Multi-stage disc type solid-liquid separator or dust collector

A solid-liquid separation and dust removal technology, which is applied in separation methods, dispersed particle separation, centrifugal separation of water/sewage treatment, etc., can solve the problems of complex equipment structure, high rotation speed, and small ventilation, and achieve high separation efficiency and retention. long time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

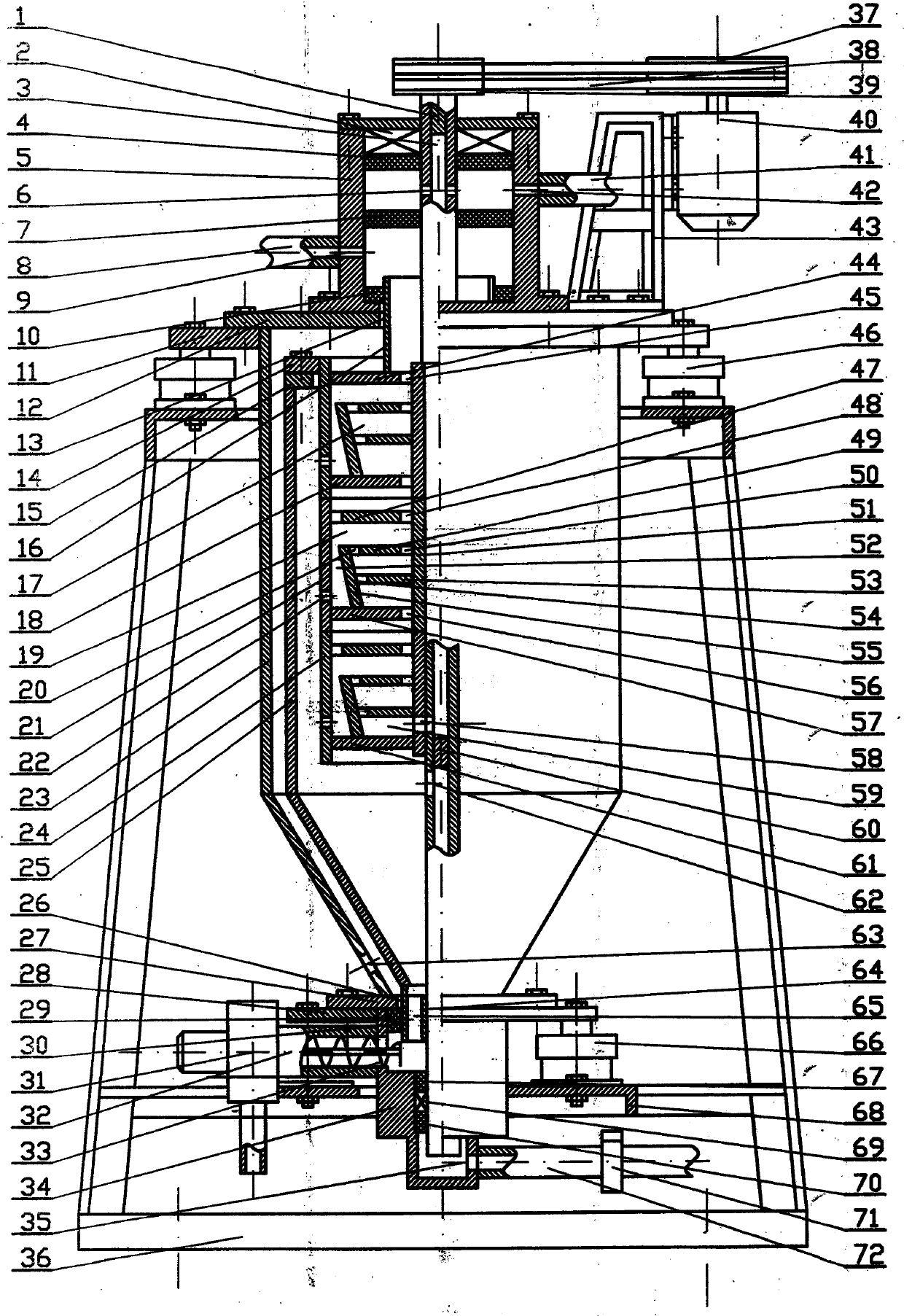

[0021] Below in conjunction with accompanying drawing the embodiment of multistage disk type solid-liquid separation of the present invention or dedusting machine is described in detail:

[0022] For the convenience of description, this specific embodiment is described with a solid-liquid separator as a specific implementation mode, that is, the raw material to be separated is sewage mixed with solid and liquid as an example, and when it comes to a dust collector for dust and gas separation, the raw material to be separated is replaced by For dust, these all belong to those skilled in the art and can make corresponding changes according to the following specific implementation methods.

[0023] The multi-stage disc type solid-liquid separation or dedusting machine of the present invention includes a frame 36, an organic casing 23 is arranged on the frame 36, an upper end cover 12 is arranged on the upper end of the casing 23, and an upper bearing seat is arranged on the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com