System and method for removing dme from mtp products

A product and removal technology, which is applied in the direction of chemical instruments and methods, hydrocarbons, hydrocarbon purification/separation, etc., can solve the problems of MTP product separation system complexity, reduction of enterprise profit margins, high construction investment, etc., to reduce equipment Investment cost, guaranteed purity, low equipment investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the drawings and embodiments, but the content of the present invention is not limited thereto. In the present invention, C3 refers to the component with 3 carbon atoms in the MTP product; C3 below or C3- refers to the component with less than 3 carbon atoms in the MTP product; C4 refers to the component with 4 carbon atoms in the MTP product Components; C4 or more or C4+ refers to components with more than 4 carbon atoms in the MTP product.

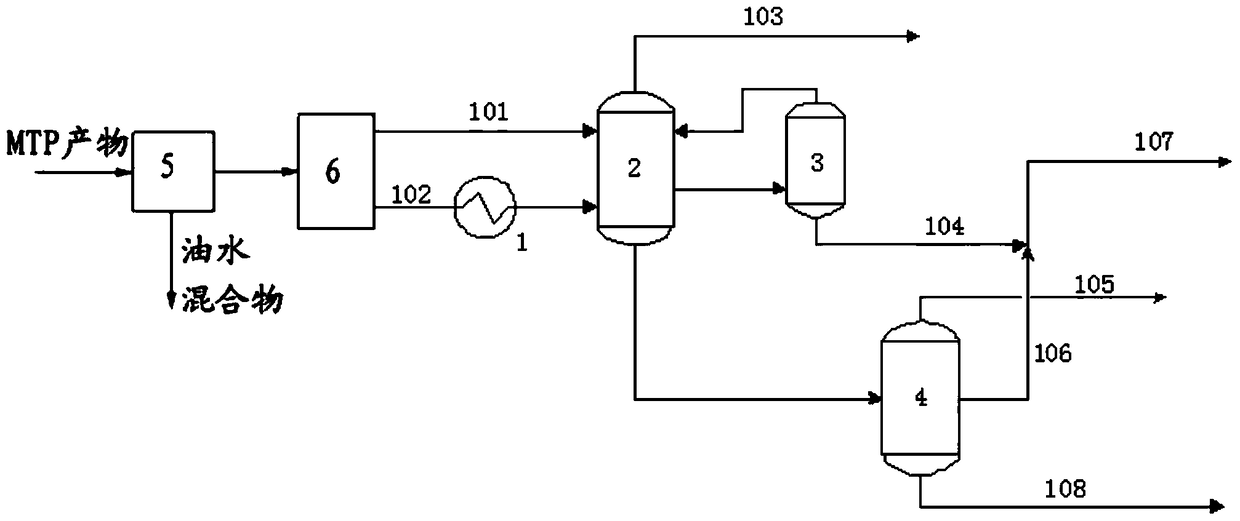

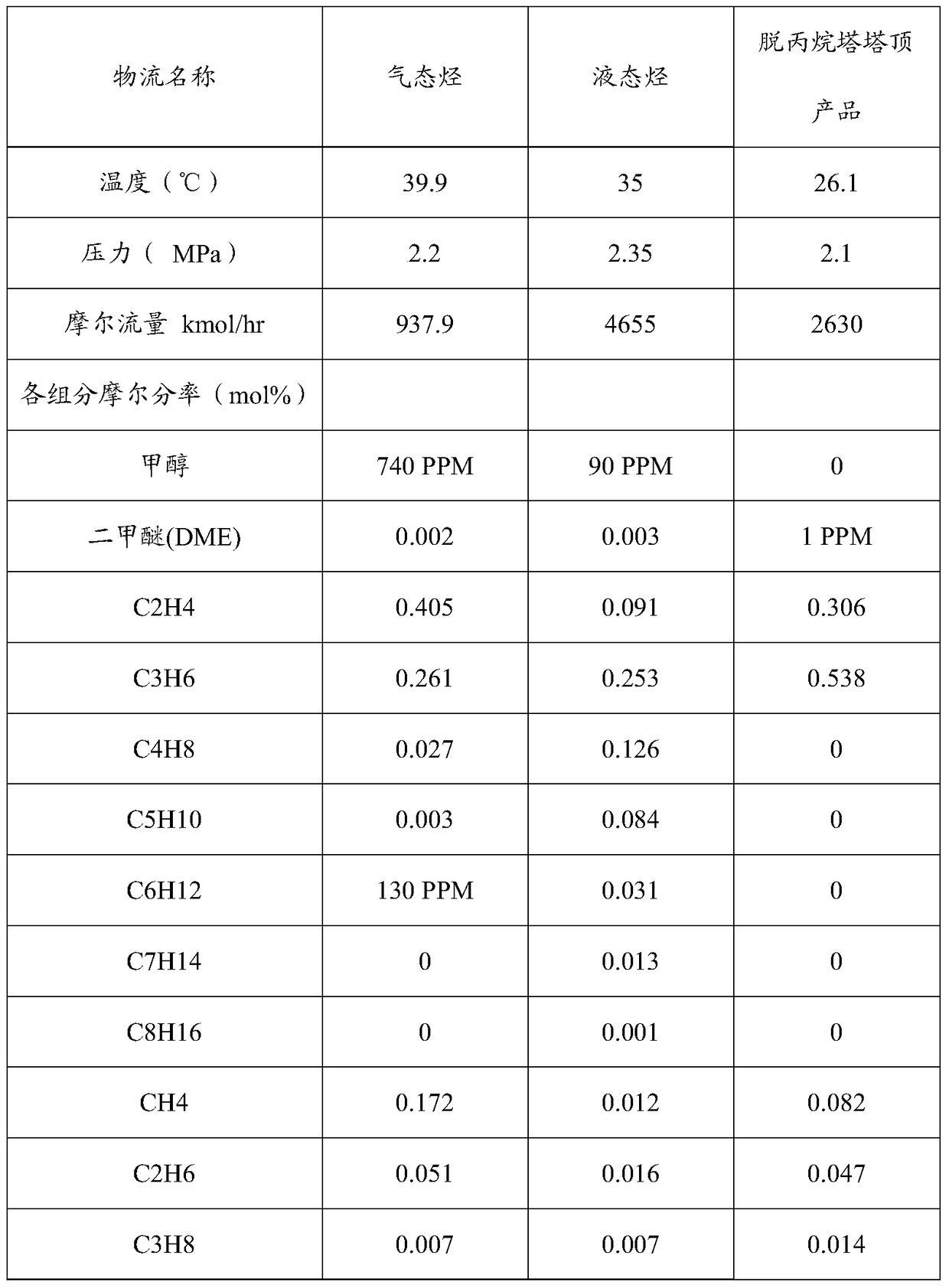

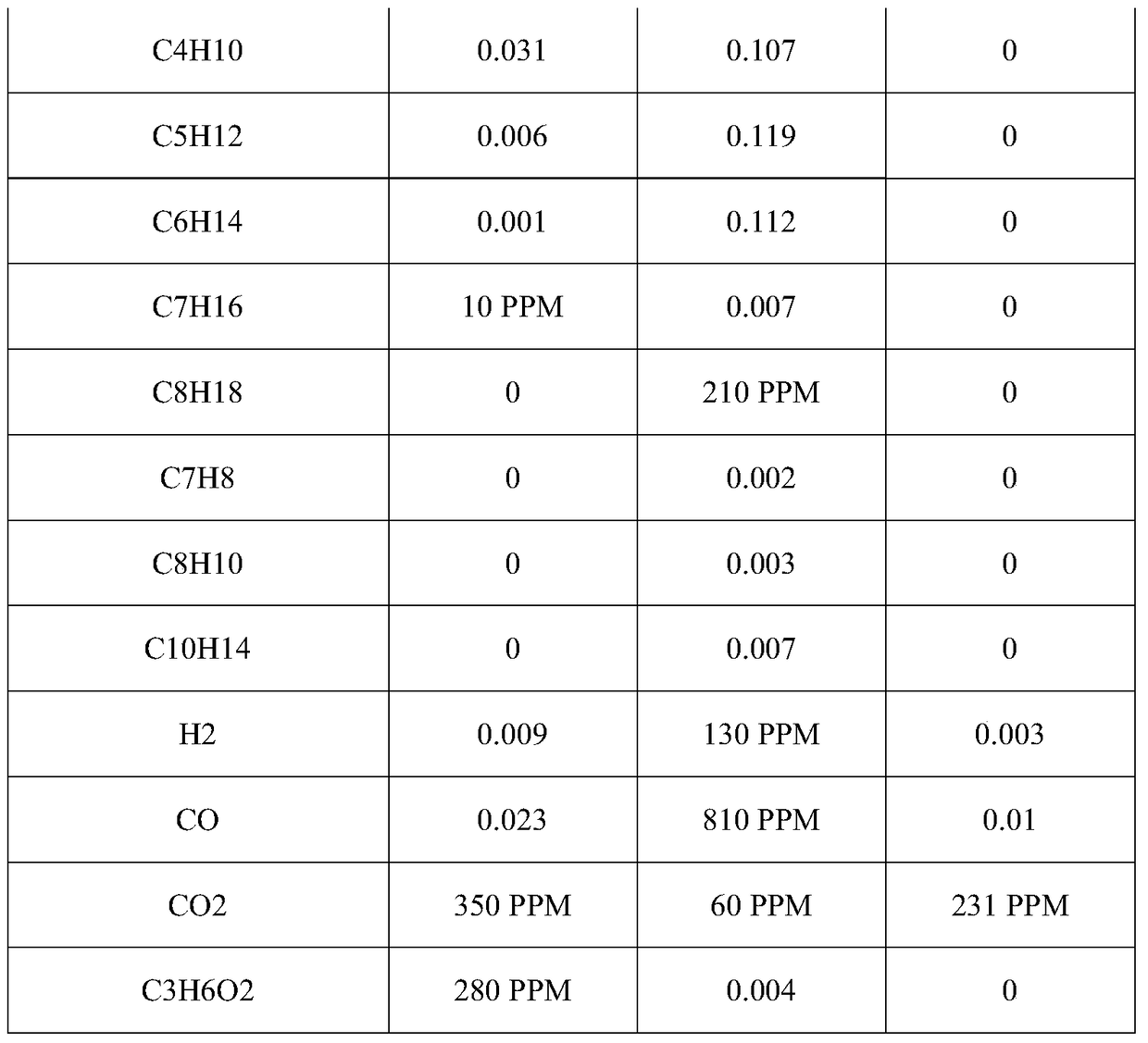

[0027] Such as figure 1 As shown, the DME removal system of the present invention includes a quenching unit 5 (also called a quenching unit), a compression unit 6 , a depropanizer 2 and a de-DME tower 3 . Wherein, the quenching unit 5 is used for quenching the MTP product from the propylene synthesis reactor, so that part of the components in the MTP product are condensed to form an oil-water mixture, thereby separating the MTP product into the first gas pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com