Valve-type quick-change liner unit for discharge hoppers

A valve type and lining plate technology, applied in the field of valve type quick-change lining plate device, can solve the problems of limited space height, shutdown of transportation system, narrow internal space, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

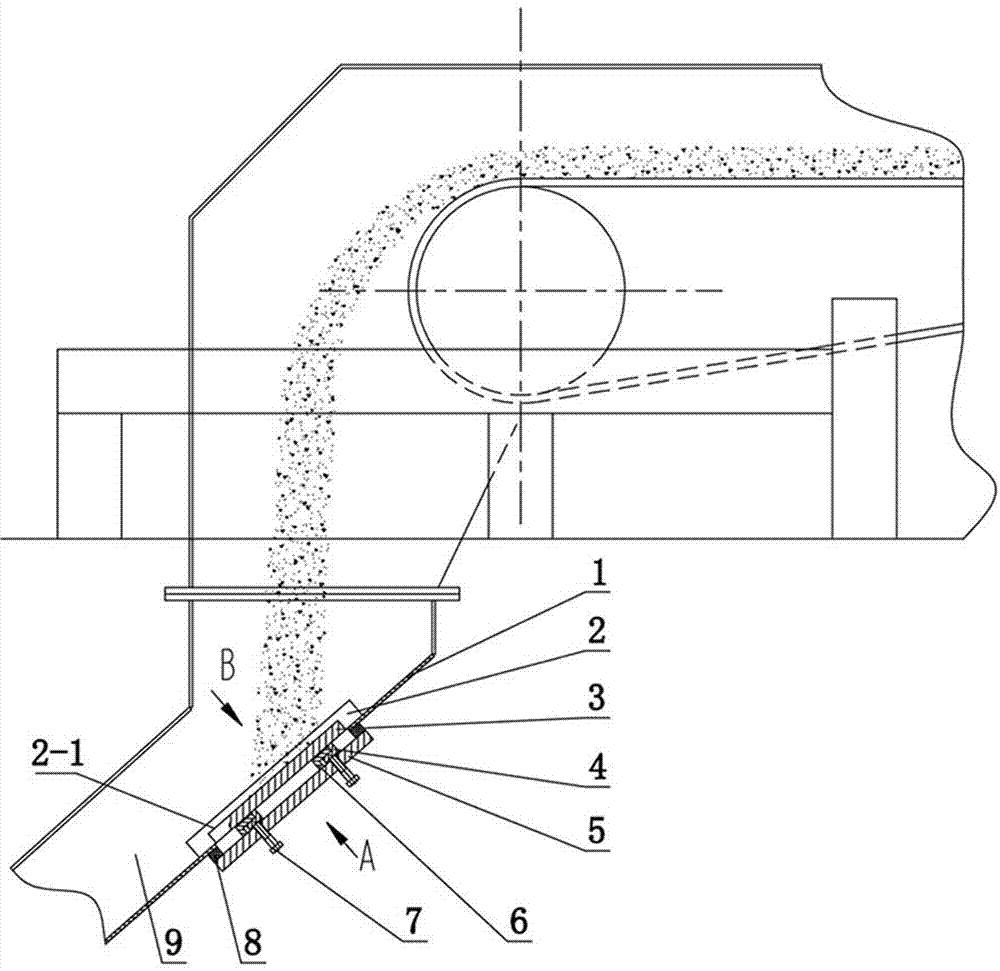

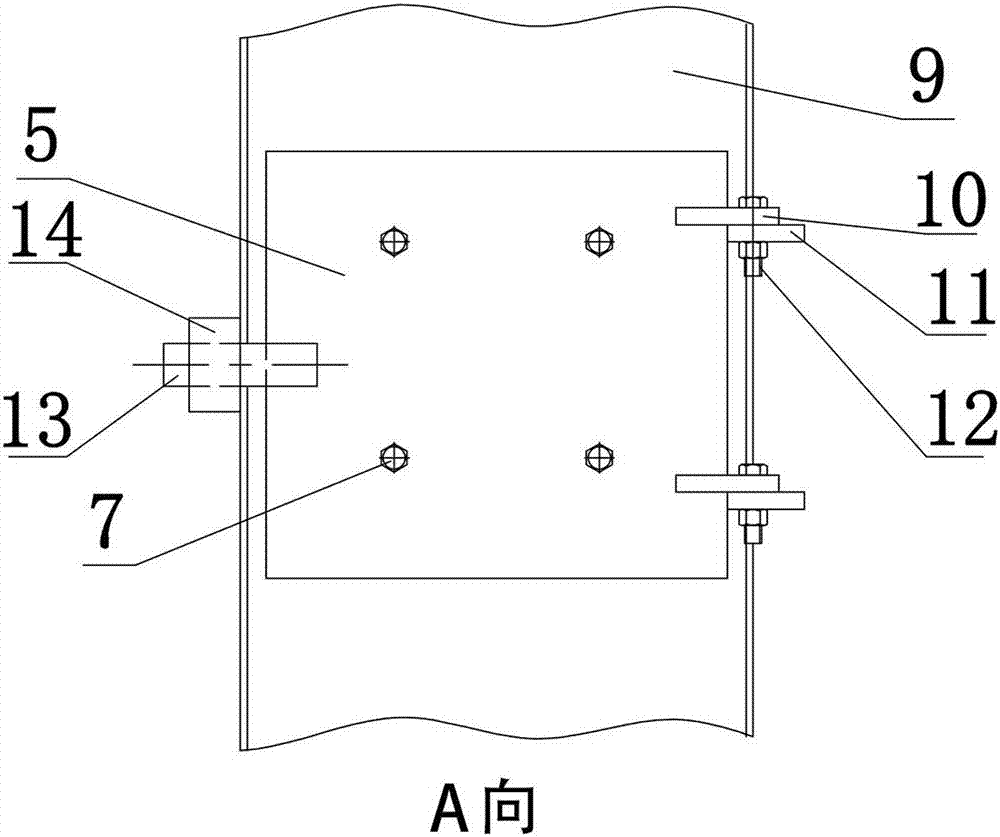

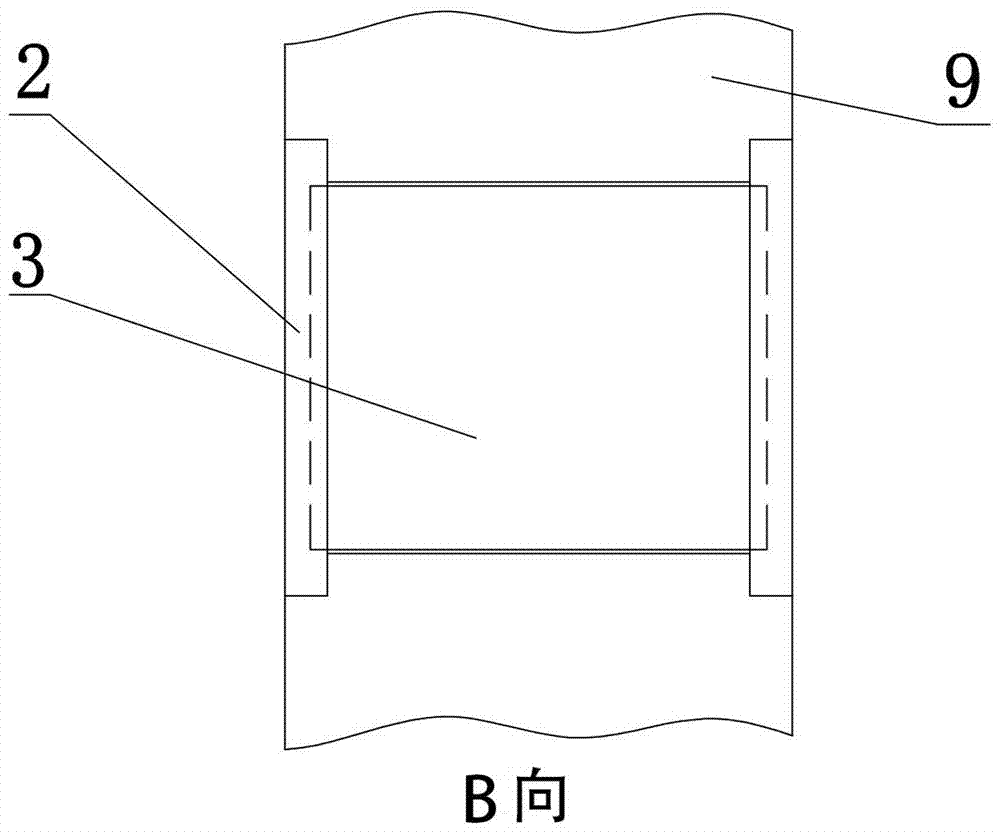

[0020] Such as figure 1 , 2 , 3, the valve-type quick-change lining plate device used on the feeding funnel of the present invention includes the receiving side plate 1 with the feeding funnel 9, and the vulnerable side plate 1 is provided with a The liner replacement port is equipped with two limit strips 2 on the left and right edges of the vulnerable liner replacement port. These two limit strips 2 are connected with the liner revolving door assembly, and the liner rotates The door assembly consists of a revolving door panel 5, two hinges connected to one side of the revolving door panel 5, a door panel switch connected to the other side of the revolving door panel, and fixedly connected to the inner surface of the revolving door panel A group of pallets 6, corresponding to a group of lining board hanging boards 4 hung on this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com