Organic phase extraction and rare-earth separation process

An organic extractant and organic phase technology, which is applied in the field of saponified organic phase circular extraction of rare earth stock solution, can solve problems such as the decline of extraction effect, achieve the effects of increasing production capacity, improving product quality, and ensuring circular production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

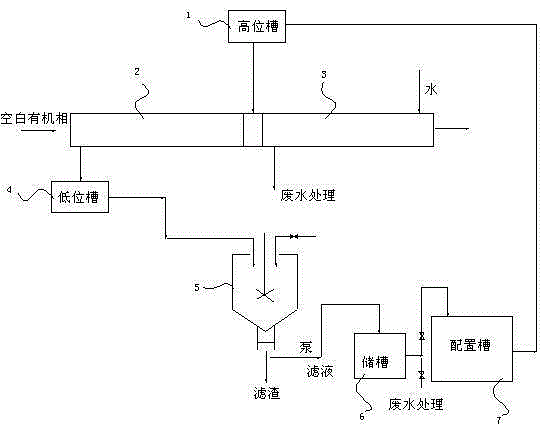

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0017] Organic phase extraction rare earth separation process, taking P507 organic extractant as an example, after the saponification of the organic extractant, the rare earth ions in the rare earth stock solution are extracted, and the organic phase containing rare earth elements is washed and back-extracted with inorganic acid (hydrochloric acid) to make the organic The rare earth elements in the phase are separated into the water phase, and the obtained blank organic phase needs to undergo a pretreatment process before cyclic saponification. Washing solution) Back-extract more than 90% of uranium and thorium in the blank organic phase, and wash with water to reduce the overall concentration of free ions in the organic phase.

[0018] As shown in Figure 1, the specific pretreatment equipment includes a continuous 10-stage tank as a mixing ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com