A small segmental approach filling mining method for vertical middle and deep hole falling

A technology of approach filling and mining method, which is applied in ground mining, underground mining, special mining, etc. It can solve the problems of large empty side of the mine, high mining cost, and hanging upside down on dangerous rocks, so as to achieve a high degree of safety in the operating environment, The effect of reducing the amount of accurate engineering and leveling and smooth support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

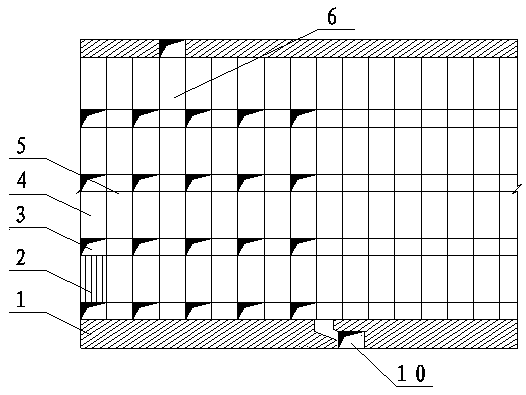

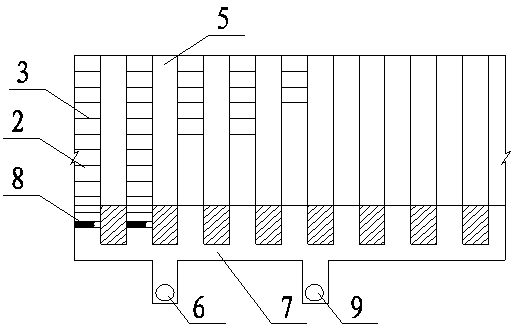

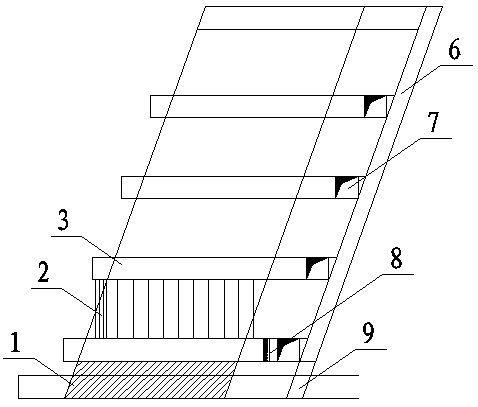

[0031] The construction scheme of the arrangement method for the vertical medium-deep hole small-section approach proposed by the present invention is as follows:

[0032] (1) Stope cutting:

[0033] Both the segmental connecting roadway and the rock drilling approach are located above the bottom pillar of the stope, and the segmental connecting roadway is 5 to 8 meters away from the chassis ore-rock boundary. Slide the mine shaft and the return air filling shaft that runs through the upper middle section of the transport level roadway, and then dig a segmented rock drilling roadway with a relatively large width and height from the vertical ore body of the segmental contact roadway to the upper wall every 3 to 5 meters, and the segmented rock drilling roadway During excavation, smooth blasting should be used for the surrounding holes, and the unstable area in the roof of the upper rock drilling roadway needs to be supported by anchor nets.

[0034] (2) Rock drilling and blast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com