Water wall climbing robot with magnet brackets connected through singular springs

A wall-climbing robot and water-cooled wall technology, applied to instruments, motor vehicles, and the use of ultrasonic/sonic/infrasonic waves, etc., can solve the problems of large area, inconvenient measurement, and scattered locations for water-cooled wall tube thickness detection, and achieve automation Tall, compact and lightweight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

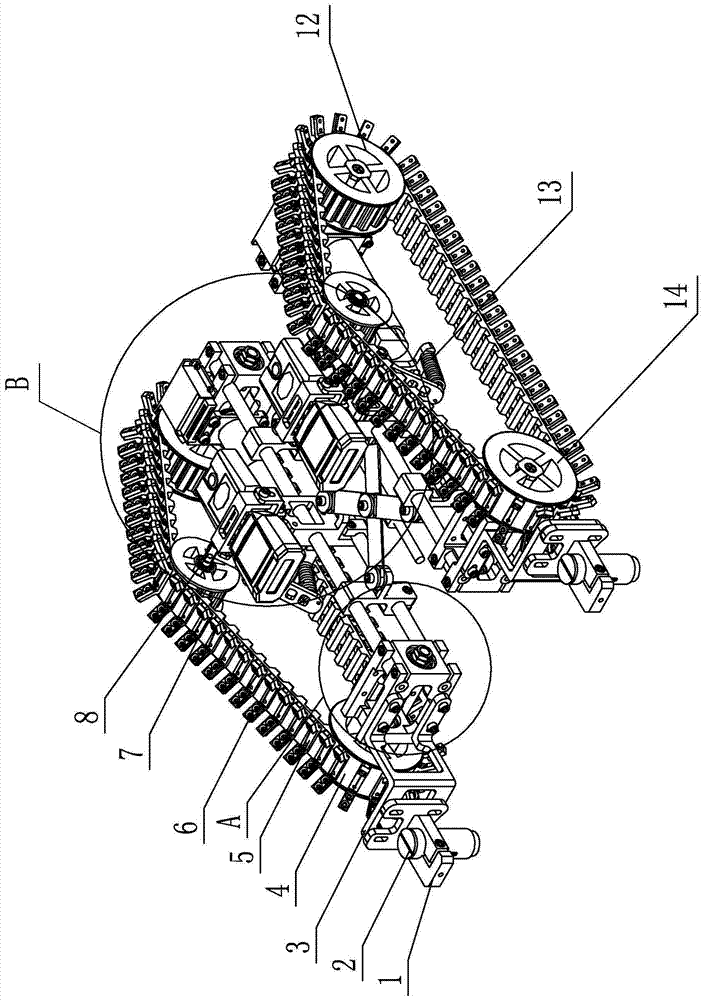

[0018] Specific implementation mode one: refer to Figure 1 to Figure 5 Describe this embodiment in detail. A water-cooled wall-climbing robot using a single spring connected to a magnet bracket described in this embodiment includes: a connecting part and two wheel sets with left-right symmetrical structures;

