A kind of oriented carbon nanotube-alumina hybrid fiber and preparation method thereof

A carbon nanotube fiber and oriented carbon nanotube technology, which is applied in the field of carbon nanotube-alumina hybrid fiber and its preparation, can solve the difficulty of controllable coating thickness and repeatable preparation, and cannot achieve uniform coating of alumina , difficult deposits, etc., to ensure uniformity and consistency, achieve uniform coating, and achieve the effect of high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

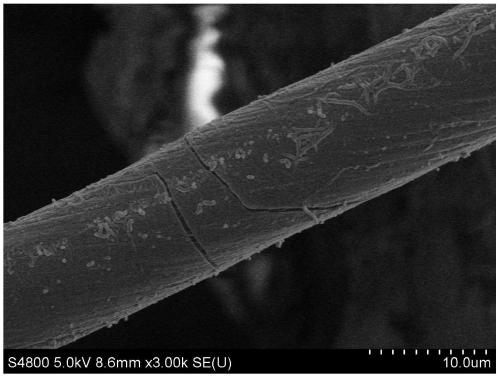

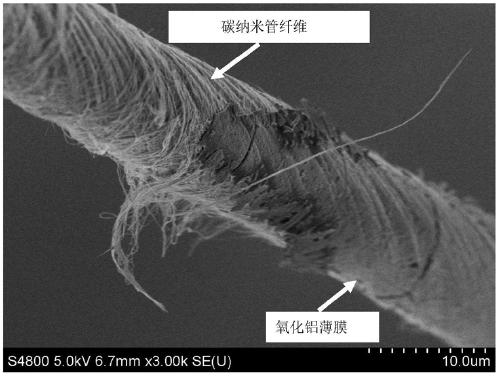

[0035] a kind of like figure 1 As shown in the oriented carbon nanotube-alumina hybrid fiber of the present invention, the carbon nanotube-alumina hybrid fiber comprises carbon nanotube fibers and an aluminum oxide film uniformly coated on the surface of the carbon nanotube fibers. The samples after chemical fiber tensile fracture were subjected to scanning electron microscopy (such as image 3 Shown) found that the aligned carbon nanotube-alumina hybrid fiber has a core-shell orientation structure.

