A Self Cooling Electric Auxiliary Feed Water Pump

An electric auxiliary and feed pump technology, applied in radial flow pumps, pumps, pump components, etc., can solve the problems of complex structure of auxiliary feed pumps, troublesome maintenance, influence on safe operation of equipment, etc., to improve anti-cavitation performance, reduce Influence, effect of structural optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

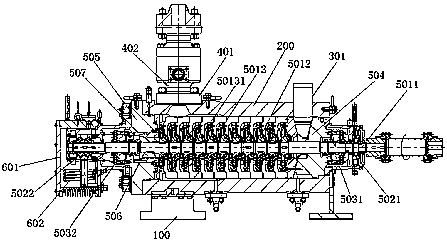

[0021] Such as figure 1 As shown, a self-cooling electric auxiliary feed water pump includes: a pump base part 100, the pump base part is integrally cast, rigid and reliable, and is provided with a lifting device that can rotate 360 degrees; a cylinder 200 is arranged on the pump base Above the component 100, the top of the cylinder 200 is respectively provided with an inlet formed by an inlet flange 301 and an outlet formed by an outlet flange 401, and the inlet and outlet are perpendicular to the axis of the cylinder 200; The end is supported on the section of the cylinder, and the non-driving end is supported on the outer circle of the cylinder, which has sufficient rigidity to ensure the reliable operation of the pump. The supporting part is installed on the pump base part 100 through bolts and connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com