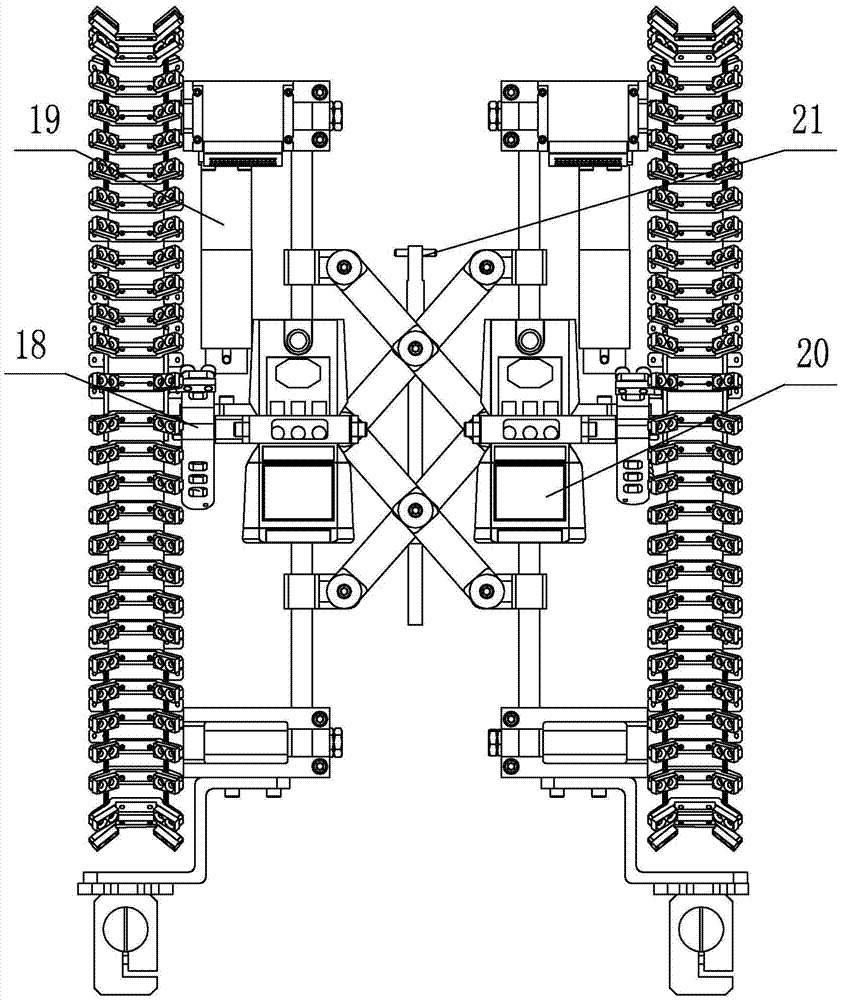

[0019] The connection part includes: a shock absorber group, a shock absorber support frame 16 and a lead screw 21;

[0020] The shock-absorbing sheet group is in the shape of a grid, and the shock-absorbing sheet group can be stretched horizontally and vertically. The shock-absorbing sheet support frame 16 includes two parts separated from each other. The two parts of 16 are hinged, and the lead screw 21 is used to drive the shock absorber group to perform telescopic movement, and the two wheel groups are respectively fixed on the two parts of the shock absorber support frame 16;

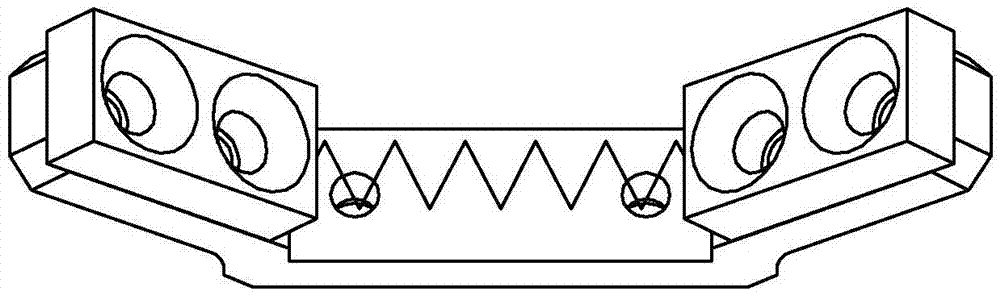

[0021] Each wheel set includes: synchronous belt 4, a plurality of magnet brackets 5, p...

specific Embodiment approach 2

[0031] Specific embodiment two: This embodiment is a further description of a water-cooled wall climbing robot using a single spring connected to a magnet bracket as described in specific embodiment one. In this embodiment, it also includes: a front probe bracket 1, a probe Sleeve 2 and rear probe holder 3;

[0032] The rear probe bracket 3 is fixed on the support frame 17 of the timing belt slave wheel, the front probe bracket 1 is fixed on the rear probe bracket 3, the probe sleeve 2 is fixed on the front probe bracket 1, and the probe sleeve 2 is used to support the ultrasonic thickness gauge 20 probes.

specific Embodiment approach 3

[0033] Specific embodiment three: This embodiment is a further description of a water-cooled wall climbing robot that uses a single spring connected to a magnet bracket as described in specific embodiment one. In this embodiment, the synchronous belt master wheel 12 and the synchronous belt slave wheel The cross sections of 14 are all trapezoidal.

[0034] The synchronous belt master wheel 12 and the synchronous belt slave wheel 14 are the main components that drive the synchronous belt 4 to move. The sections of the synchronous belt master wheel 12 and the synchronous belt slave wheel 14 are trapezoidal; function, and can make the wall-climbing robot play the role of shock absorption when encountering obstacles in the process of crawling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com