D-glucosamine preparation method

A technology of glucosamine and glucosamine hydrochloride, applied in the chemical field, can solve the problems of cumbersome operation, high cost, and methanol toxicity, and achieve the effects of reducing sewage generation, preventing yellowing and discoloration, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

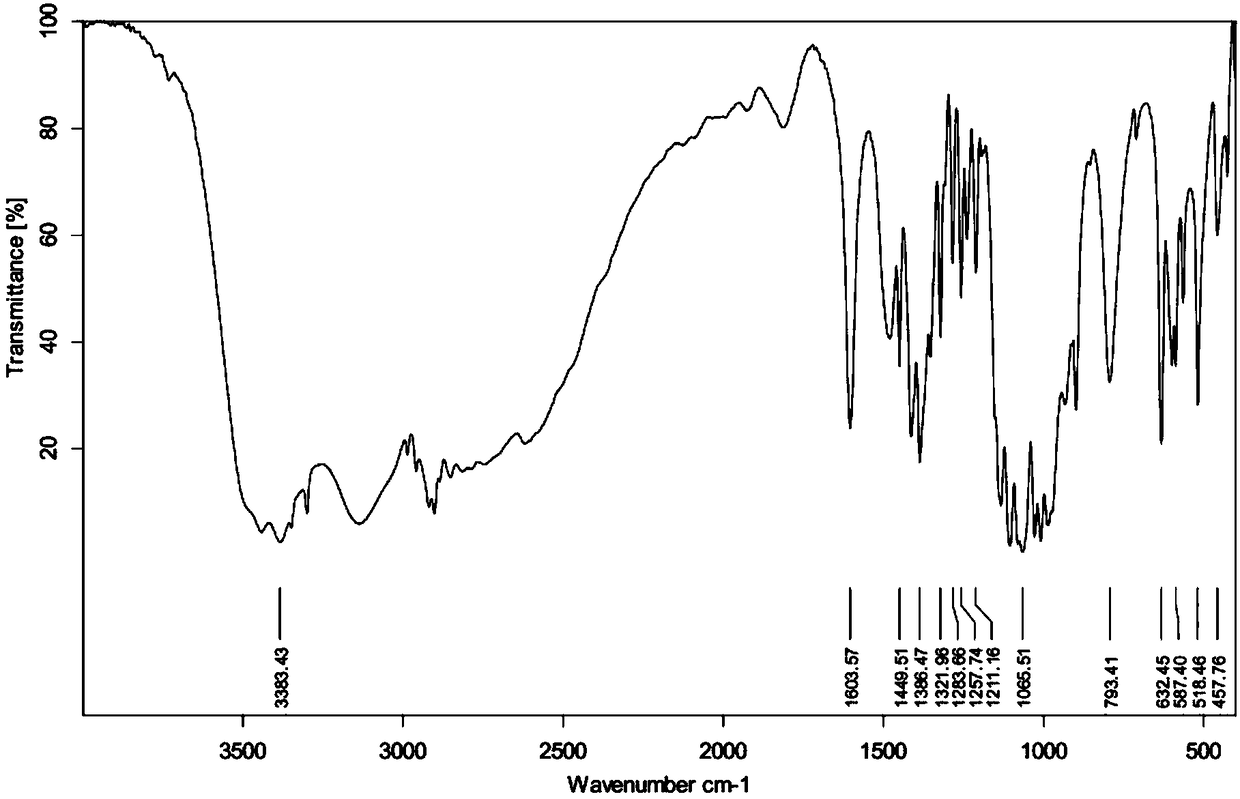

Embodiment 1

[0034] Start stirring, extract 750L of ethanol with a concentration of 93% and pump it into a 1500L reactor, then pulverize 220kg to 100 purpose D-glucosamine hydrochloride and put it into the reactor, open the steam valve, and control the temperature of the reactor at 27°C , after the temperature is reached, start stirring, then slowly add 100kg of diethylamine to the reaction kettle, keep the temperature at 27°C and react for 4 hours. The dried material was put into the reactor, and 800L of ethanol solvent (concentration of 97%) was pumped for soaking and cleaning. At the same time, the stirring was started, and the soaking and cleaning were carried out for 3 hours. Move the dried material to a vacuum drying box for drying until it is dry. The water bath temperature of the drying box is controlled at 50℃±5℃, the vacuum degree is controlled above -0.09MPa, and the drying time is 5 hours to obtain 166kg of finished product. 90.8%, the chloride ion content is 0.068%, and the sp...

