Integrated optical path chip used for optical current sensor and optical current sensor thereof

A current sensor, integrated optical circuit technology, applied in the measurement of current/voltage, optics, optical components, etc., can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

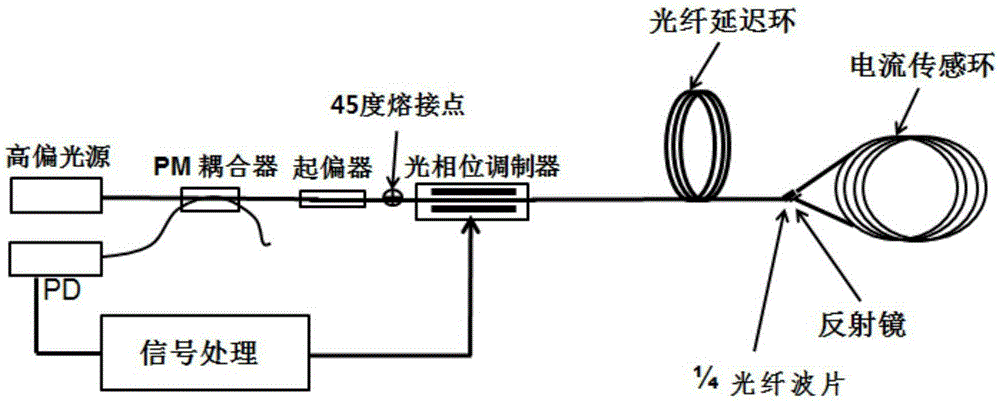

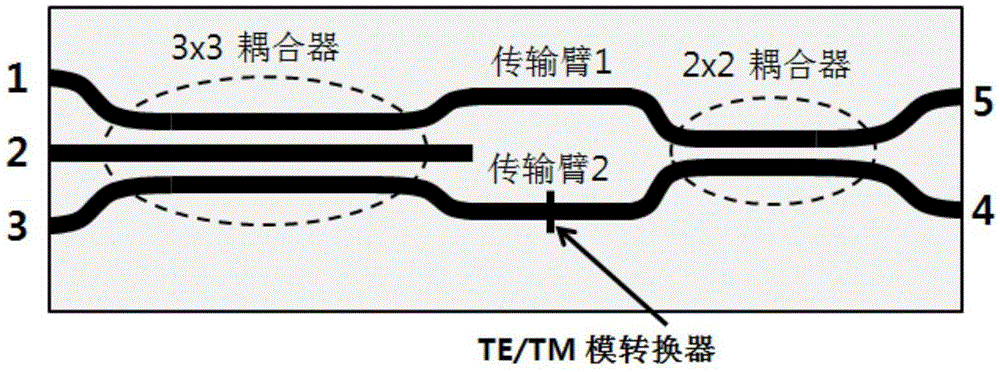

[0021] Example 1, such as Figure 5 As shown, an optical current sensor with an integrated optical circuit chip includes a light source, a photodetector (PD1 and PD2 in the figure), a signal processor, an integrated optical circuit chip, a 1 / 4 optical fiber wave plate, and a current sensing ring; The first port of the integrated optical circuit chip is connected to the signal processor through a photodetector (photodetector PD1 in the figure), and the third port of the integrated optical circuit chip is connected to the signal processor through another photodetector (photodetector PD1 in the figure). PD2) is connected to the signal processor, the second port of the integrated optical circuit chip is connected to the light source, the fourth port of the integrated optical circuit chip is vacant, and the fifth port of the integrated optical circuit chip is connected to the One end of the current sensing ring is provided, and the other end of the current sensing ring is provided ...

Embodiment 2

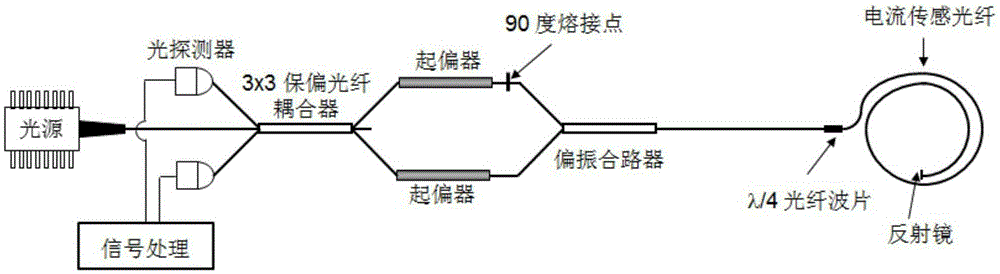

[0024] Embodiment 2, because in many applications, multiple optical current sensors or multiple redundant use are required at one current measurement point. In order to save space and improve efficiency, when cutting the chip, we can integrate multiple optical current sensor device units on the same chip according to requirements, which can also greatly reduce the volume of the current sensor array. As an example, such as Figure 6 As shown, it is a structure with 3 current sensors. in, Figure 6 The 3-way current sensor in the 3-way current sensor uses an integrated optical circuit chip such as Figure 4 As shown, the integrated optical circuit chip for the 3-way current sensor includes three integrated devices required by the integrated optical circuit chip in Embodiment 1, and its installation process is the same as that of the single integrated chip unit in Embodiment 1. For brevity, Figure 6 The optical circuit port of the integrated optical circuit chip for the 3-wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com