Novel bridge for melting snow through waste heat of power plant and construction method

A thermal melting and bridge technology, used in bridges, bridge parts, bridge construction, etc., can solve problems such as traffic congestion, prone to traffic accidents, and impassable vehicles, to ensure roads, save the cost of artificial snow removal, and reduce snow. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

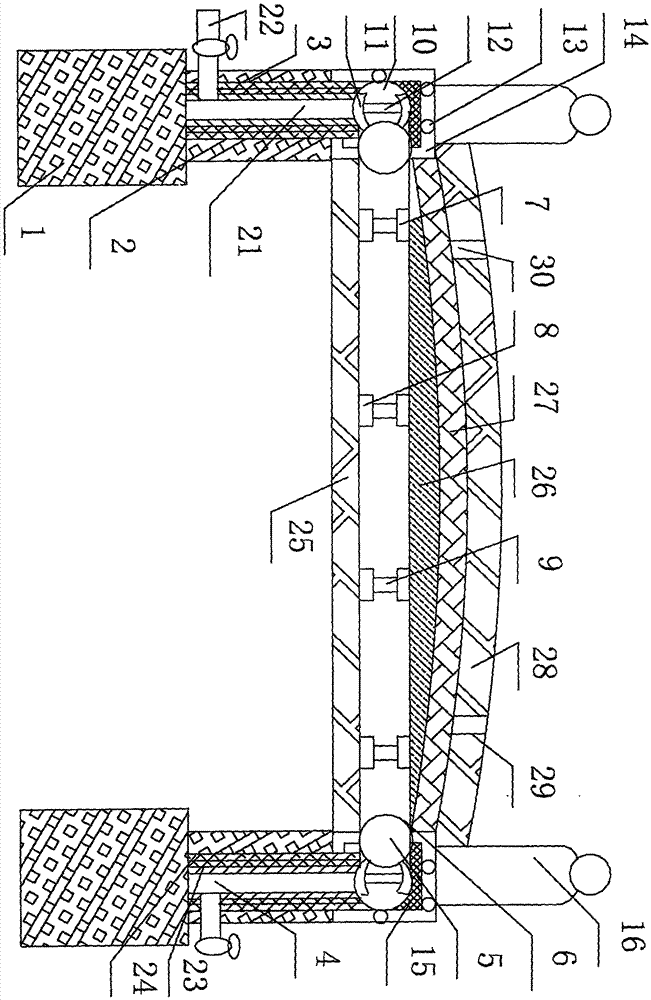

[0024] A new type of bridge that melts ice and snow using waste heat from a power plant. Its composition includes: a bridge pile foundation 1, the bridge pile foundation is connected to a bridge pier 2, and a group of vertical through holes 3 are opened on the bridge pier. The main heat delivery pipe 4 is inserted into the through hole, and the main heat delivery pipe is connected to the horizontal branch heat transfer pipe 5. The horizontal branch heat transfer pipe is provided with a group of connection holes 6, and the connection holes are connected to a group of cross-branched heat transfer pipes. The top of the heat release tube is connected to the upper arc-shaped connecting plate 7, the bottom of the inside of the heat release tube is connected to the lower arc-shaped connecting plate 8, and the upper arc-shaped connecting plate is connected to the The lower arc-shaped connecting plates are supported and connected by 1-5 pillars 9, and the heat release pipes are laid in ...

Embodiment 2

[0026] In the new bridge that melts ice and snow using waste heat from a power plant described in Example 1, the main heat transfer pipe is connected to the transverse branch heat transfer pipe through an elbow 10, and the part of the elbow that is arranged horizontally Both the top and the bottom of the interior are connected to arc-shaped connecting plates 11, and support columns 12 are connected between the arc-shaped connecting plates. Because the elbow is supported by arc-shaped connecting plates and supporting columns, it is safe to use and will not be crushed to ensure smooth air intake.

Embodiment 3

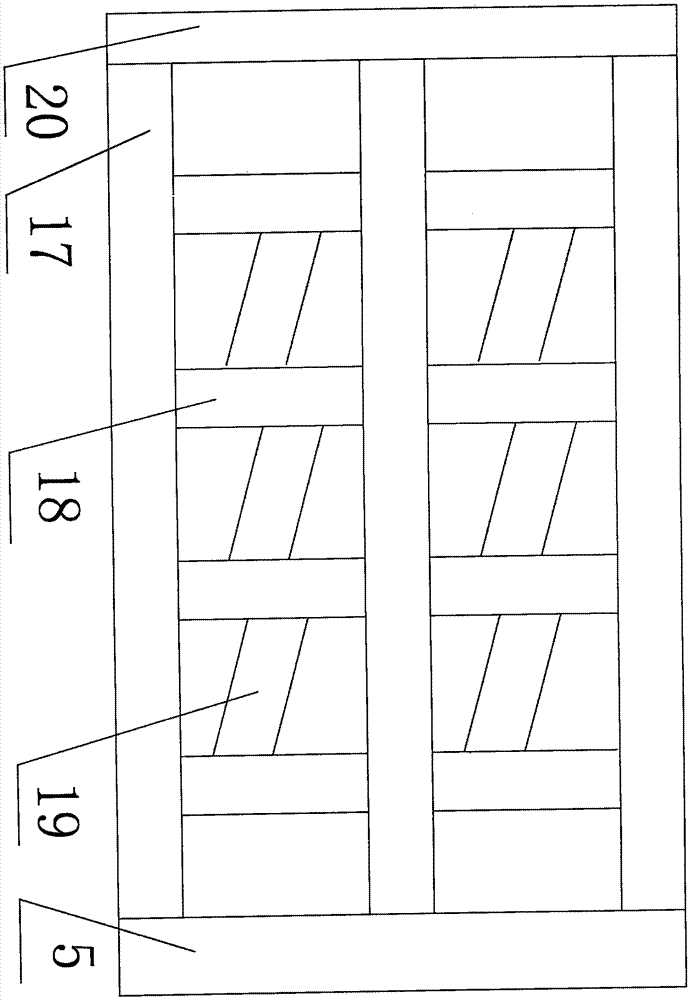

[0028] In the novel bridge using waste heat from a power plant to melt ice and snow described in Example 1, the transverse branch heat transfer tubes are installed in a steel frame, and the steel frame includes a group of square brackets 13, and between the square brackets The steel bar frame is connected to the concrete 15 through the horizontal steel bar 14, and the steel bar frame and the concrete are both connected to the side bridge guardrail 16.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com