Embodiment 2

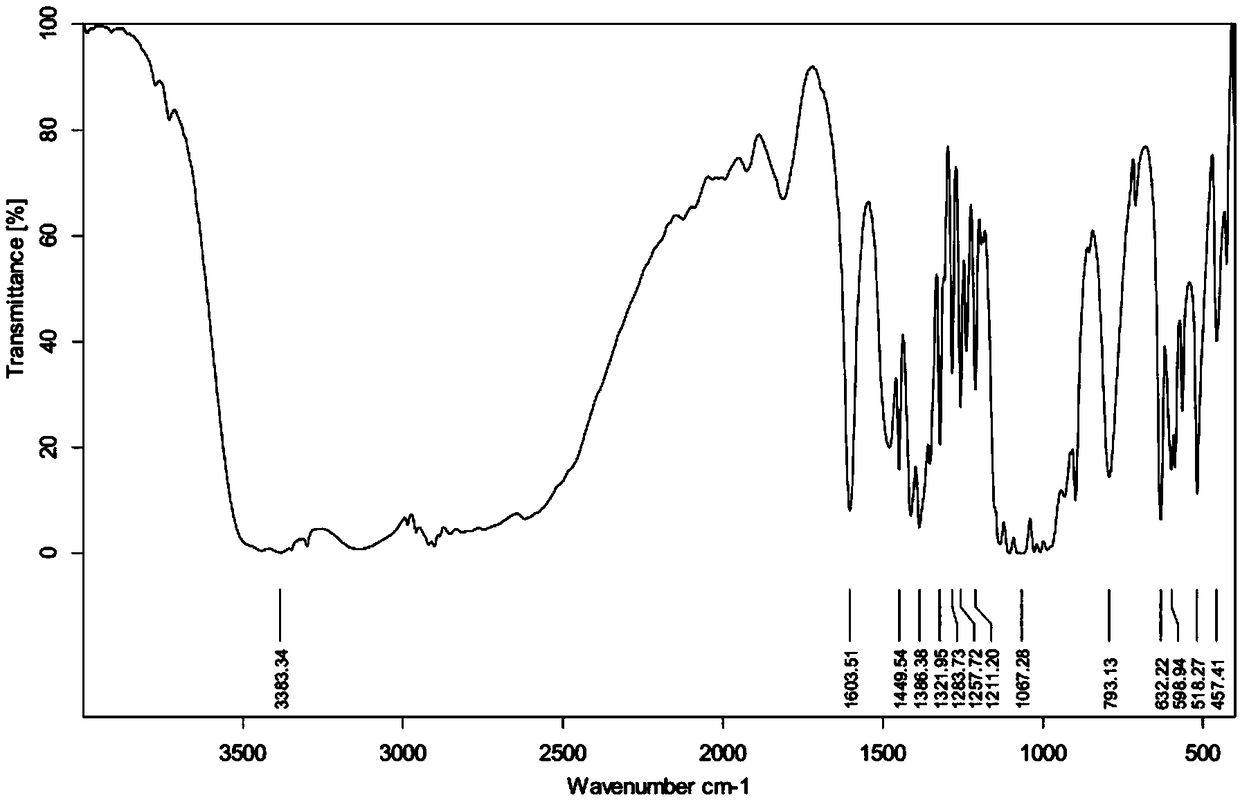

[0036]Start stirring, extract 620L of ethanol with a concentration of 88% and pump it into a 1500L reactor, then pulverize 220kg to 100 purpose D-glucosamine hydrochloride and put it into the reactor, open the steam valve, and control the temperature of the reactor at 32°C , after the temperature is reached, start stirring, then slowly add 90kg of diethylamine and 40kg of triethylamine to the reaction kettle, keep the temperature (32°C) and react for 8 hours. After the reaction time is reached, put the feed liquid into the centrifuge for centrifugation. Until it is dried, put the dried material into the reactor, pump 600L of ethanol solvent (93% concentration) for soaking and cleaning, at the same time start stirring, soak and clean for 2 hours, after the soaking and cleaning time is reached, put the material liquid again Put into a centrifuge for centrifugation until it becomes dry, and move the dried material to a vacuum drying box for drying. The water bath temperature of th...

