A method for preparing manganese-based lithium-ion battery cathode materials based on alkali metal-liquid ammonia method

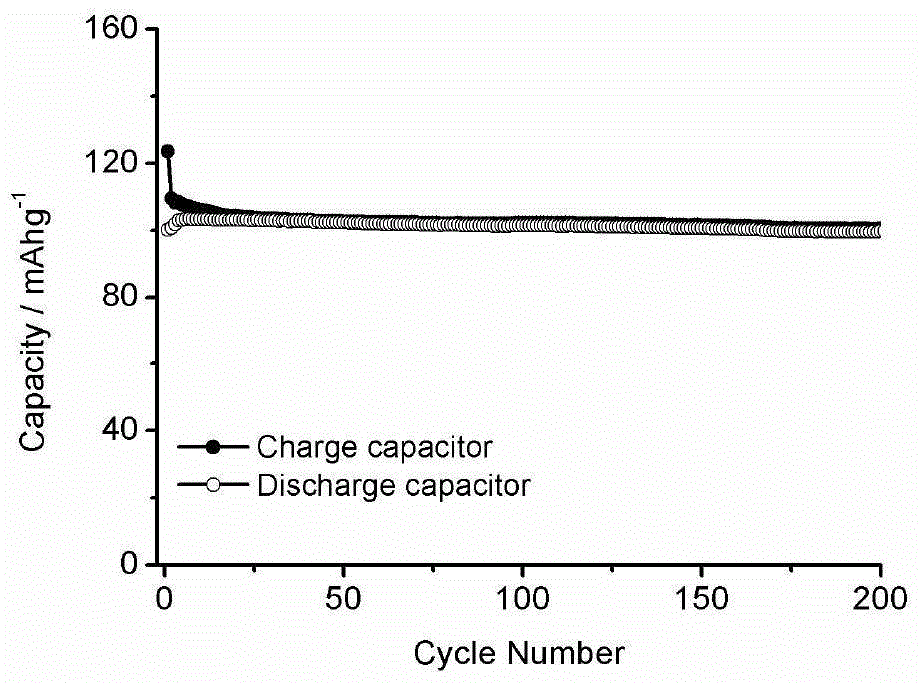

A technology for lithium-ion batteries and cathode materials, applied in the new preparation of manganese-based materials, based on the alkali metal-liquid ammonia method to prepare manganese-based lithium-ion battery cathode materials, the field of cathode materials for lithium-ion batteries, can solve the problem that the cost is difficult to increase Large-scale production, irregular shape of crystal grains, complex precursor control and other issues, to achieve the effect of improving structural stability, low production cost, and capacity retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

