Groove-type sheet-pile

A sheet pile and trough technology, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problems of blocking the ecological chain, small contact area at the butt joint, and easy damage at the joint, so as to maintain the ecological balance and increase the Large contact area, not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

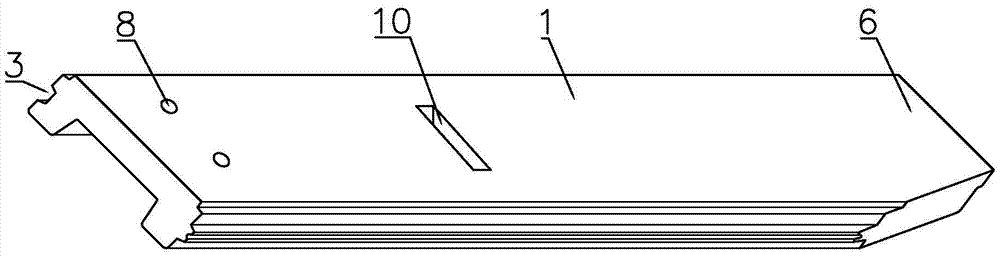

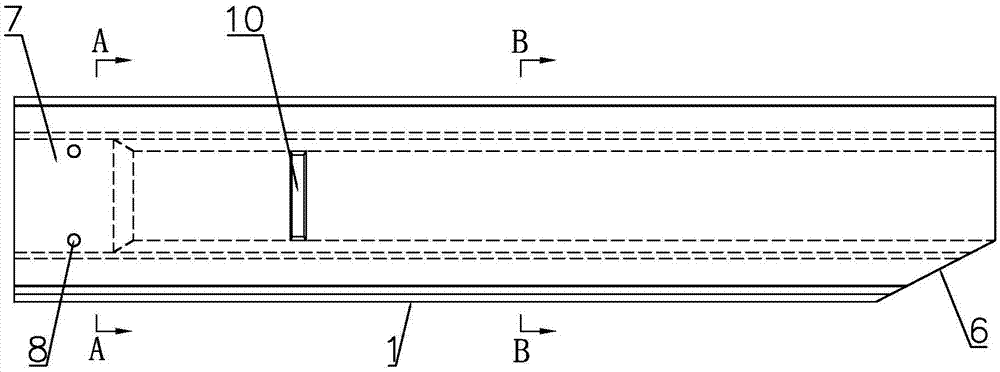

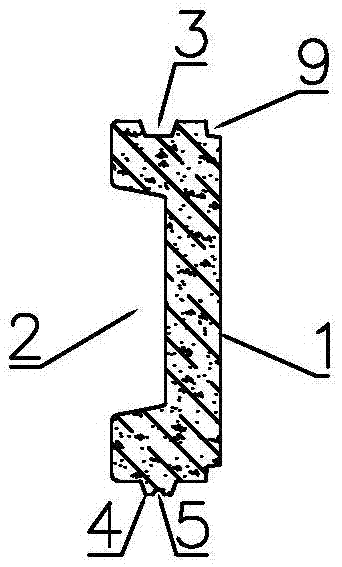

[0023] Such as Figure 1-Figure 5 As shown, a grooved sheet pile includes a plate-shaped pile body 1, the front of the pile body 1 is provided with a longitudinal groove 2, and one side of the pile body 1 is provided with a longitudinal groove I3, The other side of the pile body 1 is provided with a strip-shaped protrusion 4 corresponding to the groove I3. The main reinforcement of the sheet pile can be fully prestressed, semi-prestressed or non-prestressed main reinforcement.

[0024] The bottom of the groove I3 and / or the strip-shaped protrusion 4 is provided with a groove II5. The cross section of the groove II5 can be trapezoidal or semicircular. After the adjacent sheet piles are butted, if one side If groove II5 is provided, trapezoidal or semicircular water stop holes will be formed, and if groove II5 is provided on both sides, hexagonal or circular water stop holes will be formed. In this embodiment, the groove II5 is arranged on the strip-shaped protrusion 4 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com