Continuous sealing structure of water-soluble film packaging machine

A water-soluble film, packaging machine technology, applied in packaging sealing/fastening, packaging, transportation packaging, etc., can solve problems such as low sealing efficiency and unstable sealing strength, and achieve stable sealing strength and sealing effect. Excellent, improve the effect of packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

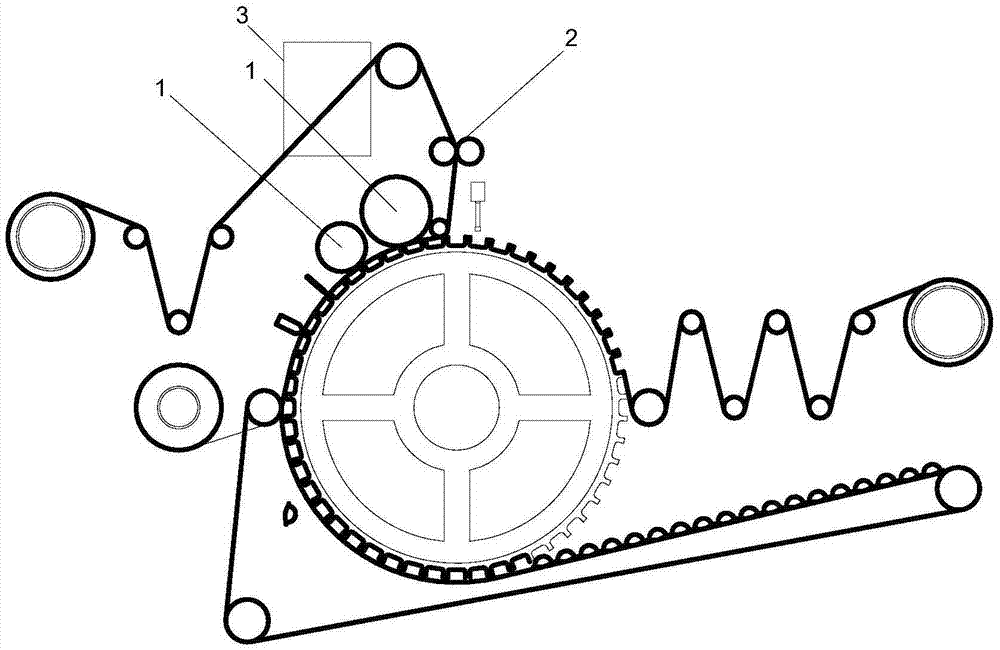

[0021] refer to figure 1 , the present invention provides a continuous sealing structure for a water-soluble film packaging machine, which includes a frame, and a sealing roller is arranged on the sealing station of the water-soluble film packaging machine of the frame, and also includes a The sealing roller is used together with a humidity control mechanism for pretreatment of the water-soluble film before sealing.

[0022] Further, there are two sealing rollers 1, which are sequentially arranged on the sealing station of the water-soluble film packaging machine. In the case where two sealing rollers 1 are provided compared to one, the pressing area per unit time is larger, which can improve the sealing efficiency to a certain extent.

[0023] Further, the sealing roller 1 is a heated rubber roller, and the heat sealing temperature is controlled at 70°C-85°C. If the upper film and the bottom film of the film are directly pressed together at room temperature, the sealing effe...

Embodiment 2

[0026] refer to figure 1 , the present invention provides a continuous sealing structure of a water-soluble film packaging machine, which includes a frame, and a sealing roller 1 is arranged on the sealing station of the water-soluble film packaging machine of the frame, and also includes a Cooperating with the sealing roller 1, a humidity control mechanism is used to pretreat the upper film of the water-soluble film before sealing.

[0027] Further, there are two sealing rollers 1, which are sequentially arranged on the sealing station of the water-soluble film packaging machine. There are two sealing rollers 1, and the pressing area per unit time is larger, which can improve the sealing efficiency to a certain extent.

[0028] Further, the sealing roller 1 is a heated rubber roller, and the heat sealing temperature is controlled at 70°C-85°C.

