Damping type valveless hydraulic synchronous servo system

A hydraulic synchronization and servo system technology, applied in the direction of servo motors, fluid pressure actuators, mechanical equipment, etc., can solve the problems of low synchronization accuracy, complex oil circuits, leakage pollution, etc., achieve the effect of improving accuracy and solving difficult maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

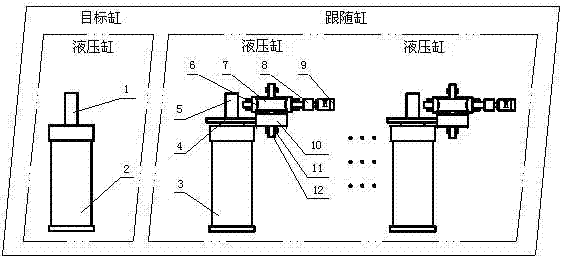

[0027] A damping valveless hydraulic synchronous servo system, which uses a valveless system composed of a servo motor and a variable pump to drive multiple hydraulic cylinders on the valveless hydraulic parallel synchronous circuit, and sensors are used on each parallel branch to monitor the speed, pressure and The displacement is used for data collection, and the controller compares and analyzes the data; in each parallel branch, the hydraulic cylinder on the first branch is the target cylinder, and the hydraulic cylinders on the other branches are follower cylinders, and friction is added to the cylinder heads of the follower cylinders The resistance device adjusts the movement speed of the output end of each cylinder through the friction resistance device to realize the synchronization of displacement, speed and pressure.

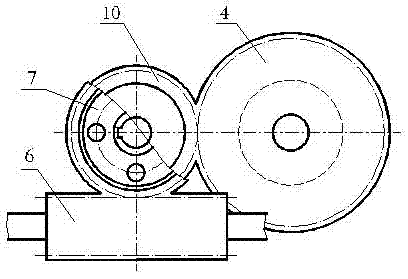

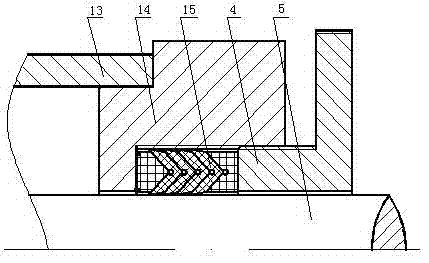

[0028] The frictional resistance device includes a gear pressing block mechanism and a V-shaped sealing ring. The gear pressing block is connected to th...

Embodiment 2

[0040] A damping valveless hydraulic synchronous servo system, which uses a valveless system composed of a servo motor and a variable pump to drive multiple hydraulic cylinders on the valveless hydraulic parallel synchronous circuit, and sensors are used on each parallel branch to monitor the speed, pressure and The displacement is used for data collection, and the controller compares and analyzes the data; in each parallel branch, the hydraulic cylinder on the first branch is the target cylinder, and the hydraulic cylinders on the other branches are follower cylinders, and friction is added to the cylinder heads of the follower cylinders The resistance device adjusts the movement speed of the output end of each cylinder through the friction resistance device to realize the synchronization of displacement, speed and pressure. There are four parallel circuits.

[0041] The frictional resistance device includes a gear pressing block mechanism and a V-shaped sealing ring. The gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com