Weaving method for novel mica base cloth

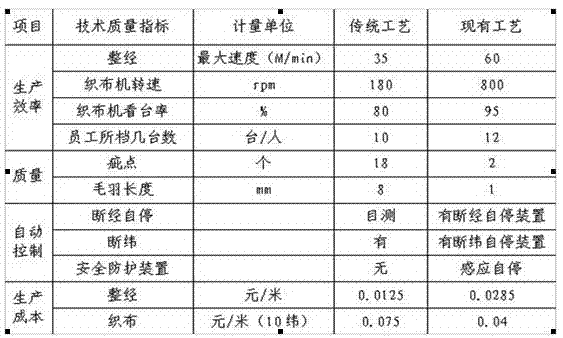

A technology of mica and base fabric, which is applied in textiles, papermaking, fabrics, textiles, etc., can solve the problems of difficult quality control, unfavorable bonding of ultra-thin mica base fabric and mica paper weaving, easy weft skew or weft shift of weft yarn, etc. Achieve a high degree of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with embodiment.

[0023] Present embodiment provides the method utilizing air-jet loom to weave special ultra-thin mica base cloth, and this method comprises the following steps:

[0024] (1) Place the non-alkali glass fiber bobbin on the creel, thread it through the screen reed, split reed, steel reed, and wind it on the warp beam. The alkali metal content of the alkali glass fiber yarn is ≦0.8%, the fiber diameter is 4-5.5μm, the width of the warp beam depends on the width of the glass fiber cloth, generally 916mm-1026mm, and the number of warp yarns also depends on the type of glass fiber cloth Depending on the warp density, usually 2100-2300, the linear density is 4.2-11.3tex, the average winding speed is 60M / min, and the length of warp yarn wound by each warp beam is 30000M; the warping sand frame is equipped with infrared rays The sensor has the function of self-stop when the warp is broken;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com