Embodiment 3

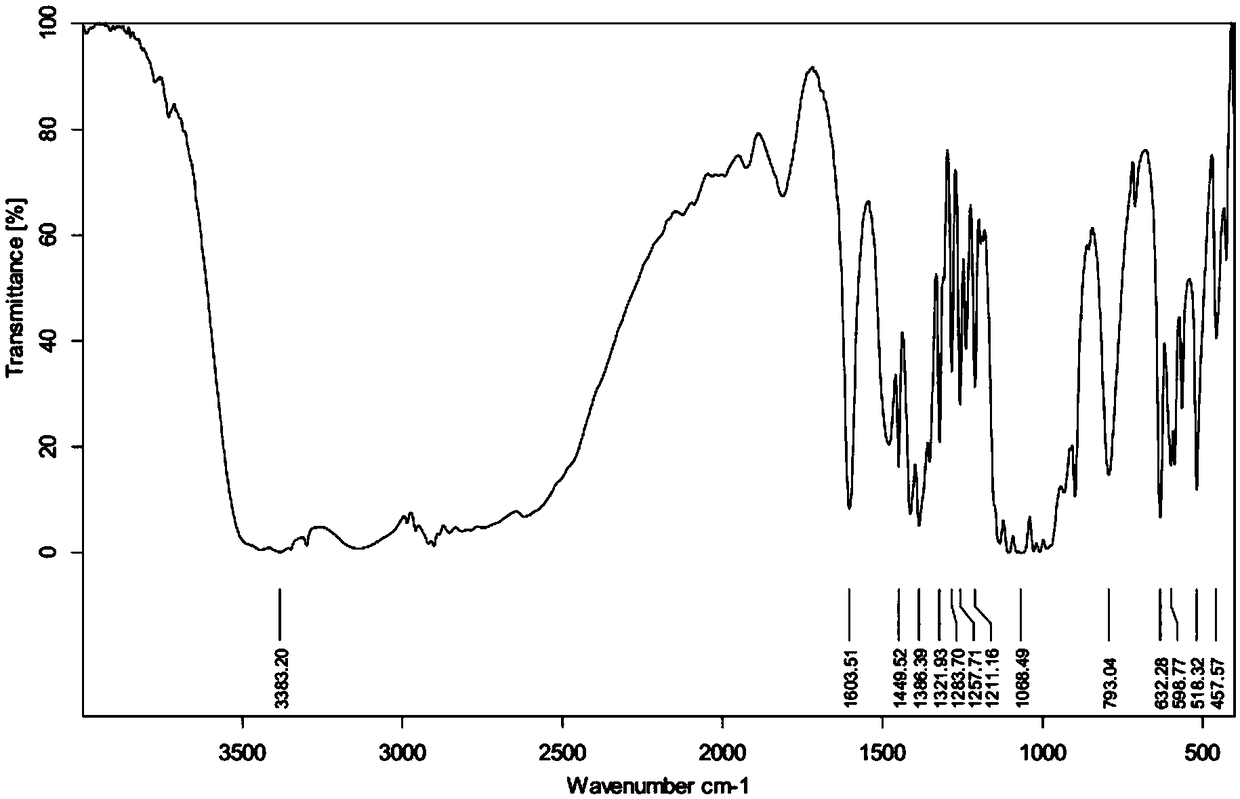

[0038] Start stirring, extract 700L of ethanol with a concentration of 90% and pump it into a 1500L reactor, then pulverize 220kg to 100 purpose D-glucosamine hydrochloride and put it into the reactor, open the steam valve, and control the temperature of the reactor at 37°C , after the temperature is reached, start stirring, then slowly add 30kg dimethylamine and 80kg diethylamine to the reactor, keep the temperature (37°C) and react for 6 hours. After the reaction time is reached, put the feed liquid into the centrifuge for centrifugation. Until it is dried, put the dried material into the reactor, pump 700L of ethanol solvent (95% concentration) for soaking and cleaning, at the same time start stirring, soak and clean for 2 hours, after the soaking and cleaning time is reached, put the material liquid again Put into a centrifuge for centrifugation until it becomes dry, and move the dried material to a vacuum drying box for drying. The water bath temperature of the drying box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com