Processing method for improving content of anthocyanins in purple bud tea

A technology of anthocyanin content and processing method, which is applied in the processing field of increasing the anthocyanin content in purple bud tea, and achieves the effect of low cost and simple and easy processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

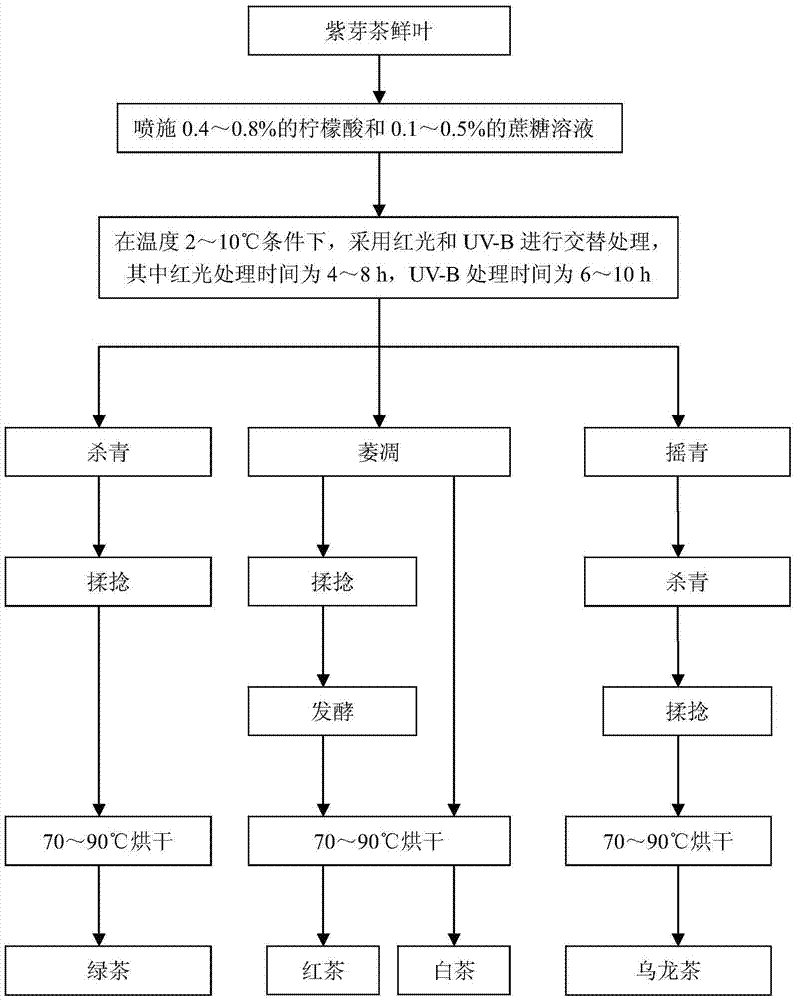

Method used

Image

Examples

Embodiment 1

[0023] 1) 20 kg of fresh leaves of Zijuan spring tea, the picking standard is one bud and one or two leaves;

[0024] 2) Spray the fresh leaves of purple bud tea with 0.5% citric acid and 0.3% sucrose solution;

[0025] 3) At a temperature of 6°C, red light and UV-B were used to alternately treat the fresh leaves of purple bud tea, in which the red light treatment time was 6 hours, and the UV-B treatment time was 7 hours;

[0026] 4) Process the processed fresh purple bud tea leaves into green tea according to traditional techniques, and the drying temperature is 80°C;

[0027] 4.8 kilograms of high anthocyanin green tea were obtained, and the anthocyanin content was 0.159% as detected by the pH differential method, which was higher than that of the traditional processing (0.114%) without processing the fresh leaves of purple bud tea. 39.47%.

Embodiment 2

[0029] 1) 30 kg of fresh leaves of red bud bergamot summer tea, the picking standard is two or three leaves per bud;

[0030] 2) Spray 0.6% citric acid and 0.3% sucrose solution on the fresh leaves of purple bud tea;

[0031] 3) At a temperature of 8°C, red light and UV-B were used to alternately treat the fresh leaves of purple bud tea, in which the red light treatment time was 7 hours, and the UV-B treatment time was 6 hours;

[0032] 4) Process the processed fresh leaves of purple bud tea into white tea according to the traditional process, and the drying temperature is 70°C;

[0033] 7.2 kg of high anthocyanin white tea was obtained, and its anthocyanin content was 0.088% as detected by the pH difference method. 35.38%.

Embodiment 3

[0035] 1) 25 kg of fresh leaves of Mossy Purple Autumn Tea, the picking standard is one bud and one or two leaves;

[0036] 2) Spray 0.7% citric acid and 0.4% sucrose solution on fresh purple bud tea leaves;

[0037] 3) At a temperature of 5°C, red light and UV-B were used to alternately treat the fresh leaves of purple bud tea, in which the red light treatment time was 8 hours, and the UV-B treatment time was 10 hours;

[0038] 4) Process the processed fresh purple bud tea leaves into oolong tea according to traditional techniques, and the drying temperature is 70°C;

[0039] 5.6 kg of high anthocyanin oolong tea was obtained, and its anthocyanin content was 0.082% as detected by the pH difference method, compared with the traditional processing (0.058%) without processing the fresh leaves of purple bud tea, its anthocyanin content increased 41.38%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com