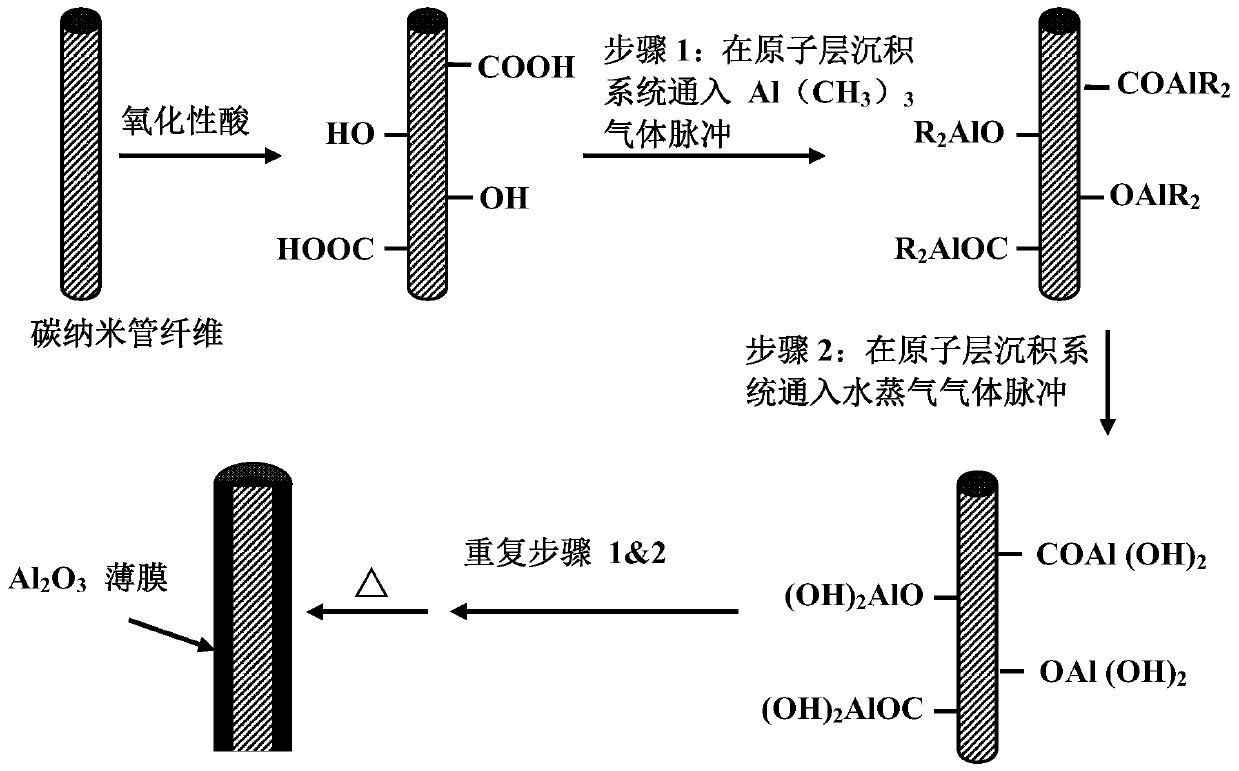

[0036] like figure 2 As shown, the preparation steps of the above-mentioned oriented carbon nanotube-alumina hybrid fiber in this embodiment include:

[0037] (1) Place one or more pure carbon nanotube fibers in a mixture of 25mol / L dilute HNO 3 Soak in the polytetrafluoroethylene container of solution for 12h at normal temperature, to realize the hydroxylation of carbon nanotube fibers;

[0038] (2) Wash the carbon nanotube fibers after step (1) with distilled water until t...

Embodiment 2

[0049] An oriented carbon nanotube-alumina hybrid fiber of the present invention, the carbon nanotube-alumina hybrid fiber comprises carbon nanotube fibers and an aluminum oxide film uniformly coated on the surface of the carbon nanotube fibers. The samples after chemical fiber tensile fracture were subjected to scanning electron microscopy (such as Figure 4 Shown) found that the aligned carbon nanotube-alumina hybrid fiber has a core-shell orientation structure.

[0050] like figure 2 As shown, the preparation steps of the above-mentioned oriented carbon nanotube-alumina hybrid fiber in this embodiment include:

[0051] (1) Place one or more pure carbon nanotube fibers in a solution containing mixed acid (concentrated HNO with a volume ratio of 1:3 3 and concentrated H 2 SO 4 Mixed solution) in the polytetrafluoroethylene container of normal temperature soaking 4h, to realize the hydroxylation of carbon nanotube fiber;

[0052] (2) Wash the carbon nanotube fibers after...

Embodiment 3

[0063] An oriented carbon nanotube-alumina hybrid fiber of the present invention, the carbon nanotube-alumina hybrid fiber comprises carbon nanotube fibers and an aluminum oxide film uniformly coated on the surface of the carbon nanotube fibers. The samples after chemical fiber tensile fracture were subjected to scanning electron microscopy (such as Figure 5 Shown) found that the aligned carbon nanotube-alumina hybrid fiber has a core-shell orientation structure.

[0064] like figure 2 As shown, the preparation steps of the above-mentioned oriented carbon nanotube-alumina hybrid fiber in this embodiment include:

[0065] (1) Place one or more pure carbon nanotube fibers in a mixture of 20mol / L dilute HNO 3 Soak in the polytetrafluoroethylene container of solution for 12h at normal temperature, to realize the hydroxylation of carbon nanotube fibers;

[0066] (2) Wash the carbon nanotube fibers after step (1) with distilled water until the pH is neutral, and dry them in vac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com