Hydroxy-terminated polybutadiene propellant thermal safety evaluation model based on multi-scale simulation modeling

A hydroxybutyl propellant and evaluation model technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as multi-scale models that have not yet been discovered, and achieve easy decomposition and combination, easy implementation, and simple implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following will take the BOH solid propellant under a certain formula as an example to introduce the establishment method of the multi-scale thermal safety model.

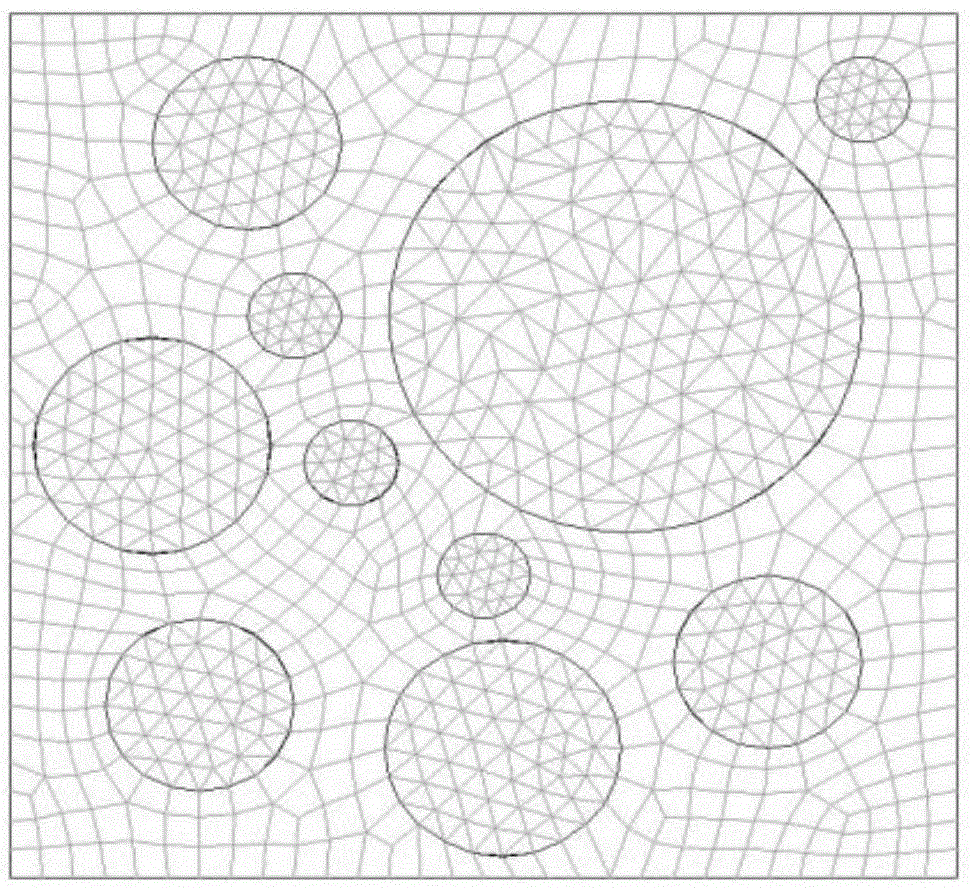

[0048] Step 1: Establish a mesoscopic calculation model of hydroxybutylene propellant

