Steel plate for thick-gauge high-toughness EH36-level ocean platform and manufacturing method

An offshore platform, high toughness technology, applied in the field of hot rolling and heat treatment of steel plates, can solve the problems of increasing production costs, and achieve the effects of saving production costs, moderate strength margin, and low welding sensitivity index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0033] The slab with a thickness of 300mm is put into the heating furnace, the slab exit temperature is 1210°C, the heating time is 240 minutes, and the soaking time is 50 minutes; the rough rolling start temperature is 1170°C, the finish rolling start temperature is 910°C, The thickness is 120mm, the final rolling temperature is 860°C, the ACC final cooling temperature is 660°C, the cooling rate is 8°C / s, the normalizing temperature is 880°C, and the holding time is 20min. The (weight percent) chemical composition of the finished slab is: C0.17%, Si0.38%, Mn1.48%, P0.009%, S0.003%, Alt0.026%, Nb0.040%, V0.050 %, Ti0.014%, Ni0.30%, La0.0015%, and the balance is Fe and unavoidable impurities. Rolled into a steel plate with a thickness of 80 mm, the detailed rolling and heat treatment process is shown in Table 1, and its mechanical properties are shown in Table 2.

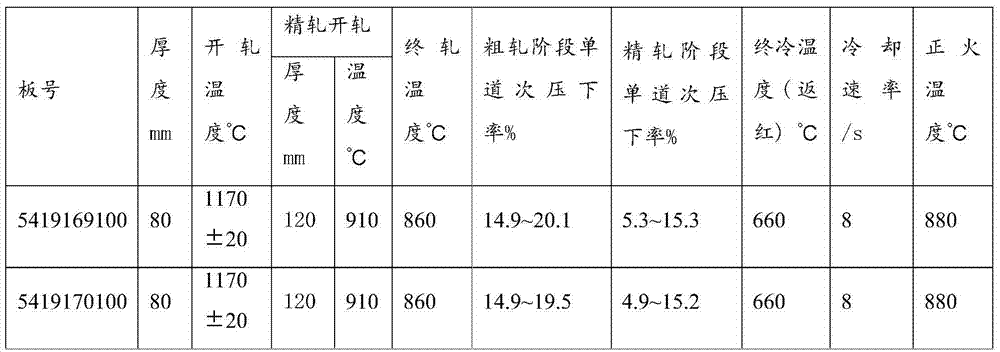

[0034] Table 1 Rolling and heat treatment process

[0035]

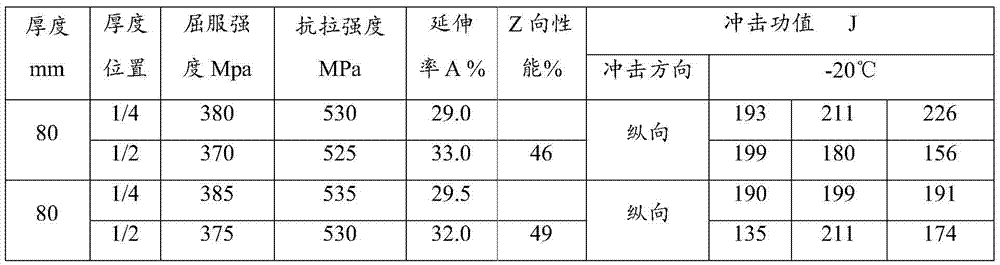

[0036] Table 2 Mechanical properties of steel pl...

Embodiment 2

[0039]Put the slab with a thickness of 300mm to be rolled into the heating furnace. The slab exit temperature is 1210°C, the heating time is 240 minutes, the soaking time is 50 minutes, the rough rolling start temperature is 1170°C, and the finish rolling start temperature is 1170°C. The rolling temperature is 910°C, the starting rolling thickness is 140mm, the final rolling temperature is 870°C, the final cooling temperature is 660°C, the cooling rate is 5°C / s, the normalizing temperature is 860°C, and the holding time is 30min. The (weight percent) chemical composition of the finished slab is: C0.17%, Si0.38%, Mn1.48%, P0.009%, S0.003%, Alt0.026%, Nb0.040%, V0.050 %, Ti0.014%, Ni0.30%, La0.0015%, and the balance is Fe and unavoidable impurities. Rolled into a steel plate with a thickness of 100 mm, the detailed rolling and heat treatment process is shown in Table 3, and its mechanical properties are shown in Table 4.

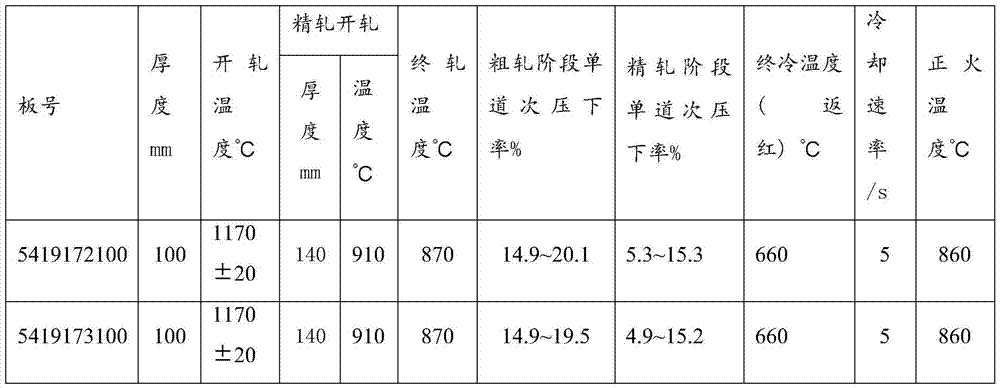

[0040] Table 3 Rolling and heat treatment process

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com