Method for stopping water in karstic tubular fractures in flowing water condition through loofah sponges and grouting

A loofah pulp and karst technology, which is applied in the field of hydrodynamic karst tubular fissure loofah pulp grouting and water stop, can solve the problems of lack of effective, convenient and economical methods, etc., and achieve the effect of abundant yield, obvious effect and good cementation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

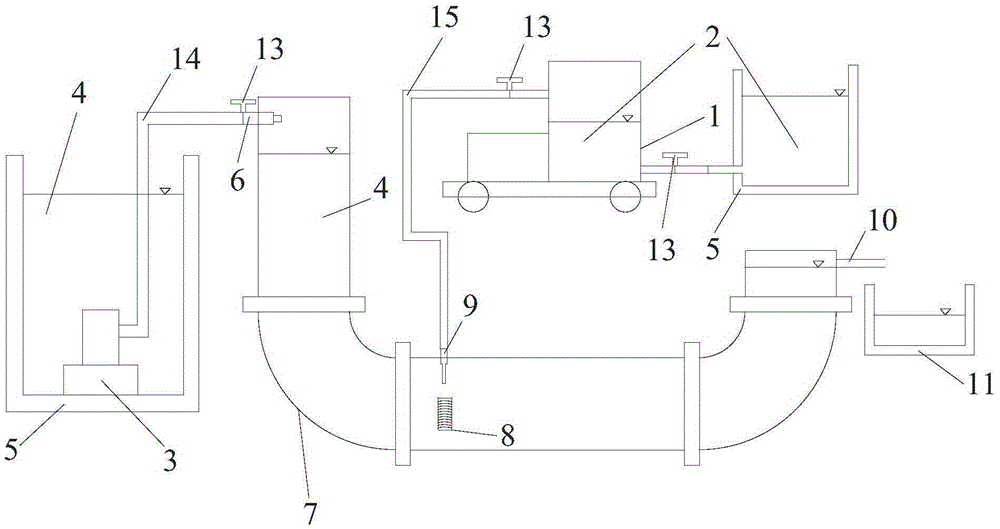

[0025] The present invention will be described in detail below with reference to the drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention, and a detailed implementation mode and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

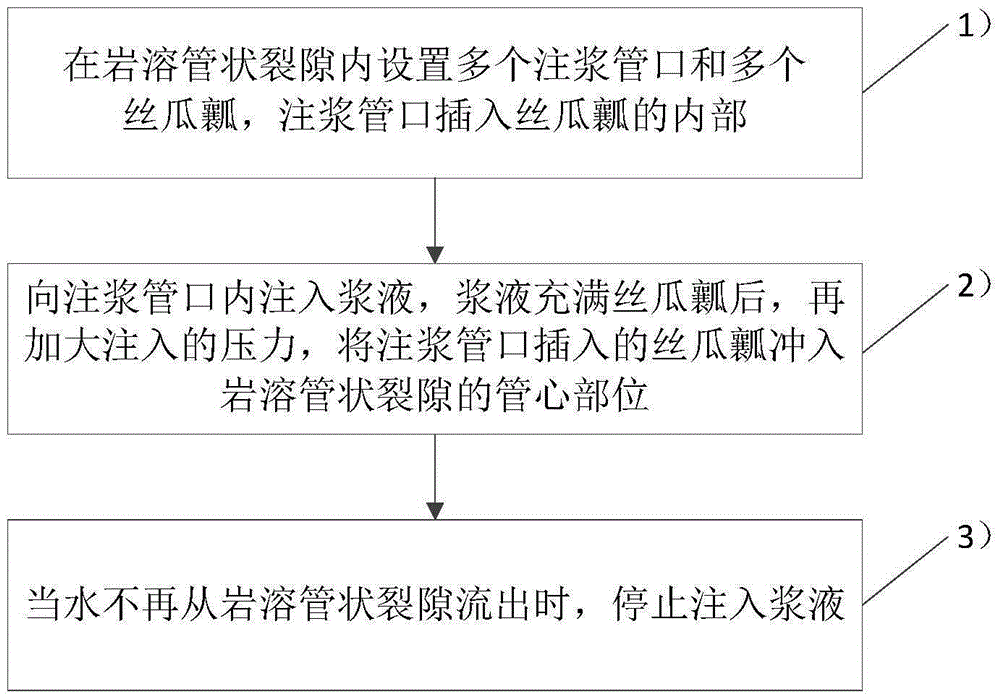

[0026] Such as figure 1 As shown, a method for grouting and stopping water from loofah flesh in a tubular fissure in a dynamic water karst karst area includes the following steps:

[0027] 1) A plurality of grouting nozzles 9 and a plurality of loofah flesh 8 are set on the pipe wall of a karst tubular fissure under dynamic water conditions, and the loofah flesh 8 is moistened with water 4, and then the grouting nozzle 9 is inserted into the loofah flesh 8 internal;

[0028] 2) The grouting pump 1 injects the cement slurry 2 into the grouting nozzle 9 through the grouting pipe 15. After the cement ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com