Electroplating solution composition capable of being used for improving salient point coplanarity

A technology of electroplating solution and composition, applied in the direction of circuits, semiconductor devices, etc., can solve the problem that the packaging method cannot meet the requirements, and achieve the effect of good coating coplanarity and smooth coating morphology

Active Publication Date: 2016-03-30

SHANGHAI SINYANG SEMICON MATERIALS

View PDF6 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

As the feature size of the chip line width is getting smaller and smaller, the number of I / Os of the chip is increasing, and the traditional packaging method can no longer meet the requirements. An advanced wafer 3D interconnection packaging technology (WLP) came into being.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-4

[0039] The electroplating solution composition is configured according to the concentration formula in Table 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

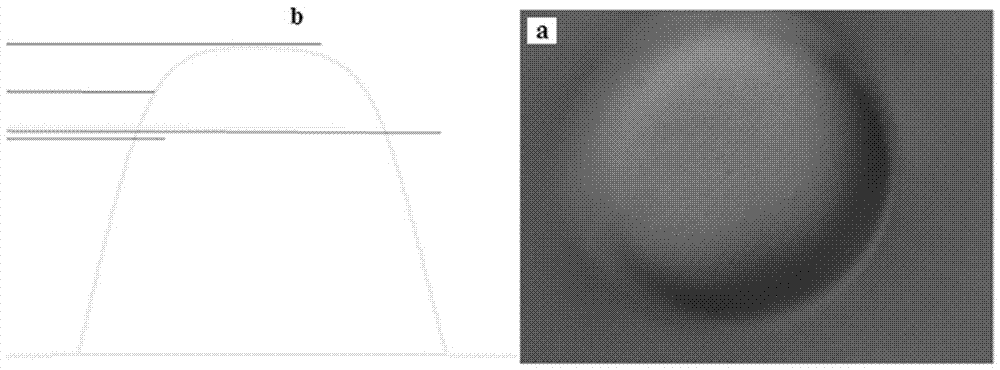

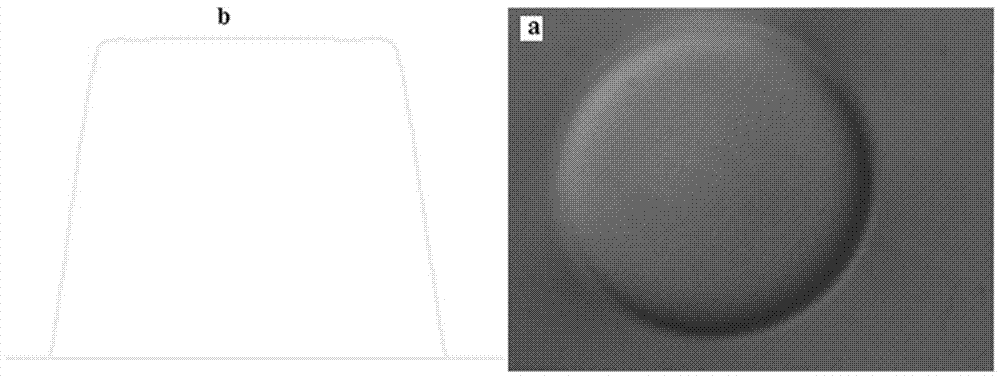

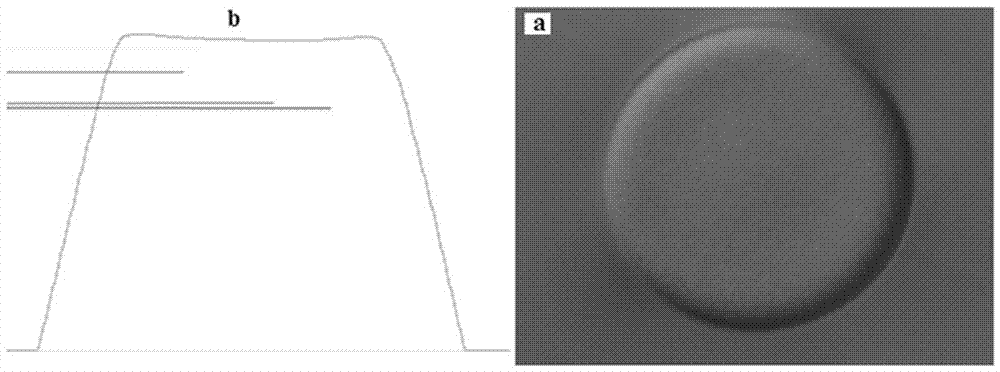

The invention discloses an electroplating solution composition capable of being used for improving salient point coplanarity. The electroplating solution composition comprises a leveling agent which is polymer with positive electricity, wherein a polymeric monomer of the polymer comprises the following monomer structure: FORMULA as shown in the specification, wherein R1 on N is selected from alkyls of C1-4, and R2 on the N is selected from the alkyls of C1-4. During high-speed electroplating (2.5 mu m / min), the electroplating solution composition provided by the invention still can keep relatively good plating coplanarity which is much smaller than an industrial required value by 3%; the plating is flat in feature, can be used for copper pillar salient point electroplating of a 3D interconnecting and packaging process, and has a good market prospect.

Description

technical field [0001] The invention belongs to the field of semiconductor chip packaging, and relates to a copper bump electroplating process for 3D interconnection packaging, in particular to an additive for improving the coplanarity of bumps. Background technique [0002] The traditional interconnection process technology of semiconductor chips is a thin film process of aluminum process. However, when the line width is less than 0.18um, reliability problems such as signal delay and electromigration seriously affect the reliability of integrated circuits. In 1999, IBM took the lead in developing the damascenes chip copper interconnection process, and achieved mass production of the chip copper interconnection process in 2000. Copper metal is considered to be an excellent chip interconnection material due to its excellent electrical conductivity, thermal conductivity, low melting point and easy extension. As the feature size of the chip line width is getting smaller and s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C25D3/38C25D7/12

CPCC25D3/38C25D7/12

Inventor 王溯孙红旗

Owner SHANGHAI SINYANG SEMICON MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com