Rubber modified phase change heat conduction interface material and preparation method

A technology of phase change heat conduction and interface materials, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve problems such as difficult to use, unable to meet users' high-speed production efficiency, damage, etc., to achieve convenient use, excellent thermal conductivity, The effect of low thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

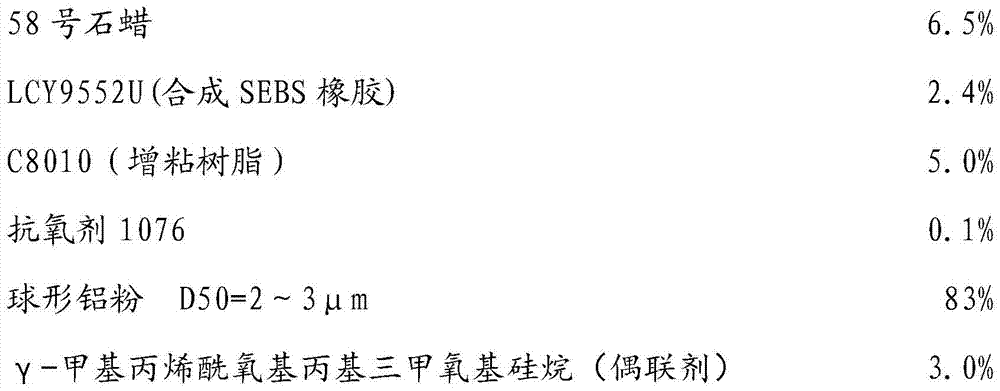

[0033] A rubber-modified phase-change thermal interface material, comprising the following raw materials by weight:

[0034]

[0035] A method for preparing a rubber-modified phase-change thermal interface material, comprising the steps of:

[0036] (1) Weigh 65g of No. 58 paraffin-based phase change resin, 24g of LCY9552U synthetic SEBS rubber, 50g of C8010 tackifying resin, and 1g of antioxidant 1076. After mixing evenly, heat up to 70°C and stir for 30-45 minutes , to obtain paste;

[0037] (2) Weigh 30g of γ-methacryloxypropyltrimethoxysilane (coupling agent) coupling agent, add it to the paste obtained in step (1), stir for 15 minutes, until the coupling agent The coupling agent is completely dissolved to obtain mixture A;

[0038] (3) Raise the temperature to 120°C, weigh 830g of spherical heat-conducting aluminum powder particles with D50=2-3μm, slowly add it to the mixture A obtained in step (3), stir for 60-90 minutes, and after mixing evenly, vacuum After defoa...

Embodiment 2

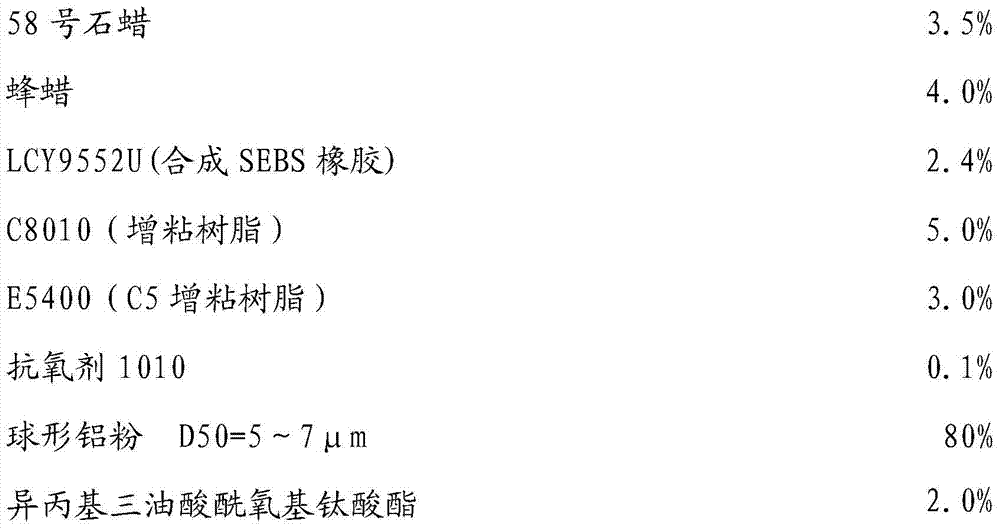

[0040] A rubber-modified phase-change thermal interface material, comprising the following raw materials by weight:

[0041]

[0042] A rubber-modified phase-change thermal interface material, comprising the steps of:

[0043] (1) Weigh the following raw materials: No. 58 paraffin-based phase change resin 35g, beeswax 40g, LY9552U modified rubber 24g, C8010 tackifying resin 50g, E5400 tackifying resin 30g, 1010 antioxidant 1g, isopropyl 20g of trioleic acyloxy titanate coupling agent, 800g of spherical aluminum powder heat-conducting particles;

[0044](2) heating up the basic phase-change resin, modified rubber, tackifying resin, and antioxidant weighed in step (1) to 70° C., mixing evenly, and stirring for 30 to 45 minutes to obtain a paste;

[0045] (3) Add the coupling agent weighed in step (1) to the paste obtained in step (2), and stir for ≥10 minutes until the coupling agent is completely dissolved to obtain mixture A;

[0046] (4) Raise the temperature to 120°C, t...

Embodiment 3

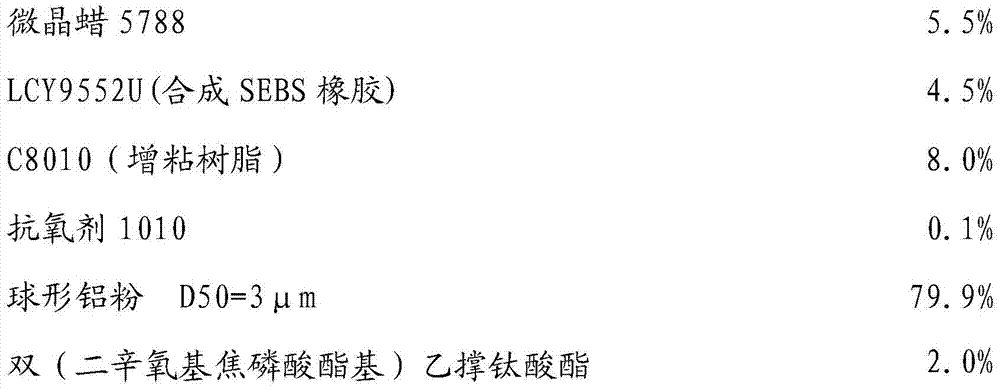

[0048] A rubber-modified phase-change thermal interface material, comprising the following raw materials by weight:

[0049]

[0050] A method for preparing a rubber-modified phase-change thermal interface material, comprising the steps of:

[0051] (1) Weigh the following raw materials: 55g of microcrystalline wax 5788 basic phase change resin, 45g of LY9552U modified rubber, 80g of C8010 tackifying resin, 1g of 1010 antioxidant, bis(dioctyloxypyrophosphate) ethyl 20g of titanate coupling agent, 799g of spherical aluminum powder heat conducting particles;

[0052] (2) heating up the basic phase-change resin, modified rubber, tackifying resin, and antioxidant weighed in step (1) to 70° C., mixing evenly, and stirring for 30 to 45 minutes to obtain a paste;

[0053] (3) Add the coupling agent weighed in step (1) to the paste obtained in step (2), and stir for ≥10 minutes until the coupling agent is completely dissolved to obtain mixture A;

[0054] (4) Raise the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com