A prefabricated integral toilet and its construction method

A toilet, prefabricated technology, applied in the direction of building structure, building, building type, etc., can solve the problems of poor sound insulation effect, inability to modify sanitary ware and facilities, low fire performance, etc., to reduce environmental pollution and noise emissions, excellent fire prevention. Performance and sound insulation performance, the effect of easy installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

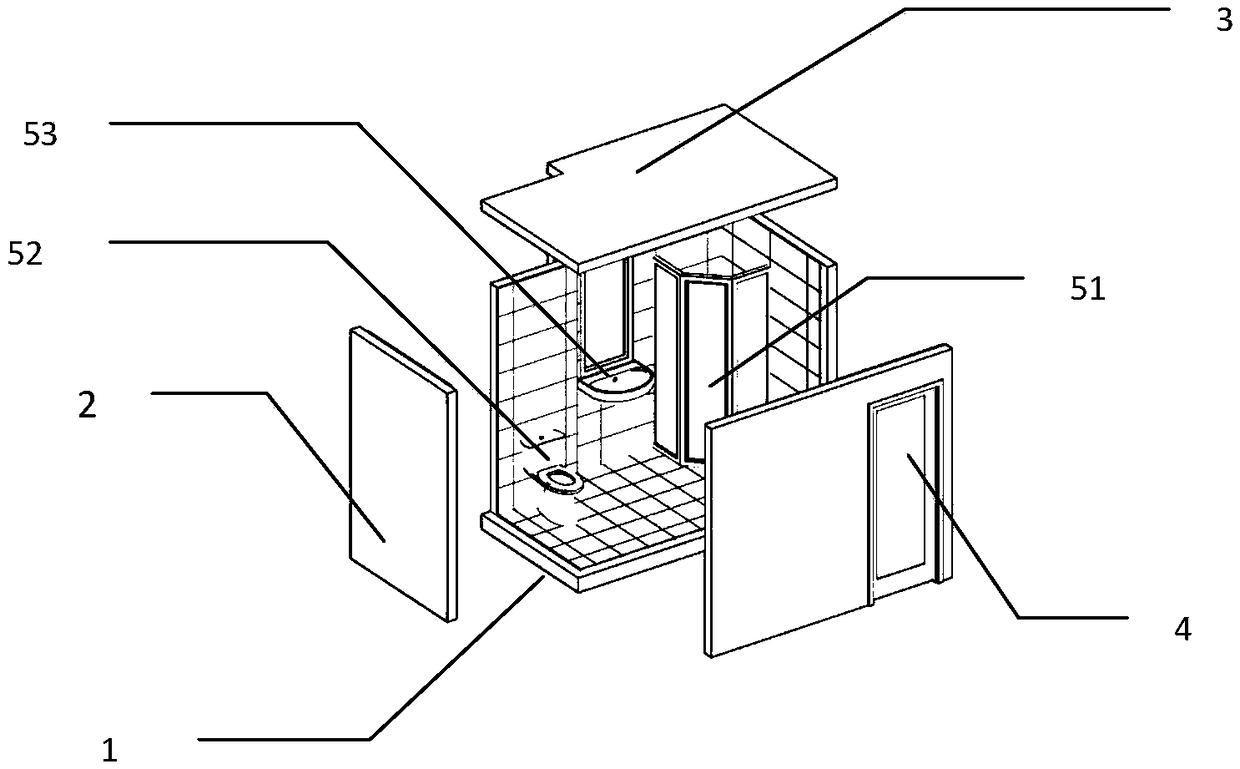

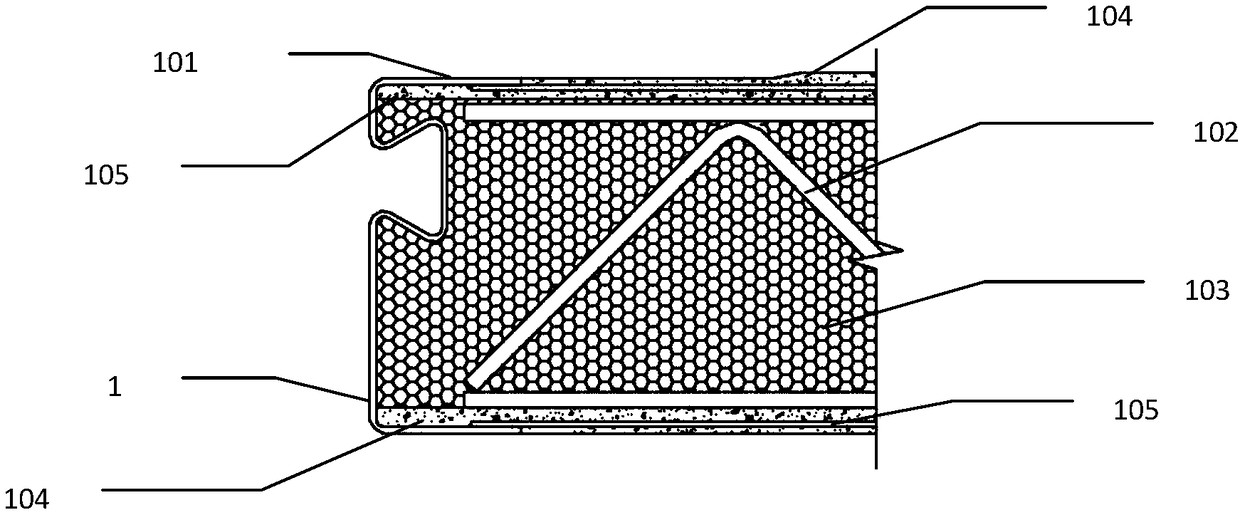

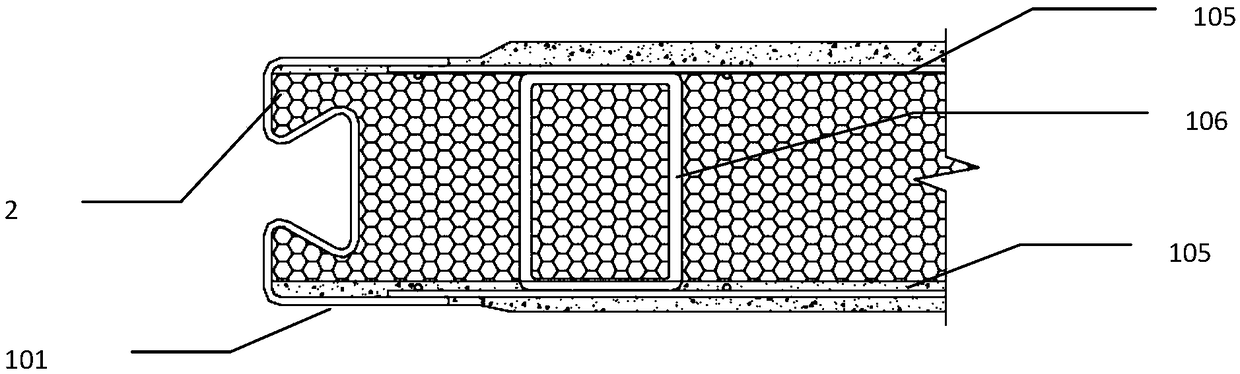

[0075] Such as Figure 1 to Figure 6 As shown, the prefabricated integrated toilet of the present invention mainly includes: foamed cement composite floor 1, foamed cement composite wallboard 2, foamed cement composite top board 3 and bathroom equipment: bathing equipment 51, toilet 52, sink 53.

[0076] The foamed cement composite bottom plate 1, the foamed cement composite wallboard 2, and the foamed cement composite top plate 3 are respectively provided with dovetail groove type steel frame side ribs 6; the described dovetail groove type steel frame side ribs 6 , consisting of the upper and lower flanges and the dovetail rib groove 61; and the embedded component wedge block 7 is provided in the dovetail groove rib groove 61; and the bolt is provided in the wedge block 7 74 fit holes 70 and slots 71 for placing nuts 73 .

[0077] The connection between the foamed cement composite base plate 1 and the described foamed cement composite wallboard 2 is to pass through the right...

Embodiment 2

[0101] Such as figure 1 , Figure 2-1 to Figure 2-4 , Figure 7-1 , Figure 7-2 , Figure 8 As shown, the prefabricated integrated toilet of the present invention mainly includes: foamed cement composite floor 1, foamed cement composite wallboard 2, foamed cement composite top board 3 and bathroom equipment: bathing equipment 51, toilet 52, sink 53.

