Maintenance method for building interior wall surface mildewing

An in-building and internal technology, applied in the direction of building maintenance, construction, building structure, etc., can solve the problems of mildew, mildew on the interior wall surface, water leakage on the interior wall surface, etc., and achieves simple construction, simple method and low investment cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

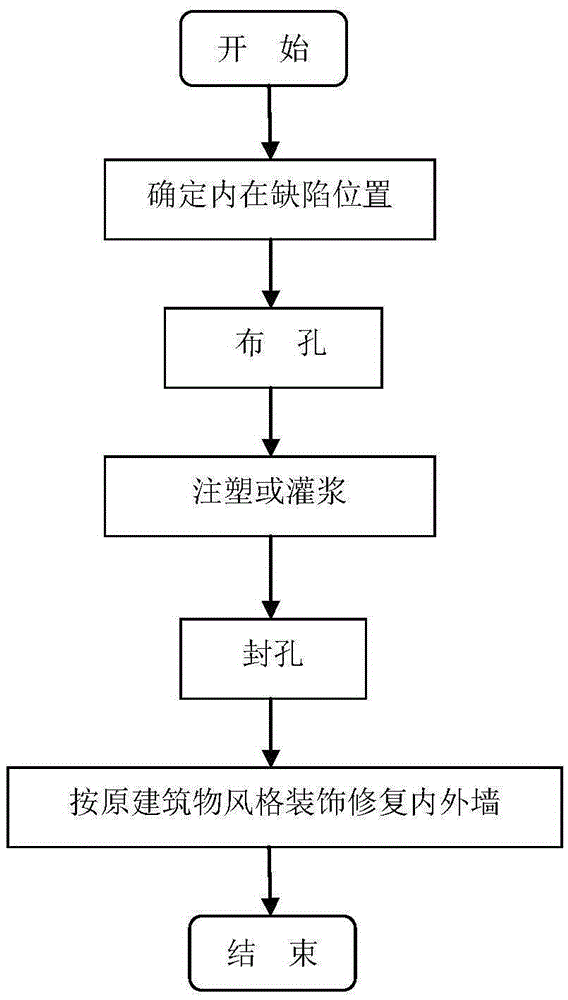

[0030] To deal with mildew at the corner of the inner wall 900x800mm, the maintenance steps are as follows:

[0031] 1) Within the area of 1000x1000mm on the exterior wall corresponding to mildew and its surroundings, hit the wall with a hand hammer to hear the echo of "Weng Weng" in many places. It is preliminarily judged that there may be internal voids or pine looseness. Use a hand hammer to pierce a steel needle into the wall to investigate the depth of the cavity or crack at the deepest point of 200mm, and determine the defect range to be 1000x1000mm around the mildew.

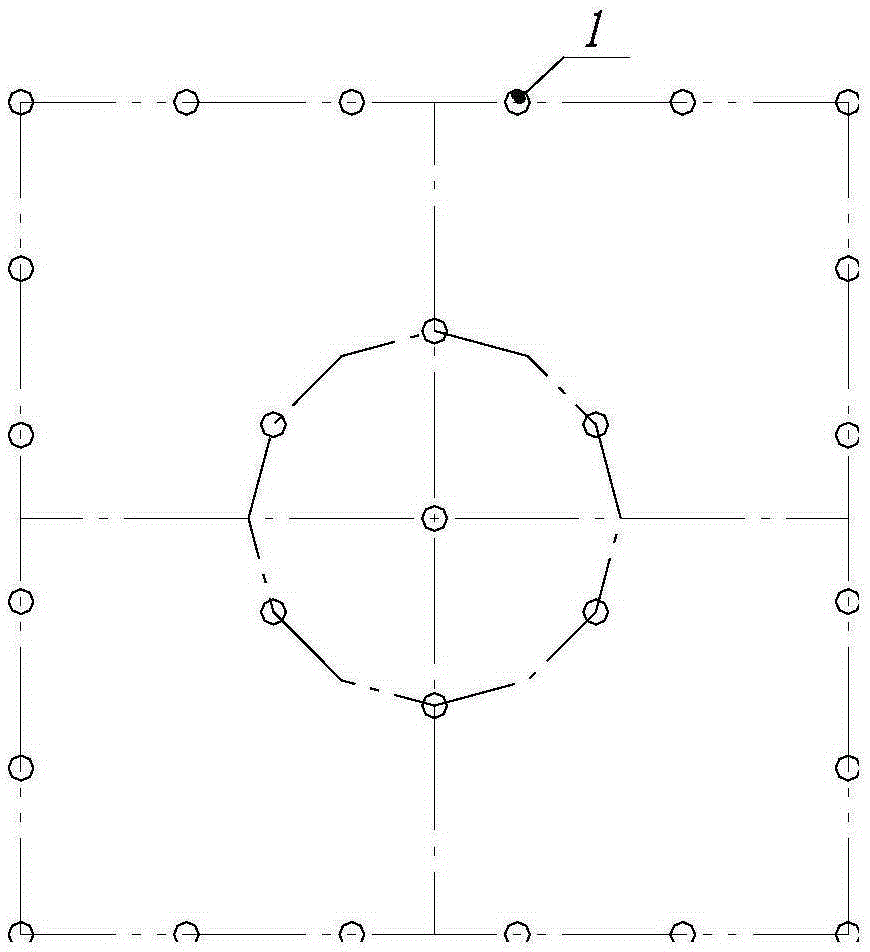

[0032] 2) see figure 2 , on the outer wall, use an electric drill to drill 20 injection molding holes from the periphery of the determined defect range of 1000x1000mm, the hole distance is 200mm, the hole diameter is 30mm, and the maximum depth is 210mm, which is less than 1 / 2 of the wall thickness (the measured wall thickness is 450mm). Effectively frame the defect within the processing range; punch ...

Embodiment 2

[0037] The range of mildew at the treatment window is 800x100mm, and the maintenance steps are as follows:

[0038] 1) In the 900x120mm range of the outer wall corresponding to mildew and its surroundings, no obvious "Weng Weng" echo can be heard when hitting the wall with a hand hammer using the percussion method. It is preliminarily judged that there may be internal looseness or cracks. Use the hand hammer to pierce the steel needle into the deepest hole or crack of the wall to check the depth of 180mm, and determine the defect range to be 900x120mm around the mildew.

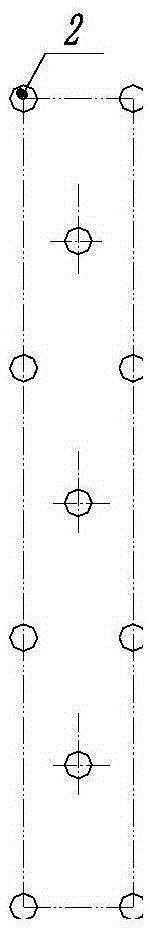

[0039] 2) see image 3 , on the outer wall, use an electric drill to drill 8 injection molding holes from the periphery of the determined defect range of 900x120mm, the hole distance in the length direction is 300mm, the hole distance in the width direction is 120mm, the hole diameter is 30mm, and the maximum depth is 200mm, which is less than 1 / 2 of the thickness of the wall (measured The thickness of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com