Small-sized waste heat and solar energy multifunctional hybrid power generation device

A technology of hybrid power generation and solar energy, which is applied in photovoltaic power generation, generators/motors, electrical components, etc., can solve the problems of discontinuity and intermittency of power generation, industrial waste heat not being efficiently utilized, and single solar energy collection technology and other issues, to achieve the effect of increasing the maximum temperature and light energy utilization rate, low power generation cost, and strong light concentrating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

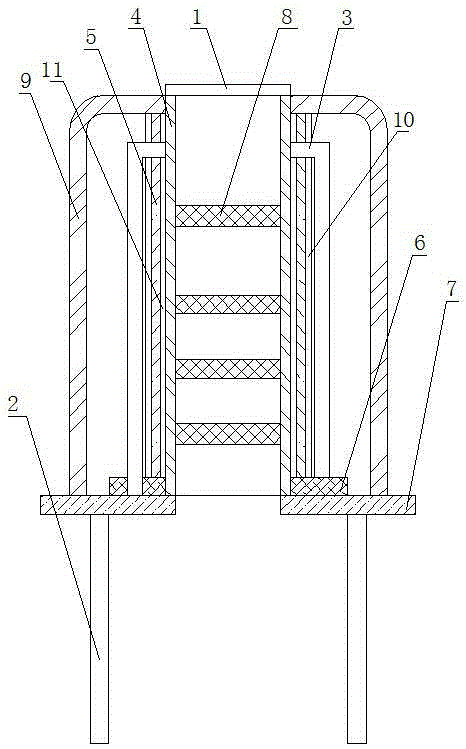

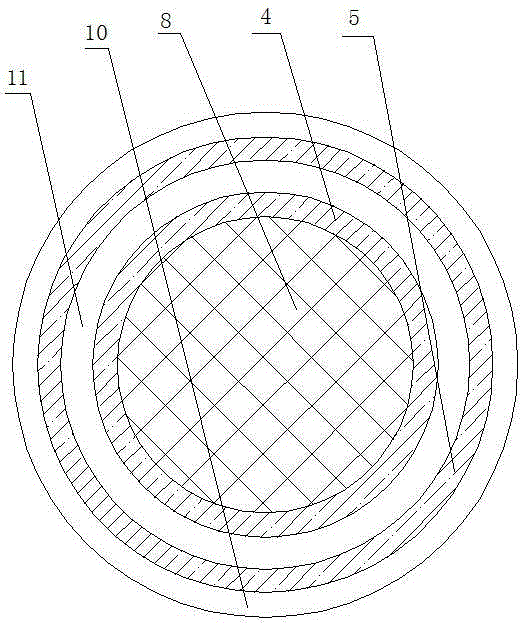

[0022] A small waste heat and solar energy multifunctional hybrid power generation device described in Example 1, the pipeline 4, the fixed column 3 and the annular insulation partition 6 are all put into the insulation box 9, and the The inner diameter of the heat preservation box 9 matches the outer diameter of the annular heat preservation partition 6 .

Embodiment 2

[0024] A small waste heat and solar energy multifunctional hybrid power generation device described in Embodiment 1, the bottom end of the annular support disc 7 is fastened to the pillar 2 .

Embodiment 3

[0026] In the small waste heat and solar energy multifunctional hybrid power generation device described in Example 1, the diameter of the annular support disc 7 is larger than the diameter of the annular heat preservation partition 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com