Multi-spiral cavity biofuel heating furnace

A biofuel and heating stove technology, applied in the field of multi-spiral chamber biofuel heating stoves, can solve the problems of unsmooth airflow, aggravation of environmental pollution, and inability to utilize straw heat energy, and achieve smooth airflow and high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

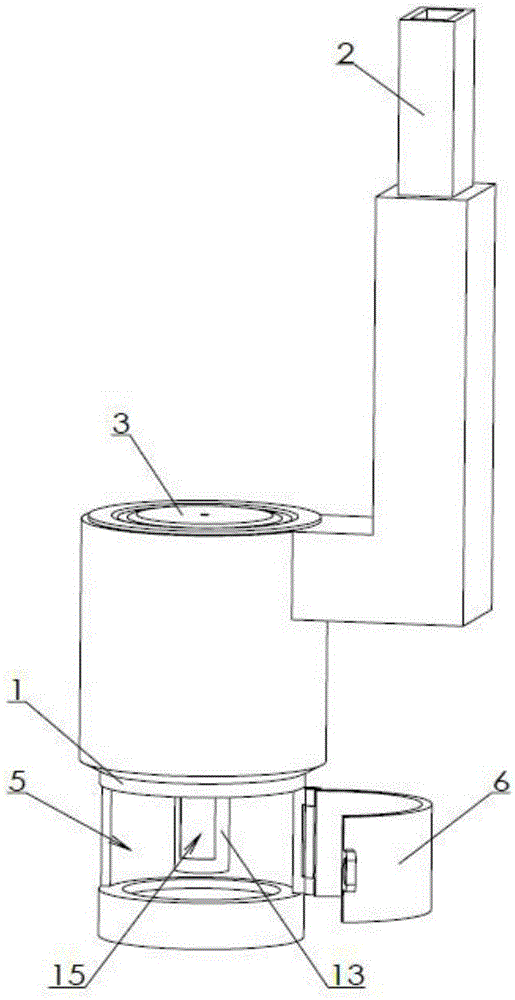

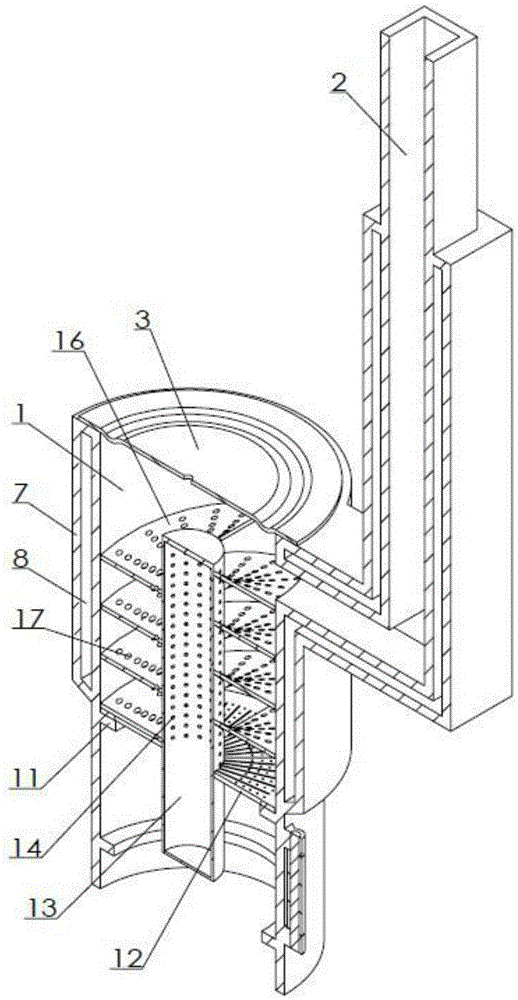

[0012] Examples of the present invention figure 1 , 2 As shown, the multi-spiral chamber biofuel heating furnace is provided with a furnace chamber 1 and a smoke exhaust pipe 2; the furnace chamber is a cylindrical combustion chamber, the upper opening is provided with a furnace cover 3, and the furnace chamber wall is connected to the The smoke exhaust pipe connected internally, the inner wall of the furnace cavity is provided with an opening 5 on the side wall of the furnace cavity close to the lower opening, and the opening is provided with an opening door 6, and an outer wall 7 is connected to the outside of the upper furnace cavity side wall of the opening and the smoke exhaust pipe wall and forms a water Accommodating chamber 8, the lower part of the water accommodating chamber is connected with a water inlet pipe, and the upper part of the water accommodating chamber is connected with a water outlet pipe, which is used to connect the water heating radiator. The inner wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com