Aqueous diamond grinding fluid with continuously suspending abrasives and preparation method thereof

A diamond and grinding liquid technology, applied in the field of water-based diamond grinding liquid, can solve the problems of time-consuming and labor-intensive use, reduce the convenience of using the grinding liquid, and cumbersome processes, and achieve the effects of simple preparation process, enhanced bonding force, and improved use convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

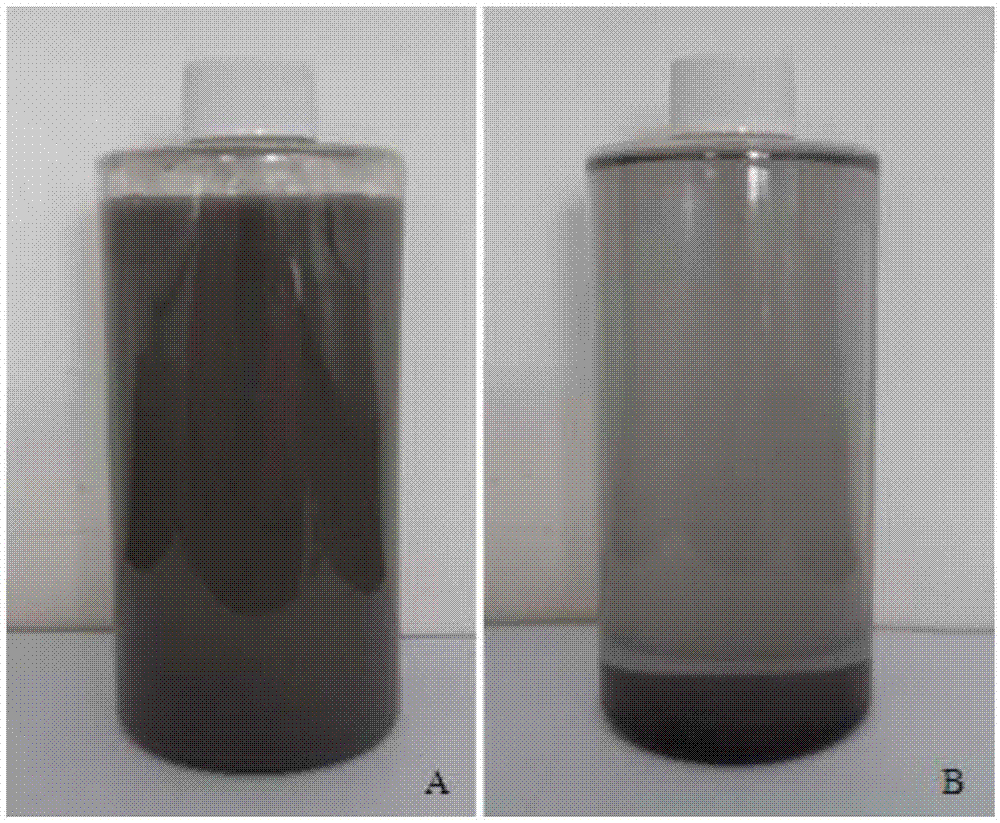

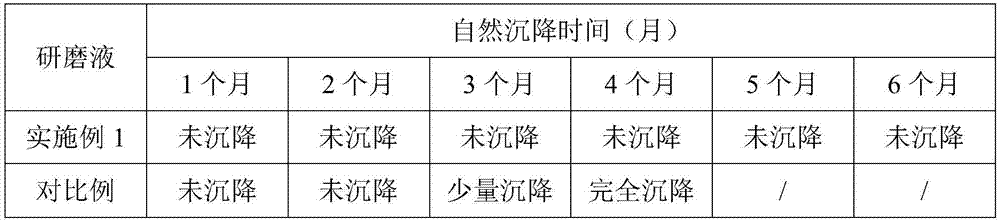

Examples

Embodiment 1

[0021] In the present embodiment, the water-based diamond grinding liquid in which the abrasive is continuously suspended is composed of the following components in parts by mass: 0.1 part of diamond abrasive (particle size M0 / 0.5, purity 99.5%), nonylphenol polyoxyethylene ether (surface modifier , 0.005 parts each of NP-6 and NP-9, analytically pure) 0.01 part, 1 part of N-methylpyrrolidone (suspension agent, purity 95%) of modified polyurea, N-methylpyrrolidone (analytical pure) 1 part Parts, 30 parts of ethylene glycol (analytical pure), 67.89 parts of deionized water (TDS value less than 0.03mg / L).

[0022] The preparation method of the water-based diamond grinding liquid in which the abrasive is continuously suspended comprises the following steps: accurately taking each component according to the mass fraction, adding nonylphenol polyoxyethylene ether into the diamond abrasive, stirring and ultrasonically dispersing for 10 minutes, ultrasonic power 500W, frequency 40KHz...

Embodiment 2

[0024] In the present embodiment, the water-based diamond grinding liquid in which the abrasive is continuously suspended is composed of the following components in parts by mass: 0.5 part of diamond abrasive (particle size M5 / 10, purity 99.5%), octylphenol polyoxyethylene ether (surface modifier , OP-6 and OP-9 each get 0.25 parts, analytically pure) 0.5 parts, modified polyurea N-methylpyrrolidone (suspending agent, purity 95%) 2 parts, N-methylpyrrolidone (analytical pure) 2 Parts, polyethylene glycol (analytical grade) 40 parts, deionized water (TDS value is less than 0.03mg / L) 55 parts.

[0025] The preparation method of the water-based diamond grinding liquid in which the abrasive is continuously suspended comprises the following steps: accurately taking each component according to the mass fraction, adding octylphenol polyoxyethylene ether to the diamond abrasive, stirring and ultrasonically dispersing for 15 minutes, ultrasonic power 600W, frequency 40KHz; then add pol...

Embodiment 3

[0027] The water-based diamond grinding liquid in which the abrasive is continuously suspended in the present embodiment is composed of the following components in parts by mass: 2 parts of diamond abrasive (particle size M20 / 30, purity 99.5%), nonylphenol polyoxyethylene ether (surface modifier , 0.5 parts each of NP-6 and NP-15, 1 part of analytically pure), 3 parts of N-methylpyrrolidone (suspending agent, purity 95%) of modified polyurea, 3 parts of N-methylpyrrolidone (analytical pure) Parts, polyethylene glycol (analytical grade) 50 parts, deionized water (TDS value is less than 0.03mg / L) 41 parts.

[0028] The preparation method of the water-based diamond grinding liquid in which the abrasive is continuously suspended comprises the following steps: accurately taking each component according to the mass fraction, adding nonylphenol polyoxyethylene ether into the diamond abrasive, stirring and ultrasonically dispersing for 10 minutes, ultrasonic power 800W, frequency 40KH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com