Cold box low-temperature separation method for PDH project

A separation method and cold box technology, which are used in cold treatment separation, hydrocarbon purification/separation, chemical instruments and methods, etc., can solve the problems of short catalyst life and large investment, and achieve easy control, strong operability and high recovery rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

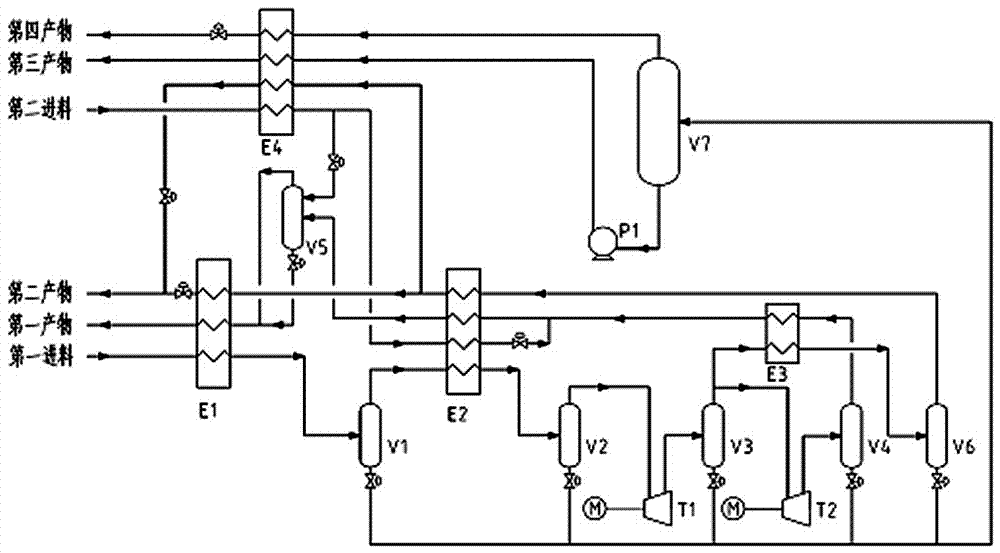

[0013] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, the cold box low-temperature separation method of the PDH project of the present invention includes four plate-fin heat exchangers, seven gas-liquid separators, two expansion units and a cryogenic pump.

[0014] The first plate-fin heat exchanger E1 has a hot flow channel and two cold flow channels, in which the first feed material with a temperature of 35~50°C passes through the hot flow channel of E1 and is cooled to -40~-55°C before entering the first The gas stream separated by the gas-liquid separator V1 and V1 enters the hot flow channel of the second plate-fin heat exchanger E2, wherein the second plate-fin heat exchanger E2 is provided with two hot flow channels and two cold flow channels, the above The gas stream is cooled to -100~-115°C in the first heat flow channel of the second plate-fin heat exchanger E2 and then enters the second gas-liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com