A sealing method and structure of a temperature sensor interface

A temperature sensor and interface technology, which is applied in the field of sealing of downhole equipment and instruments in natural gas fields, can solve the problems of poor long-term sealing reliability, inconvenient maintenance and replacement, and easy corrosion of weld seams, so as to prevent thermal expansion and contraction and excessive leakage loss , the effect of rapid temperature sensing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

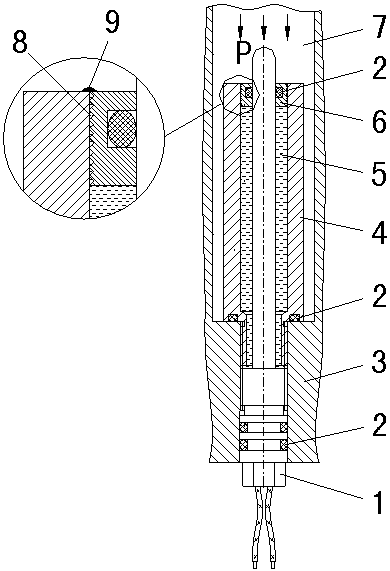

[0021] This example figure 1 As shown, during specific implementation, a temperature-sensing window 7 can be processed on the outer surface of the casing 3 of the downhole instrument, and an interface for installing the temperature sensor 1 can be processed at the bottom of the temperature-sensing window 7, and a threaded hole is processed in the inner hole of the interface. And the light hole, a section of light hole near the inner surface of the housing 3, and a section of threaded hole near the outer surface of the housing, in which the temperature sensor 1 and the liquid storage shell 4 are installed. A discharge sleeve 6 is installed in the inner hole at the top of the liquid storage case 4, and a spiral groove 8 is processed on the outer circle of the discharge sleeve. An interference fit is adopted between the inner hole of the liquid storage shell 4 and the outer circle of the discharge sleeve 6, and the circular seams of the end faces are spot-welded 9 to prevent the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com