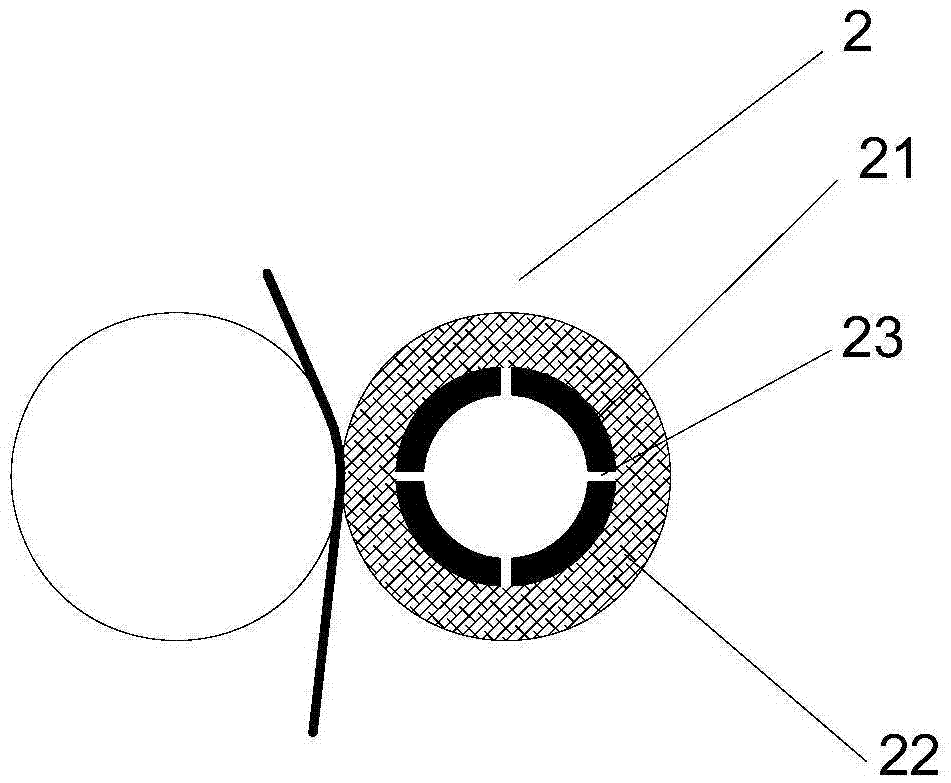

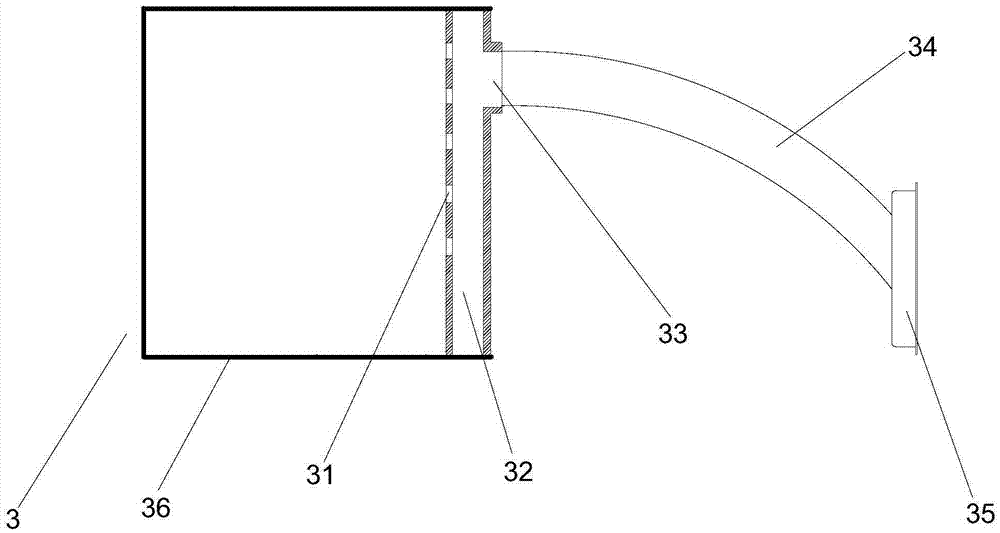

[0029] In this embodiment, the humidity control mechanism is set as an indirect water seal mechanism 3 that indirectly covers the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com