Miniature low-frequency omnibearing planar antenna

A plate antenna, low-frequency technology, applied in the direction of antenna grounding switch structure connection, radiation element structure, etc., can solve the problems of vertical polarization and omnidirectionality, vertical installation, high antenna height, etc., to meet special installation requirements Requirements, increasing antenna capacitance, and extending the effect of antenna bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The structural principle and working principle of the present invention are further described below.

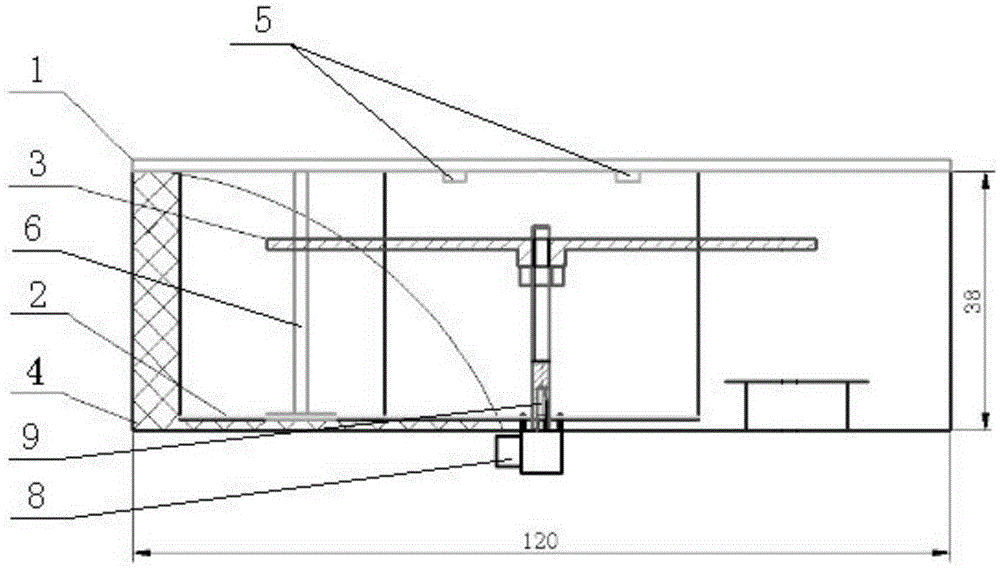

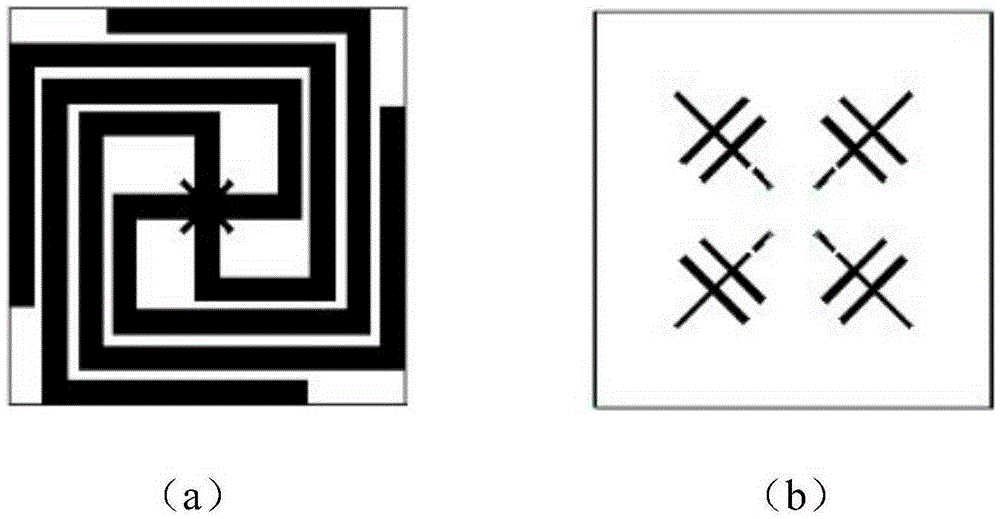

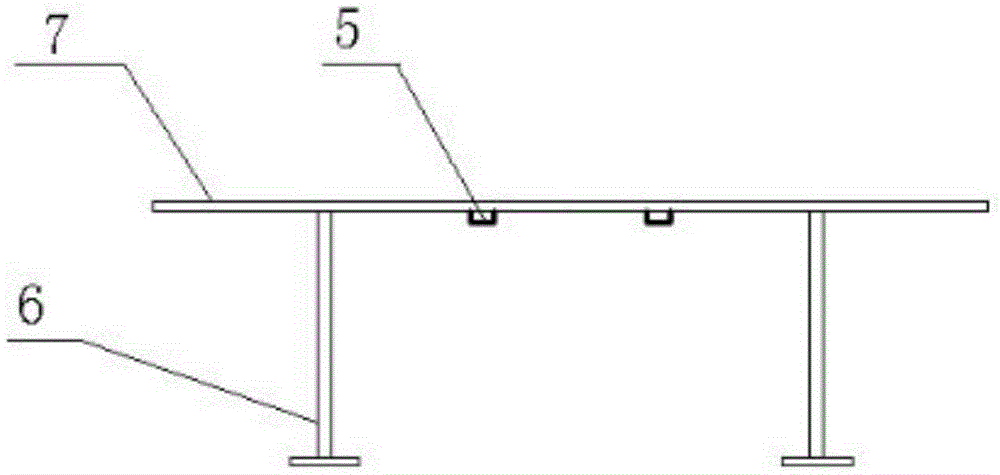

[0022] see figure 1 , figure 2 , image 3 , the present invention is a miniaturized low-frequency omnidirectional plate antenna, including a horizontally placed radiator 1, the four corners of the radiator 1 are fixed above the casing 4 by non-metallic screws, and the radiator 1 is printed by a microstrip. The board 7 is made of four-arm spiral grooves to ensure the electrical performance index of the antenna. The length, width and height of the microstrip printed board 7 are 120mm×120mm×2mm, and the metal coating of the microstrip printed board 7 is " The plane distribution of the swastika character can ensure that the antenna can work within the frequency range. Four fine-tuning resistors 5 are welded in the space reserved on the lower surface of the microstrip printed board 7. The end of the metallized part on the lower surface of the microstrip printed board 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com