Integrated small embedded hydraulic oil source

A hydraulic oil source and embedded technology, which is applied in the direction of oil supply tank devices, fluid pressure actuators, servo motor components, etc., can solve the problems of large volume of hydraulic oil sources, narrow installation space, and strict weight requirements, and achieve Short pressure build-up time, small size and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

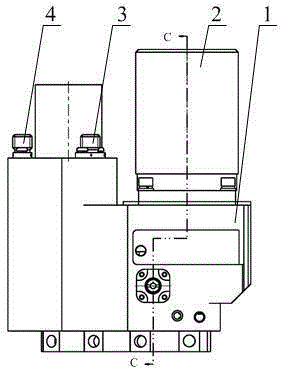

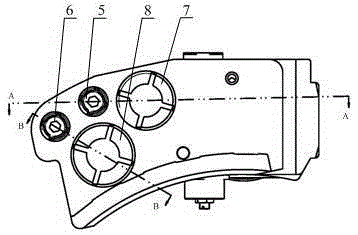

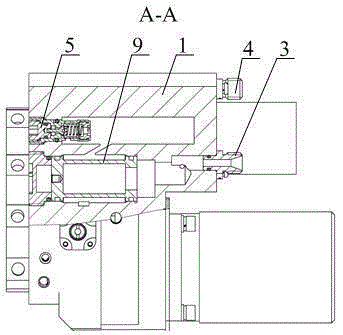

[0016] An integrated and miniaturized embedded hydraulic oil source, including: a channel body 1, a motor 2, a high-pressure pipe joint 3, a low-pressure pipe joint 4, an oil filter cover 7, an oil tank cover 8, an oil filter 9 and a constant pressure variable pump core 14 , also includes: low-pressure fuel injection valve 5, high-pressure fuel injection valve 6, pressurized oil tank 10 and retaining ring 11.

[0017] The channel body 1 is an L-shaped metal body with a radian. The upper surface of the channel body 1 has a booster piston installation hole, a hydraulic pump installation groove, a high-pressure oil outlet channel and a low-pressure oil return channel. The lower surface of the channel body 1 has a high-pressure oil injection hole, a low-pressure oil injection hole, an oil filter hole and an oil tank hole. The bottom surface of the hydraulic pump mounting groove has a hydraulic pump oil outlet channel and a hydraulic pump oil suction channel.

[0018] The pump cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com