Pipe joint sealing equipment

A technology for sealing equipment and pipes, applied in the direction of pipe connection arrangement, mechanical equipment, pipe/pipe joint/pipe fittings, etc., can solve the problems of inconvenient operation and high cost, and achieve the effect of easy portability, convenient operation, and enhanced strength and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

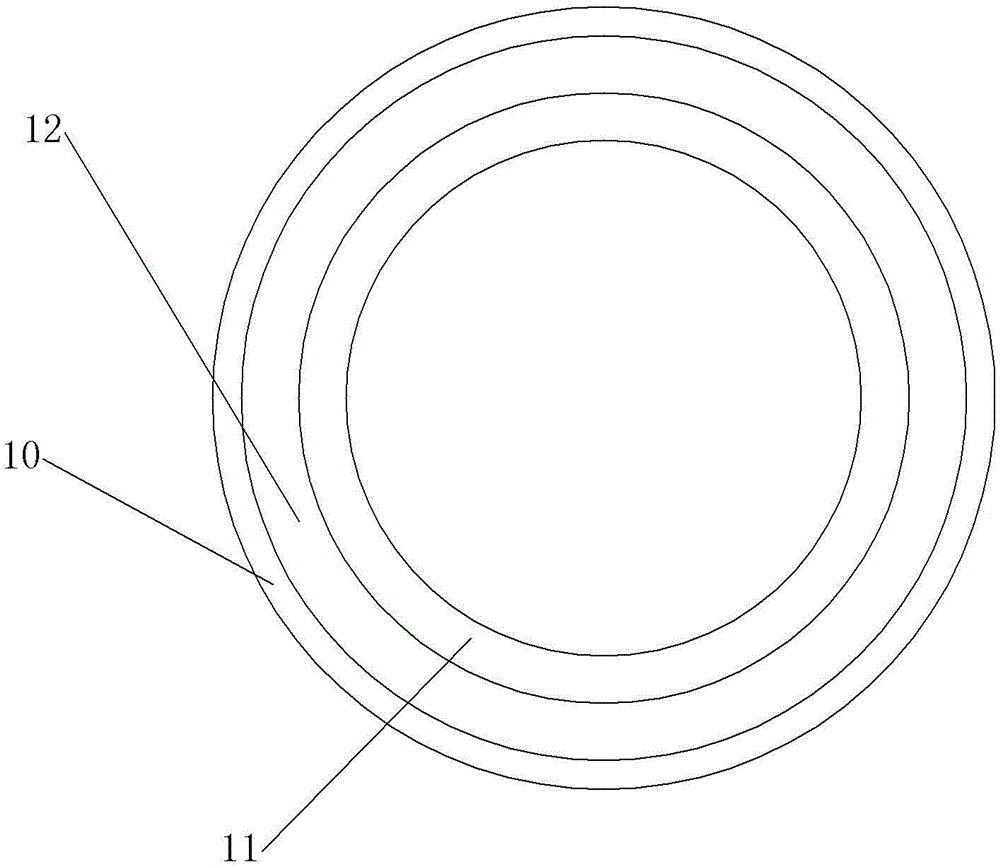

[0020] Embodiment 1 is basically as attached figure 1 , figure 2 Shown: The pipe joint sealing equipment includes a small air pump, an outer fixing ring, an inner fixing ring and an air bag, and also includes a plug storage box, which is detachably connected to the small air pump; the outer diameter of the inner fixing ring is smaller than that of the pipe Inner diameter, the inner diameter of the outer fixing ring is larger than the outer diameter of the pipe, the airbag is circular and consists of two pieces, the outer wall of the airbag is provided with a strong adhesive layer and bonded between the inner fixing ring and the outer fixing ring, the thickness of the strong adhesive layer is 1-3cm ; Through practice, the strong adhesive layer within this range has the best effect when sealing the pipe joints. There are air holes on the outer fixing ring or inner fixing ring, and plugs are set on the air holes, and the plug storage box is fixed on the small air pump by Velcro...

Embodiment 2

[0025] The only difference from Embodiment 1 is that the plug storage box is embedded in the handle of the small air pump; it is convenient to carry and saves space.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com