Image acquisition encoding system and method for virtual assembly of steel box girder

An image acquisition and virtual assembly technology, applied in the field of detection and identification, can solve the problems of inability to guarantee the accuracy and quality of splicing, high labor intensity, time-consuming and laborious, etc., to reduce labor intensity and waste of resources, less personnel, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawings and examples of implementation.

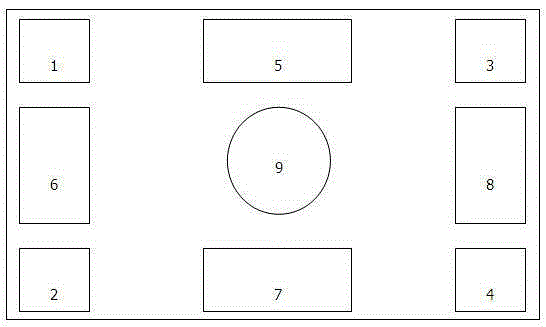

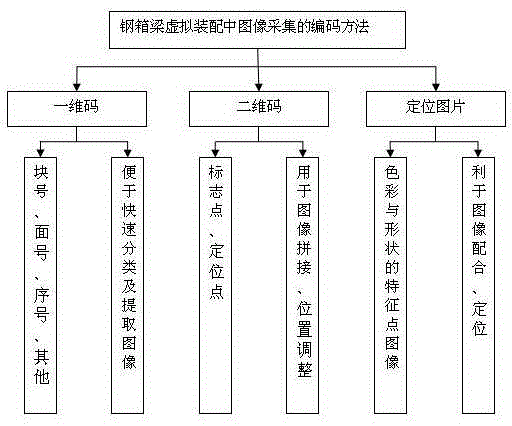

[0036] like figure 1 , figure 2 Shown: a coding method using the image acquisition in the virtual assembly of the steel box girder above, including: one-dimensional code, two-dimensional code (1, 2, 3, 4), and positioning picture (9). Among them, the one-dimensional codes are distributed in the upper, left, lower, and right directions of the collected steel box girder mating surface, each image contains four one-dimensional codes, and the four one-dimensional codes are used in turn to represent the steel box girder The block number (5), face number (6), sequence number (7), and other part information (8), so that it can quickly classify all images, find a certain image of a certain face that is needed, and extract The image is shown, among which, other part information (8): When two steel box girders that cooperate with each other are matc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com