Composite connecting rod, method for producing same and aircraft ceiling or floor structure including same

A composite structure and connecting rod technology, which is applied in connecting rods, aircraft floors, transportation and packaging, etc., can solve the problems of weak elongation at break and fragility of thermosetting resins, and achieve the effect of improving mechanical properties and avoiding oversize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

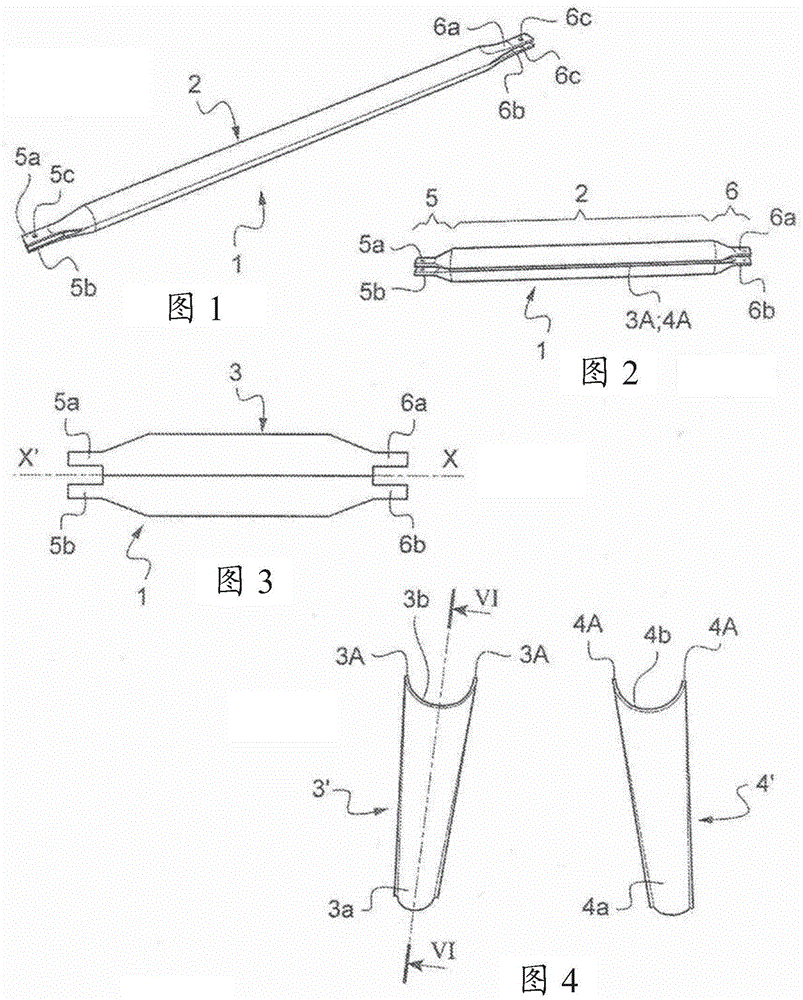

[0059] as in Figure 1 to Figure 3 Specifically shown in , the connecting rod 1 according to the invention comprises a male body 2 with two shells 3 and 4 and two connecting ends 5 and 6, said two shells resting against each other Assembled, said two connecting ends are designed to connect the connecting rod 1 to the adjoining structure by means of two connecting pins (not shown) to be mounted respectively on said ends 5 and 6 . Each connecting end 5, 6 constitutes a yoke having two parallel flat walls 5a and 5b, 6a and 6b spaced on either side of the axis of symmetry X'X of the connecting rod 1 and punched with Two opposing holes 5c, 6c designed to receive one of the connecting shafts.

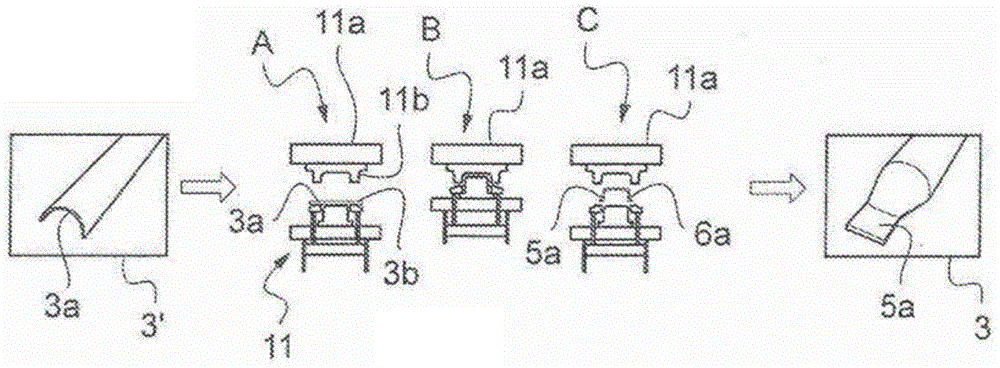

[0060] Figure 4 Shown are two profiled blanks (profiled blanks) 3' and 4' used to manufacture the housings 3 and 4 of the connecting rod 1 of the present invention, shown in two pairs of each housing 3, 4 The ends 3a and 3b, 4a and 4b are shaped to obtain Figure 1 to Figure 3 In front o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com