Water-based formula and production process of photovoltaic lithium ion battery electrode

A lithium-ion battery and production process technology, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve problems such as troublesome and poor effect, and achieve excellent charging performance, good slurry fluidity, and no coating. bubble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific examples.

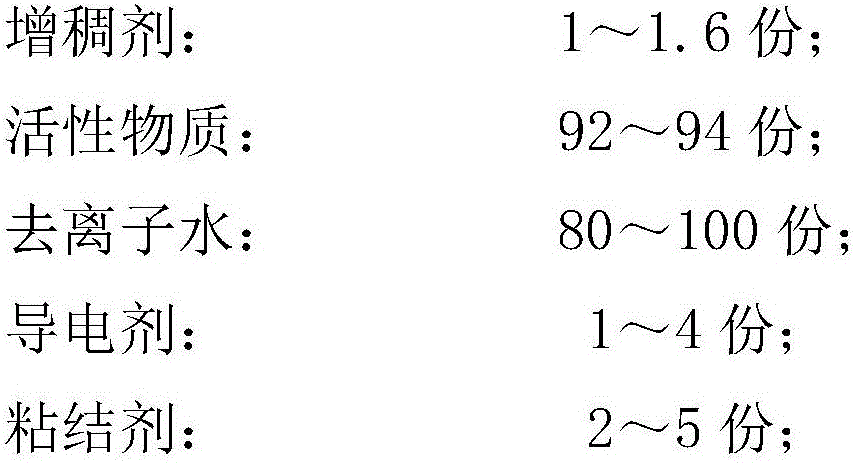

[0031] An aqueous composition of photovoltaic lithium-ion battery electrodes, made of the following components in parts by weight,

[0032]

[0033] The low temperature resistant agent comprises the following components in parts by weight: 0.1-0.5 parts of potassium chloride, 0.1-0.5 parts of tin methanesulfonate and 0.01-0.08 parts of cobaltous tungstate.

[0034] A production process for an aqueous composition of photovoltaic lithium-ion battery electrodes,

[0035] 1). Take 40-60% deionized water and add 0.5-2% edible instant CMC to make glue, add it to the mixer bucket and stir for 0.5-2 hours to prepare the thickener for later use;

[0036] 2). Soaking active substances by batch feeding: put 50% of the total amount of active substances into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com