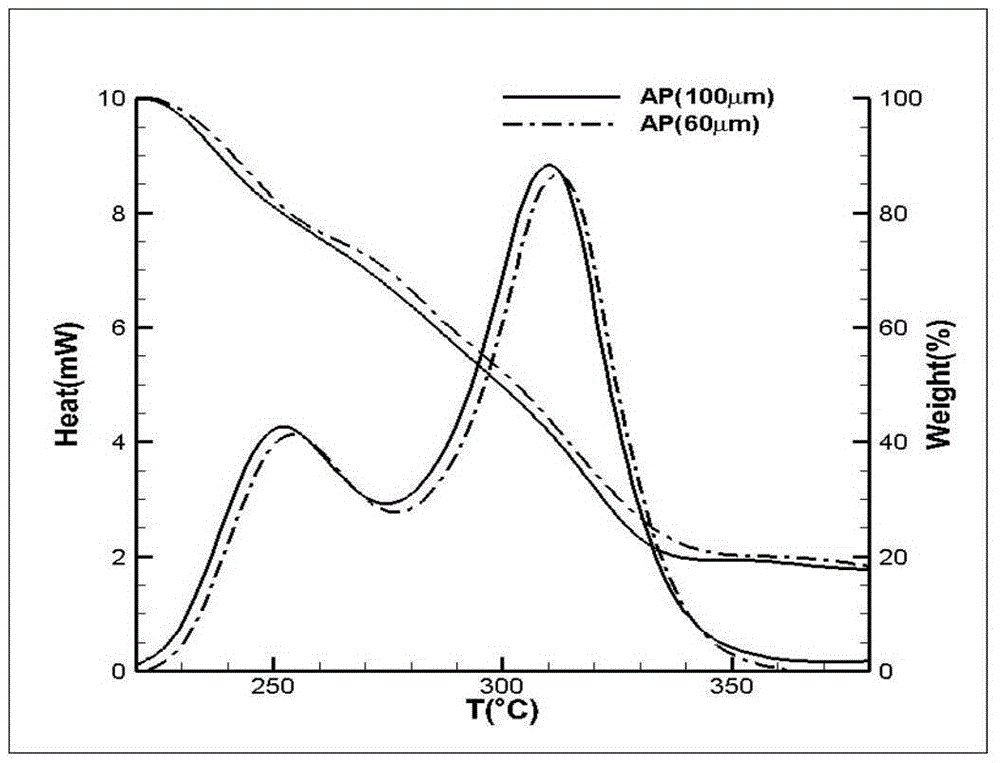

[0049] Step 1.1 Establish the chemical reaction model of oxidant AP particles

[0050] The thermal decomposition process of AP is simplified to a three-step four-component chain chemical reaction model (1) description.

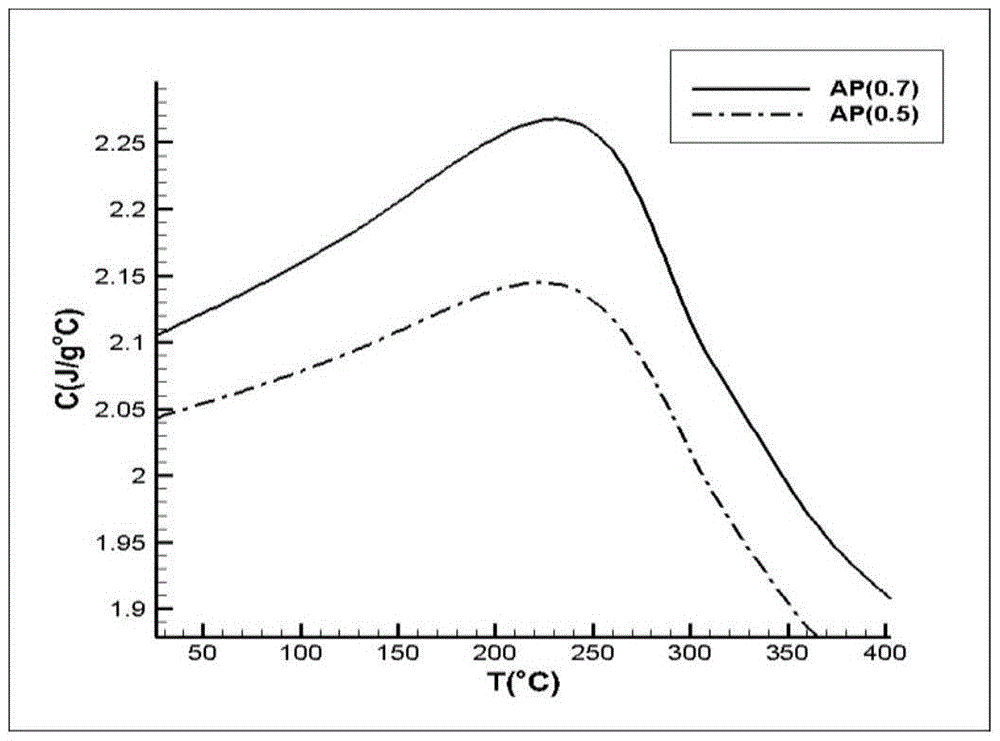

[0051] Since AP will form a large number of voids during the low-temperature decomposition process, which will affect the low-temperature decomposition process of AP, the reaction mechanism function needs to be added to the Arrhenius equation for the second step of the chemical reaction of AP. Related parameters can be obtained by DSC method.

[0052] The established parameters are as follows.

[0053] Table 1AP reaction kinetic parameters and mechanism function

[0054] stage

activati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com