Radiator dust cover

A technology of radiator and dust cover, applied in the direction of machine/engine, engine components, engine cooling, etc., can solve the problem of affecting the life of the engine and the performance of the harvester, reducing the air intake area of the radiator dust cover, and the overheating of the engine. and other problems, to achieve the effect of improving the working performance of the whole machine, reducing the time for manual cleaning of impurities, and reducing the number of blockages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

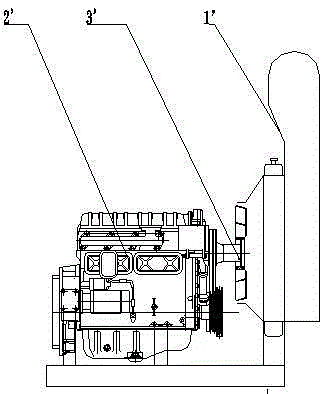

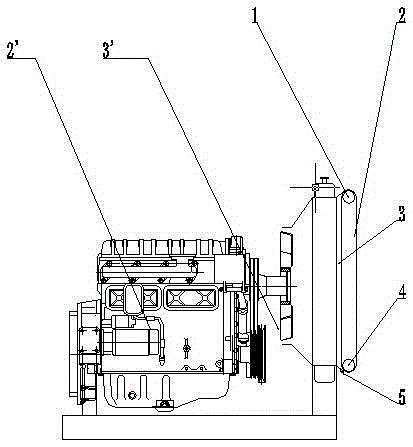

[0021] Examples, as attached figure 2 And attached image 3 Shown, radiator dust cover comprises the soft mesh belt 2 that is arranged on radiator 1 ' side that can rotate cyclically.

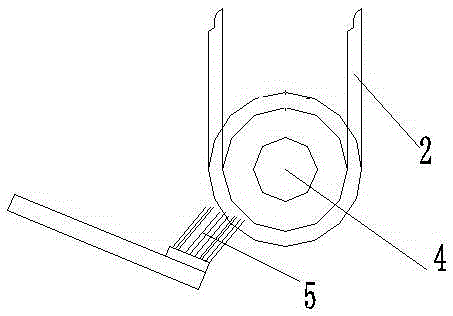

[0022] It also includes a drive shaft 1 and a driven shaft 4, and the soft mesh belt 2 rotates in a reciprocating cycle around the drive shaft 1 and the driven shaft 4.

[0023] A brush 5 is also included, and the brush 5 is arranged at a position close to the driving shaft 1 and the driven shaft 4 .

[0024] The bristle of hairbrush 5 contacts with soft mesh belt 2.

[0025] The radiator 1' is fixedly provided with a sealing rubber ring 3, and the sealing rubber ring 3 is arranged between the soft mesh belt 2 and the radiator 1'.

[0026] The sealing rubber ring 3 is arranged on the left and right ends of the soft mesh belt 2, and the hairbrush 5 is arranged on the upper and lower ends of the soft mesh belt 2, and the sealing rubber ring 3 is connected with the brush 5 and the soft mesh be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com