[0102] The foamed cement composite bottom plate 1, the foamed cement composite wallboard 2, and the foamed cement composite top plate 3 are respectively provided with dovetail groove type steel frame side ribs 6; the described dovetail groove type steel frame side ribs 6 , consisting of the upper and lower flanges and the dovetail rib groove 61; and the embedded component wedge block 7 is provided in the dovetail groove rib groove 61; and the wedge block 7 is provided with a bolt 74 to cooperate with Threaded hole 72.

[0103] The connection between the foamed cement composite bottom plate 1 and the described foamed cement c...

Embodiment 3

[0120] Such as figure 1 , Figure 2-1 to Figure 2-4 , Figure 9 , Figure 10-1 , Figure 10-2 , Figure 11 , Figure 12-1 , Figure 12-2 As shown, the prefabricated overall toilet of the present invention mainly includes: foamed cement composite bottom plate 1', foamed cement composite wallboard 2 or foamed cement composite wallboard 2', foamed cement composite top board 3' and bathroom equipment: bath Equipment 51, toilet 52, washbasin 53.

[0121] The foamed cement composite bottom plate 1' or the described foamed cement composite top plate 3' is provided with a flat groove type steel frame side rib 9, which is composed of upper and lower flanges and a flat groove 91; and the flange is provided with Hole 70; Be provided with hole 92 at flat groove standing edge place; Be provided with the cavity 93 that is closed by steel plate or section steel in hole 92 flat grooves, so that put into bolt 74 by hole 92.

[0122] The foamed cement composite wallboard 2 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com