Axial flow turbine with small blade structure

A small blade, axial flow technology, applied in the direction of blade support elements, engine elements, machines/engines, etc., can solve the problems of large separation scale, increased load, and reduced turbine performance, to suppress lateral movement, reduce Effect of load, transverse pressure gradient reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The axial flow turbine with small blade structure of the present invention will be described in detail below with reference to the accompanying drawings.

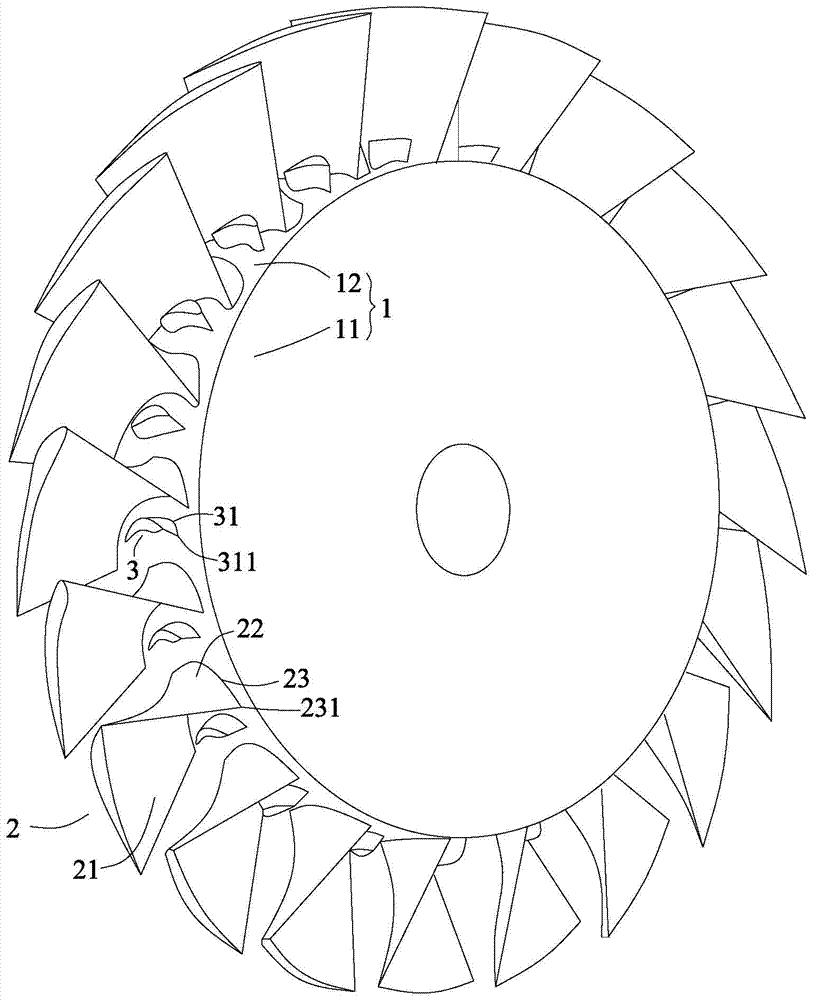

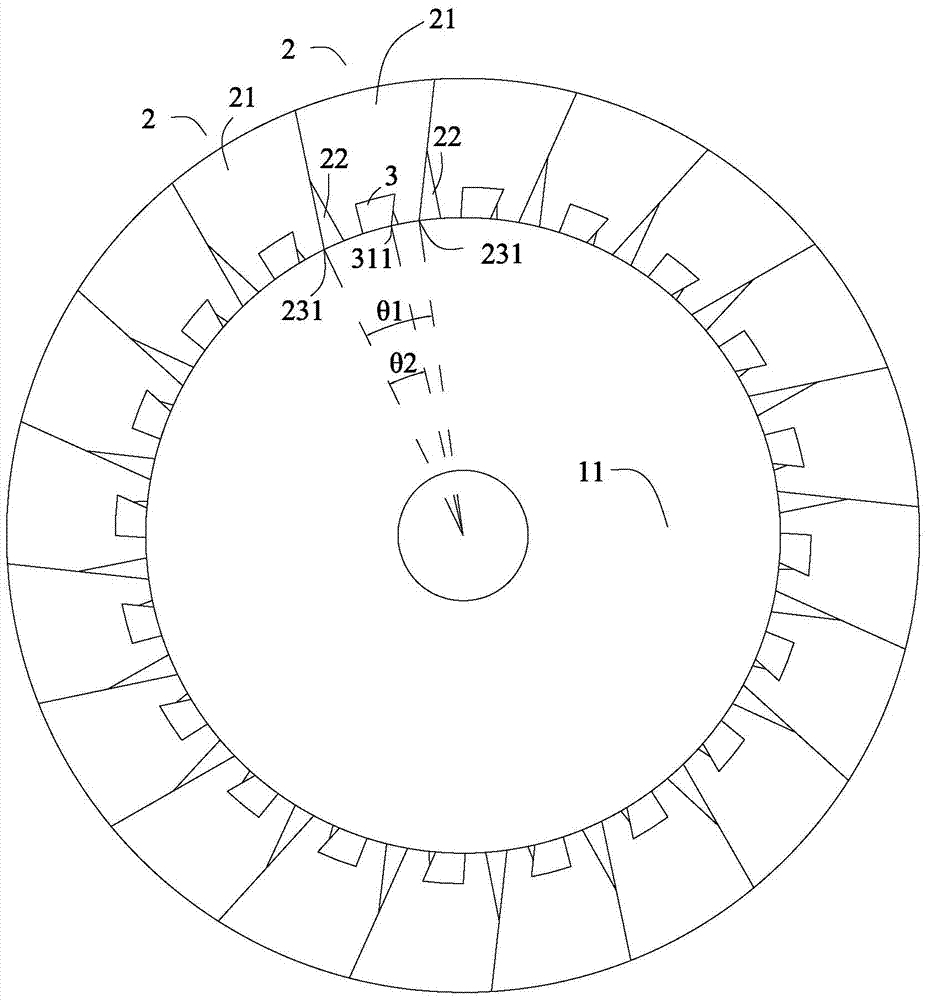

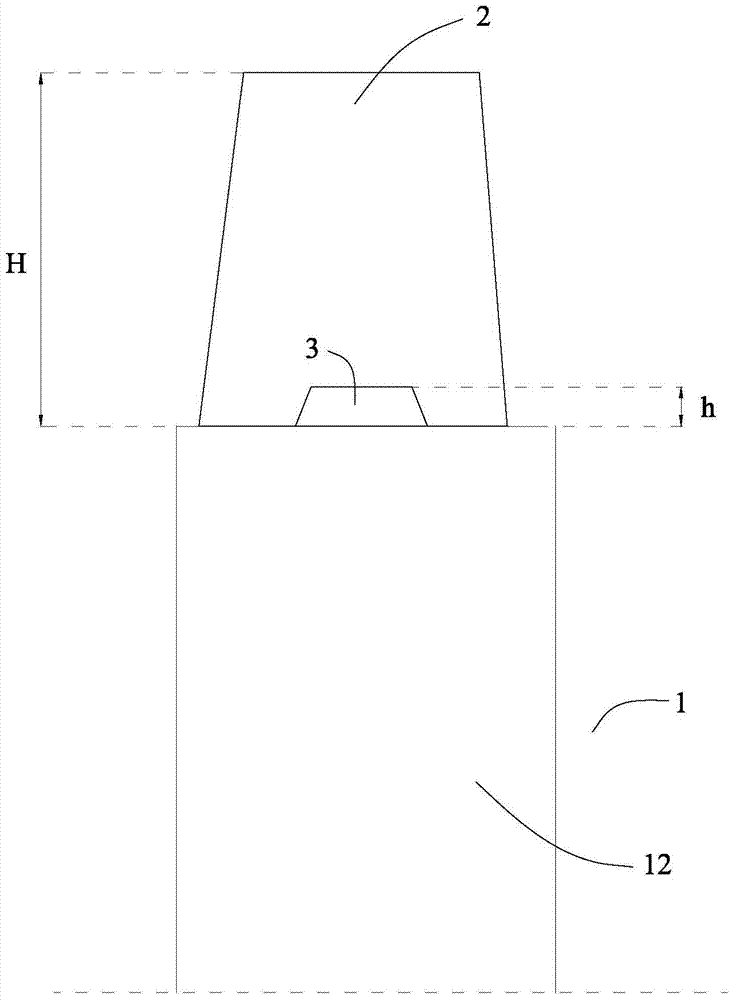

[0027] refer to Figure 1 to Figure 4 , according to the present invention, the axial flow turbine with small blade structure includes a hub 1 , a plurality of main blades 2 and a plurality of small blades 3 .

[0028] The hub 1 is provided with a front end face 11 and a peripheral face 12 .

[0029] The plurality of main blades 2 are evenly arranged on the circumferential surface 12 of the hub 1, and each main blade 2 has: a pressure surface 21, opposite to the direction of the incoming airflow; a suction surface 22, opposite to the pressure surface 21; and a main blade The connection surface 23 is a cross section connecting the main blade 2 and the circumferential surface 12 of the hub 1 , and is provided with a first leading edge 231 close to the front end surface 11 of the hub 1 .

[0030] The plurality of smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com