and an electrical system 6 arranged on a transport mechanism.

[0017] The transportation mechanism includes a drive system 2 and a car body chassis device 1. The drive system 2 includes a drive wheel set 7, a driven wheel set 8 and a battery pack 9. Both the drive wheel set 7 and the driven wheel set 8 are polyurethane rubber-coated wheels, and the drive wheel set 7 and the wheels of the driven wheel group 8 are supported and installed on the chassis 1 of the vehicle body by bearing housings, the driving wheel group 7 can be driven and adjusted in speed, the battery pack 9 is installed on the chassis 1 of the vehicle body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com