Perforating machine for aluminum profiles

A technology for punching machines and aluminum profiles, which is applied in the field of punching machines, can solve the problems of reduced production efficiency, increased production costs, and scrapped aluminum profiles, and achieves the effects of safe processing, improved work efficiency, and comprehensive drilling work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

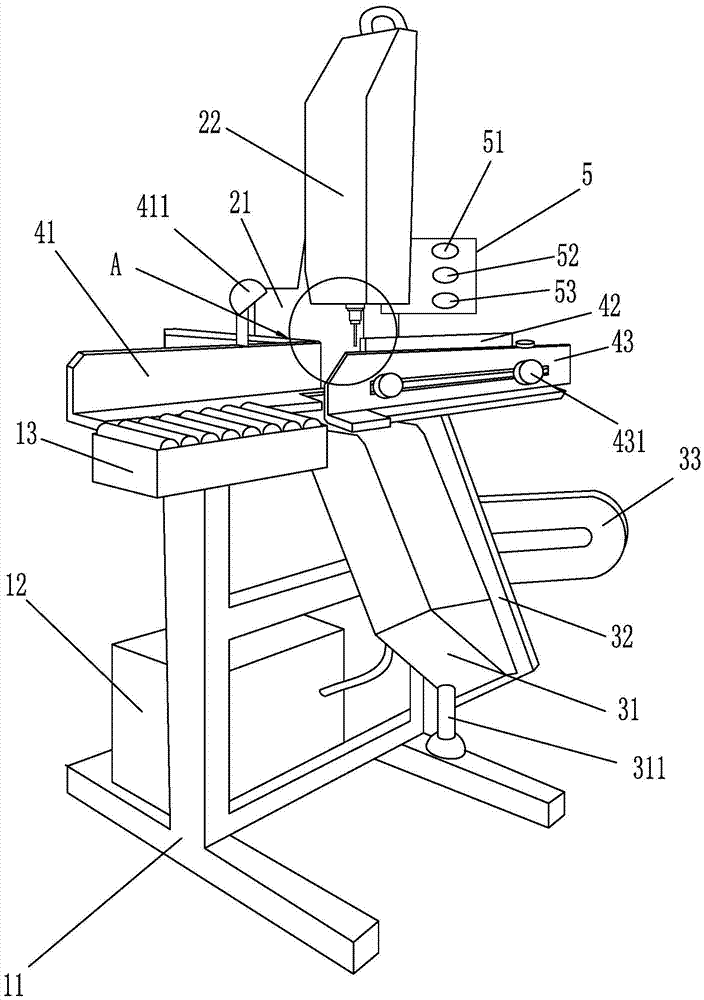

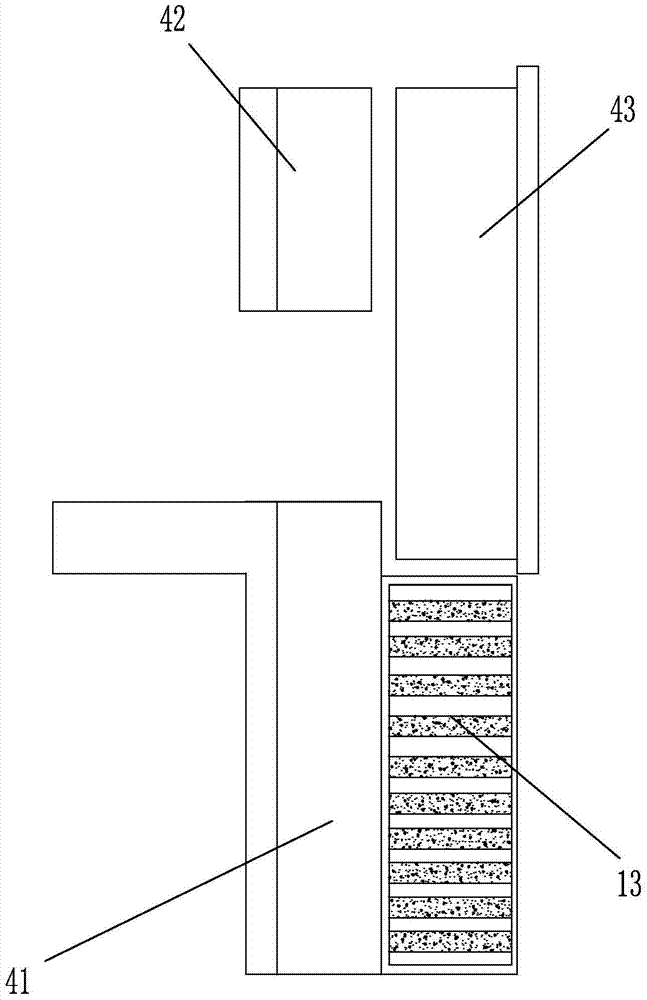

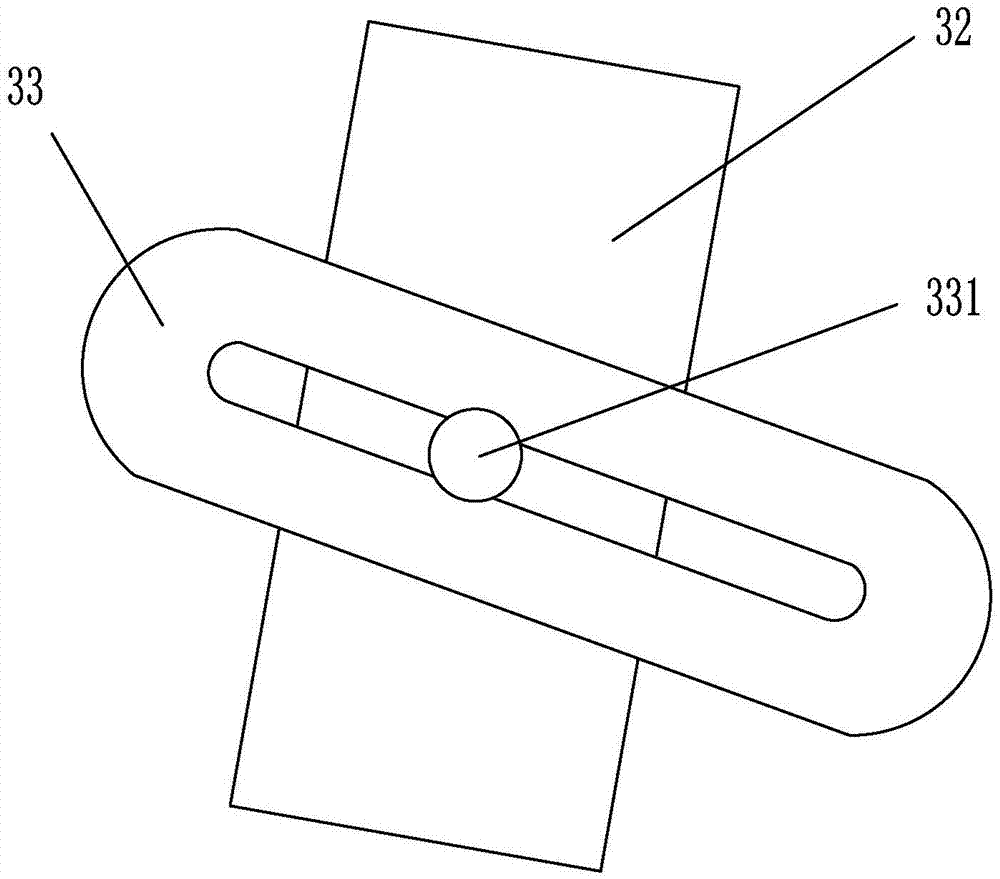

[0027] like Figure 1 to Figure 5As shown, a punching machine for aluminum profiles includes a working platform, a drilling mechanism and an auxiliary fixture mechanism. The working platform is provided with a drilling mechanism and an auxiliary fixture mechanism. The working platform includes a fixed support frame 11, a control motor and Send out roller group 13, control motor is fixed on the fixed support frame 11, send out roller group 13 is fixed on the upper end of fixed support frame 11, drilling mechanism includes upper punching device and lower punching device, and lower punching device is positioned at the upper punching hole. The lower end of the device, the upper punching device includes a mobile support column 21, a first punching tool 23 and a first moving arm 22, the first punching tool 23 is located in the first moving arm 22, and the first moving arm 22 is fixedly connected to the In the mobile support column 21, the mobile support column 21 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com