Micro-vibration massage bra and making method thereof

A production method and micro-vibration technology, which can be used in vibration massage, massage accessories, bras, etc., can solve the problems of the vibrator being unable to work, easy to shift, and inconvenient to use, and achieve rapid curing and accelerated crystallization. Speed, avoid discoloration and yellowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

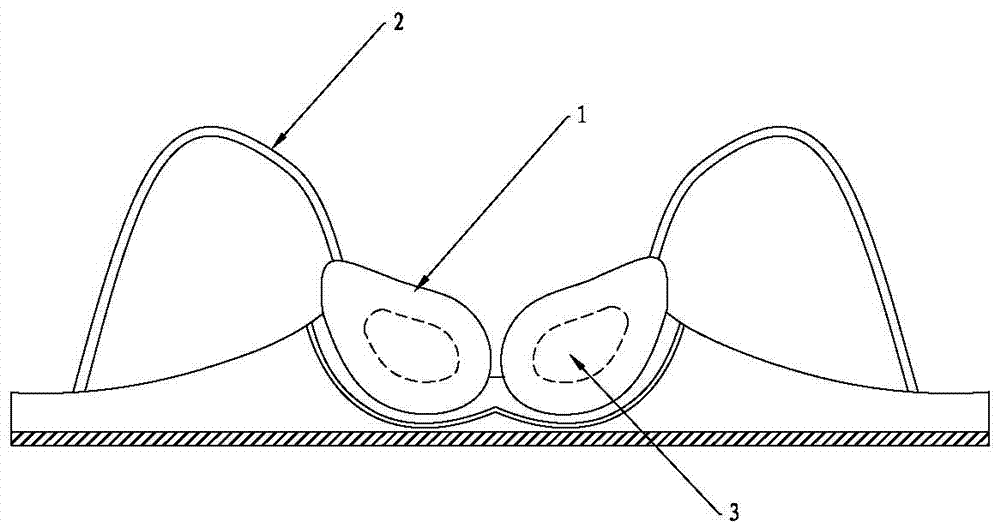

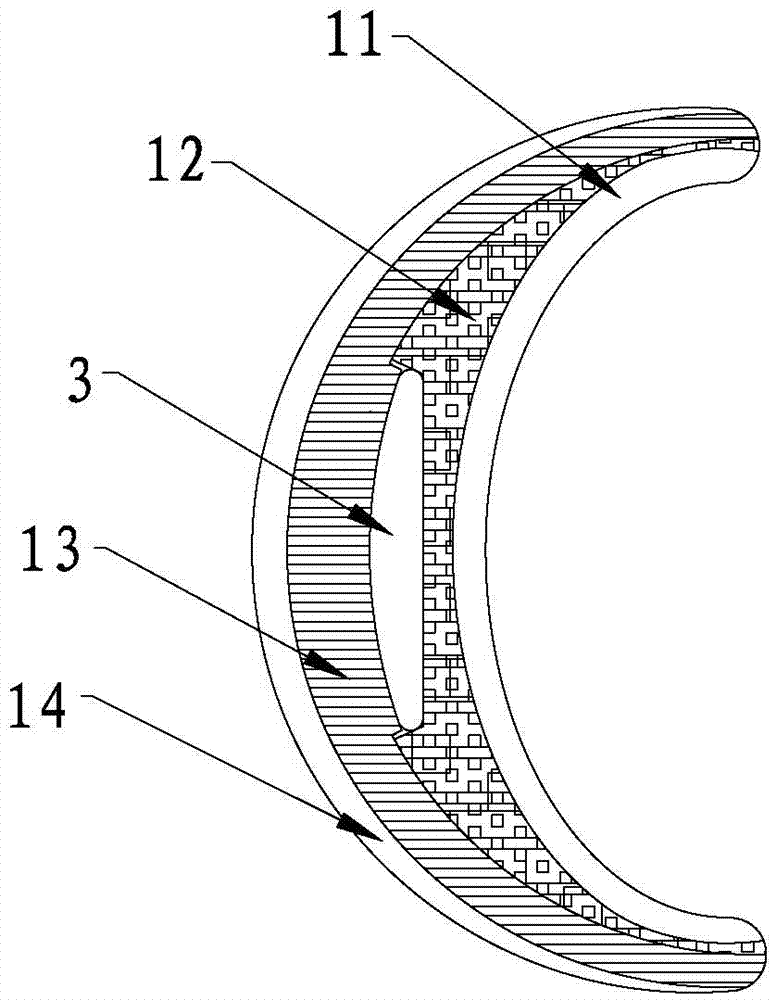

[0054] like Figure 1-2 As shown, a micro-vibration massage bra includes a bra body, and the bra body includes two cups 1, and the two cups 1 all include an inner cotton layer 11, a first vertical cotton layer 12, a second cotton layer, and Two upright cotton layers 13 and an outer cotton layer 14, the first upright cotton layer 12 is provided with a storage cavity, and a micro-vibration massager 3 is fixedly arranged in the storage cavity, and the surface of the micro-vibration massager 3 is coated with a waterproof membrane, and the waterproof membrane A suede layer is provided on the surface, and the second upright cotton layer 13 cooperates with the first upright cotton layer 11 to seal the storage cavity.

[0055] Further, the micro-vibration massage bra also includes an underbar located below the two cups 1, and two shoulder straps 2, and each shoulder strap 2 connects the underbar and one cup 1.

[0056] Further, the micro-vibration massager 3 is provided with a wirele...

Embodiment 2

[0090] In this embodiment, the inner surface of the inner cotton layer 11 includes a sponge layer and a fiber cloth layer arranged on the inner side of the sponge layer, the fiber cloth layer is an inelastic fiber cloth, and the outer cotton layer 14 is provided with a sponge layer.

[0091] Further, the thickness of the middle part of the first vertical cotton layer 12 and the middle part of the second vertical cotton layer 13 is 12 mm, and the thickness of the middle part of the inner cotton layer 11 and the middle part of the outer cotton layer 14 is 2 mm.

[0092] The present invention also provides a method for manufacturing a micro-vibration massage bra, comprising the following steps:

[0093] A. The first vertical cotton layer 12 and the inner cotton layer 11 are heat-pressed to form the first composite layer, and the first vertical cotton layer 12 is heat-pressed to form a storage chamber; the heat-pressing temperature is 180°C, and the pressing time is 65s. The pres...

Embodiment 3

[0117] In this embodiment, the thickness of the middle part of the first upright cotton layer 12 and the middle part of the second upright cotton layer 13 is 8mm, and the thickness of the middle part of the inner cotton layer 11 and the middle part of the outer cotton layer 14 is 4mm.

[0118] The present invention also provides a method for manufacturing a micro-vibration massage bra, comprising the following steps:

[0119] A. The first vertical cotton layer 12 and the inner cotton layer 11 are heat-pressed to form the first composite layer, and the first vertical cotton layer 12 is heat-pressed to form a storage chamber; the heat-pressing temperature is 220°C, and the pressing time is 55s. The pressure is 0.45MPa;

[0120] B. The second upright cotton layer 13 is thermally bonded to the outer cotton layer to form a second composite layer; the thermal bonding temperature is 220° C., the bonding time is 55 s, and the pressure is 0.45 MPa;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com