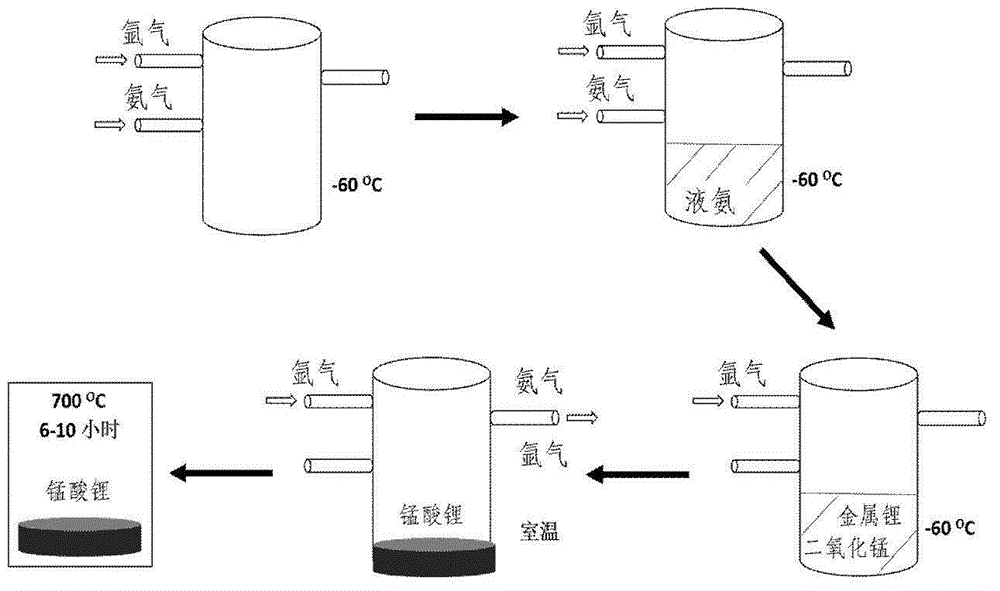

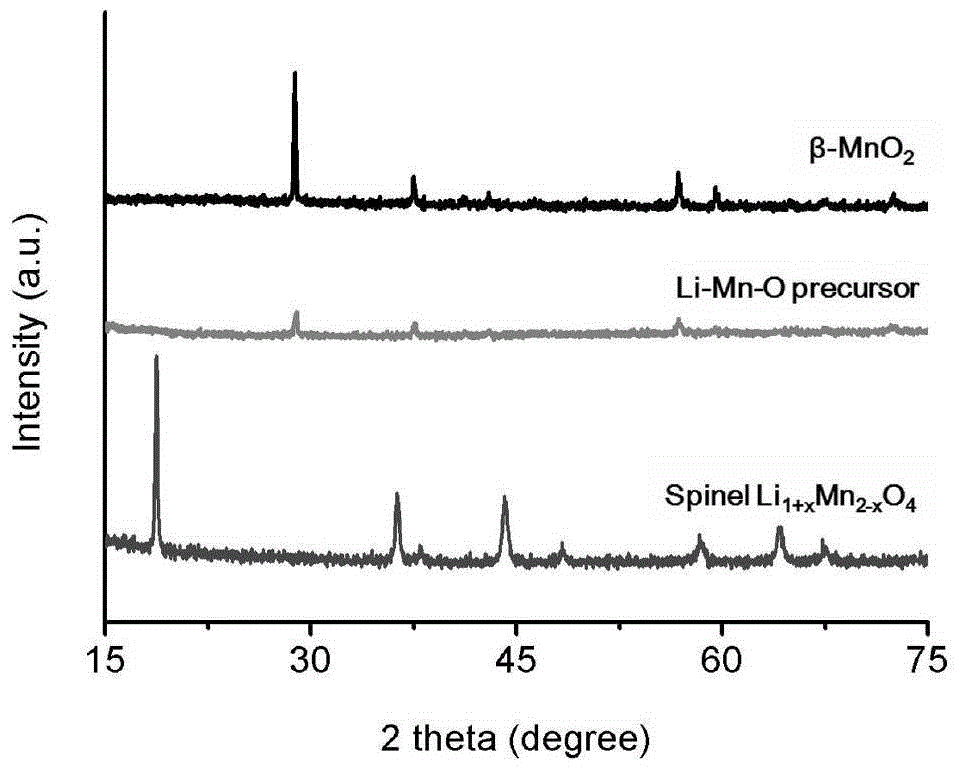

[0020] Embodiment 1: Spinel type lithium manganese oxide material

[0021] A method for preparing manganese-based lithium ion battery cathode materials based on an alkali metal-liquid ammonia method comprises the following steps: obtaining a certain volume of pure liquid ammonia solution by cooling ammonia gas under a protective atmosphere. Manganese dioxide and metal lithium were added to the liquid ammonia solution in sequence, and the stirring speed was kept at 800r / min. The molar ratio of manganese dioxide to metallic lithium is 1:2, which ensures that the obtained lithium manganate has a relatively pure spinel structure, dispersibility and uniformity. Stir evenly at low temperature for 1 hour, and keep the reaction temperature at -60°C. After the reaction is complete, slowly increase the temperature, and wait for the liquid ammonia to evaporate naturally. Collect the residual solids in the container and put them into the reaction furnace, anneal at 800°C for 4 hours, coo...

Embodiment 2

[0022] Embodiment 2: layered lithium manganate material

[0023] Obtain a certain volume of pure liquid ammonia solution by cooling ammonia gas under a protective atmosphere.

[0024] Manganese dioxide and metal lithium were added to the liquid ammonia solution in sequence, and the stirring speed was kept at 800r / min. Wherein the molar ratio of manganese dioxide to metallic lithium is 1:1, changing the ratio can control the crystal structure of lithium manganate, and obtain layered LiMnO 2 Cathode material. Stir evenly at low temperature for 3 hours, keep the reaction temperature at -60°C, raise the temperature slowly after the reaction is complete, and wait for the liquid ammonia to evaporate naturally. Collect the residual solids in the container and put them into the reaction furnace, anneal at 600°C for 8 hours, and cool naturally. After powder treatment, layered LiMnO is finally obtained. 2 Cathode material. The protective gas used in the above steps is argon. The re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com